Fe series selective hydrogenation catalyst, and preparation method and application thereof

A technology for selective hydrogenation and catalysts, which is applied in the fields of hydrogenation to hydrocarbons, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The problems of low acetylene conversion rate, etc., can achieve the effect of high olefin increment, mild hydrogenation activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Weigh 100ml of a clover-shaped α-alumina carrier of Φ4.5×4.5mm, and place it in a 1000ml beaker. Take ferric nitrate, dissolve it in 60ml of deionized water by heating, adjust the pH value to 2.5, impregnate the equal volume on the surface of the carrier, shake the carrier quickly for 6 minutes, let it stand for 30 minutes until the adsorption equilibrium, and completely seal the mouth of the beaker with plastic wrap , aged in a water bath at 60°C for 30 minutes, and then in an oven according to the procedure: Dry the catalyst, move the catalyst into an evaporating dish, and activate the catalyst in a muffle furnace using a temperature-programmed method. The activation procedure: Weigh lanthanum nitrate and impregnate according to the above preparation steps. The physical properties of the catalyst are shown in Table 1.

[0067] Evaluation method:

[0068] Catalyst performance evaluation was carried out on a 10ml micro-reactor device. The catalyst was crushed in ...

Embodiment 2

[0075] At 50°C, the NaAlO 2 solution and ZrCl 4 The solution was stirred and mixed, then neutralized with nitric acid solution, stirred for 10 hours, and uniform Al-Zr particles were formed by co-precipitation. The resultant was filtered and the Na in it was washed with deionized water + and Cl - Ions, and then add an appropriate amount of polyvinyl alcohol with a mass concentration of 15% as a pore-forming agent, and knead it into shape. Dry at 130°C for 2 hours, and calcined at 650°C for 4 hours to obtain a Zr-Al composite support, the mass ratio of alumina to zirconia in the support is 4:1.

[0076] Weigh 100ml of the composite carrier and place it in a 1000ml beaker. Take ferric chloride and potassium chloride, heat and dissolve in 100ml deionized water, adjust the pH value to 2.0, impregnate the liquid at a temperature of 80°C, impregnate the excess onto the carrier, shake the beaker for 10 minutes, filter off the excess impregnating liquid, and keep the catalyst at 6...

Embodiment 3

[0083] Weigh 100ml of a Φ1.5mm spherical α-alumina carrier. Dissolve ferric nitrate in 40ml of deionized water, adjust the pH value to 3.0, soak the liquid at a temperature of 40°C, spray it on the carrier with a watering can, load it in the drum for 10 minutes to make the active components evenly loaded, and control the loading process in 6 minutes to complete, and then In the oven follow the procedure: Dry the catalyst, move the catalyst into an evaporating dish, and activate the catalyst in a muffle furnace using a temperature-programmed method. The activation procedure: Obtain a catalyst dip.

