Saponifying agent for organic rare-earth extraction agents and application method of saponifying agent

A rare earth organic and application method technology, applied in the direction of improving process efficiency, can solve the problems of unfavorable large-scale production, high production cost, large amount of ammonia nitrogen, etc., achieve high quality, reduce consumption, and save production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

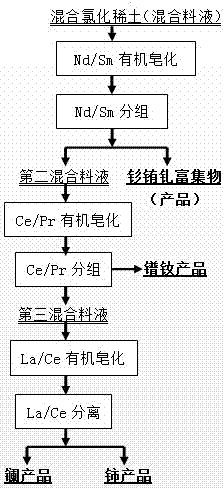

Image

Examples

Embodiment 1

[0031] (1) Add 6m³ of sodium carbonate aqueous solution with a molar concentration of 2mol / L in the first stirring tank, and then filter, add 4m³ of sodium hydroxide with a molar concentration of 4mol / L in the second stirring tank, let it stand, and filter The final sodium carbonate solution is poured into the second stirring tank, mixed with the sodium hydroxide solution prepared in advance, and the saponification agent is obtained after stirring evenly, which is put into the high-level tank for standby; in addition, the organic phase sulfonated kerosene and organic extractant P507 ;

[0032] (2) Add the saponification agent, organic phase, organic extractant and mixed rare earth chloride mixture liquid into the saponification tank, and under the condition of slow stirring, control the flow rate of the organic phase to 28~32L / min, The degree of saponification of the organic extractant is 0.2-0.24 N / L, the flow rate of the saponification agent is 1.54-1.76 L / min, the flow rate...

Embodiment 2

[0036](1) Add 6m³ of sodium carbonate aqueous solution with a molar concentration of 2mol / L in the first stirring tank, and then filter, add 4m³ of sodium hydroxide with a molar concentration of 4mol / L in the second stirring tank, let it stand, and filter The final sodium carbonate solution is poured into the second stirring tank, mixed with the sodium hydroxide solution prepared in advance, and the saponification agent is obtained after stirring evenly, which is put into the high-level tank for standby; in addition, the organic phase sulfonated kerosene and organic extractant P507 ;

[0037] (2) Add the saponification agent, organic phase, organic extractant and mixed rare earth chloride mixture liquid into the saponification tank, and under the condition of slow stirring, control the flow rate of the organic phase to 28~32L / min, The degree of saponification of the organic extractant is 0.2-0.24 N / L, the flow rate of the saponification agent is 1.54-1.76 L / min, the flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com