Ball-milling and acid-leaching method for positive electrode active material of waste lithium ion battery

A cathode active material, a technology for lithium ion batteries, applied in the field of lithium ion batteries, can solve problems such as short process, achieve the effects of efficient leaching, shortening leaching time, and improving leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

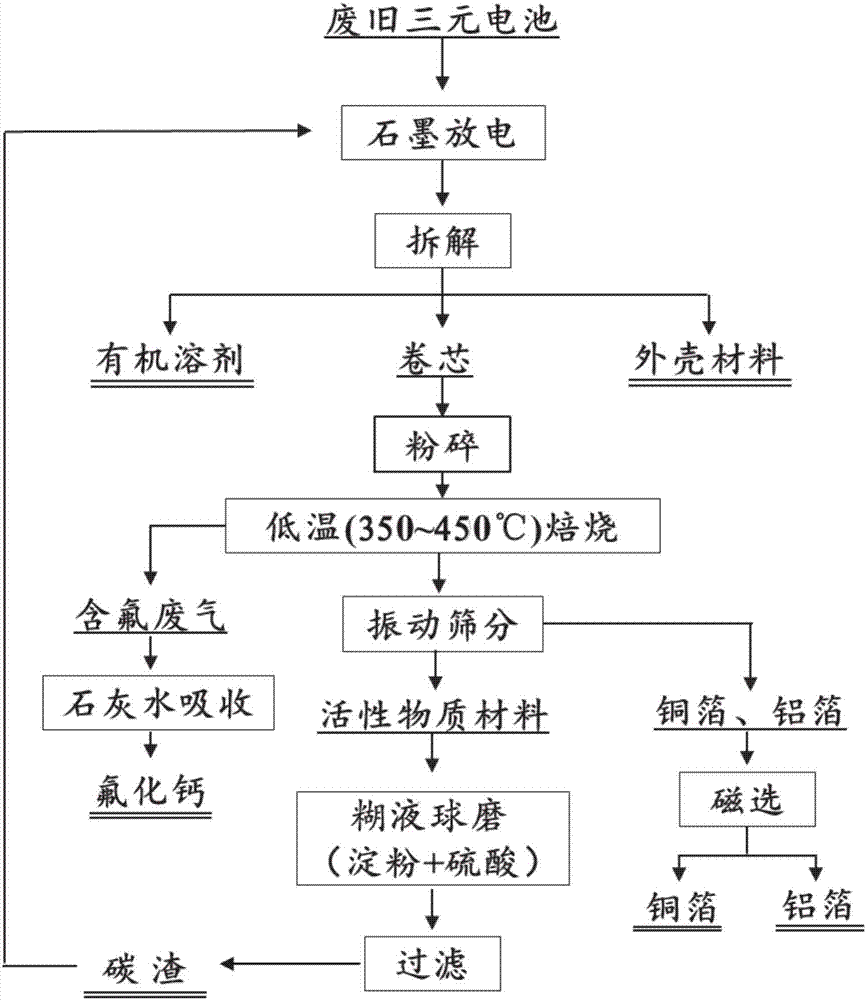

Image

Examples

Embodiment 1

[0046] Take some lithium cobalt oxide batteries for used mobile phones, put them into the powder containing waste carbon slag and discharge them, pick them up when the voltage is lower than 1V, cut off the shell, drain the remaining electrolyte, and take out the winding core. Preliminarily crush the winding core, put it into a roasting furnace and heat it to 400°C, burn off the binder on the pole piece and most of the negative electrode carbon material in the air atmosphere, and absorb the tail gas with a lime solution. The sintered solid mixture is taken out and sieved, the copper foil and aluminum foil fragments are on the sieve, and the cathode active material containing lithium cobalt oxide is mainly on the under sieve.

Embodiment 2

[0048] Weigh 50g of starch, add 1L of deionized water, stir continuously and heat to 70°C until the system becomes a stable paste, named as S1 solution.

Embodiment 3

[0050] Weigh 60g of starch, add 1L of deionized water, stir continuously and heat to 70°C until the system becomes a stable paste, named as S2 solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com