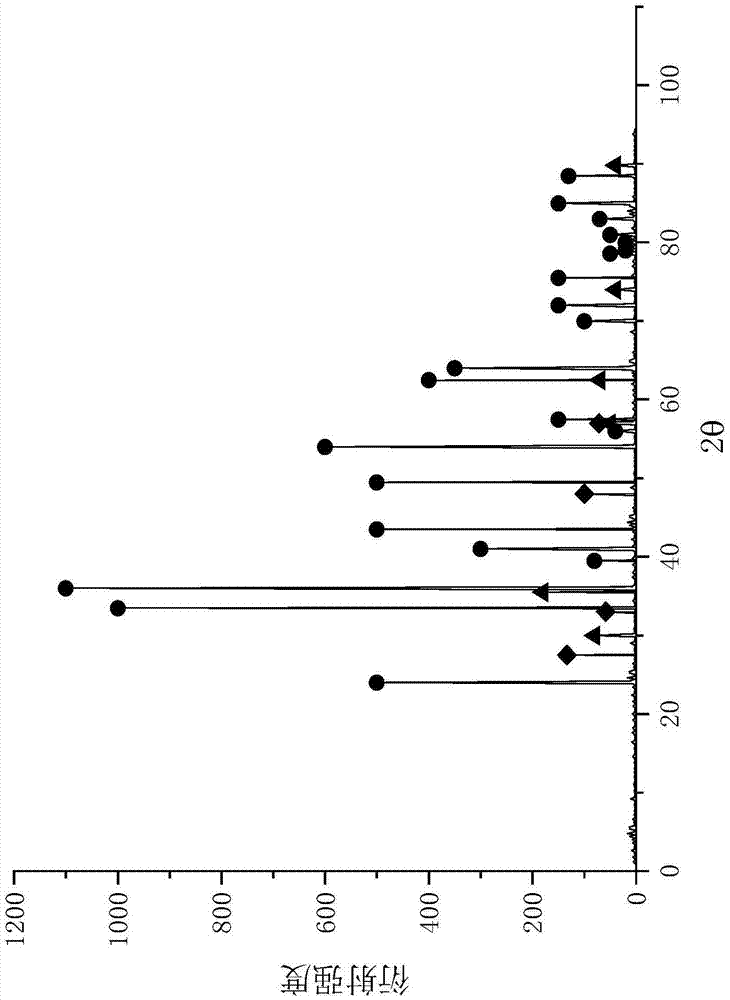

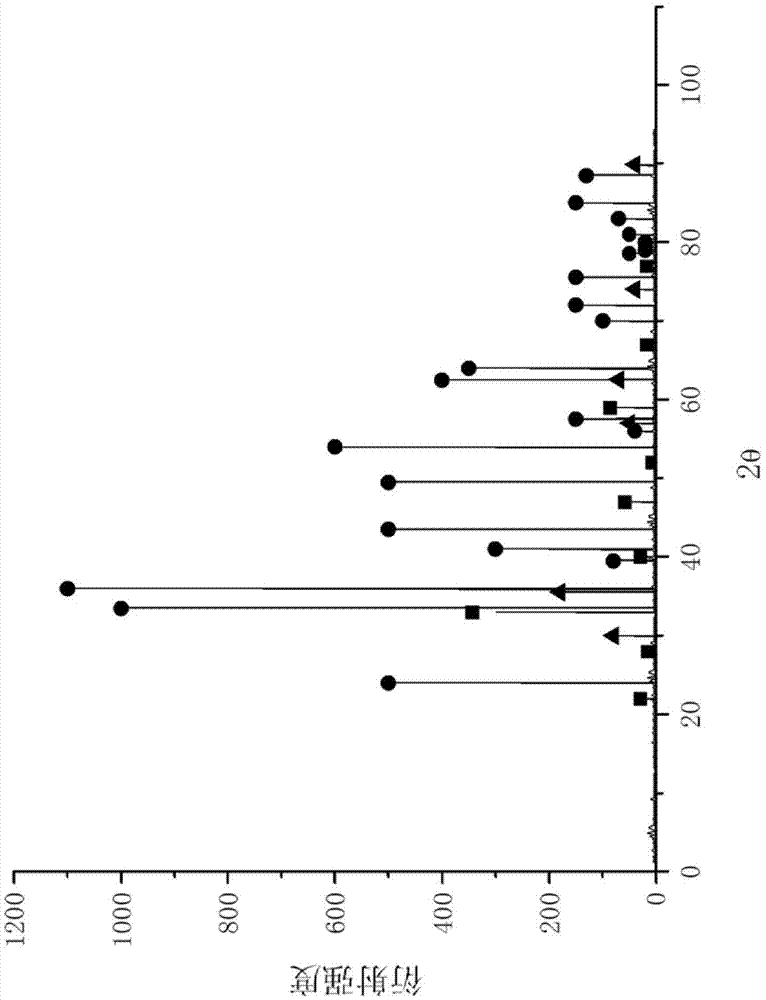

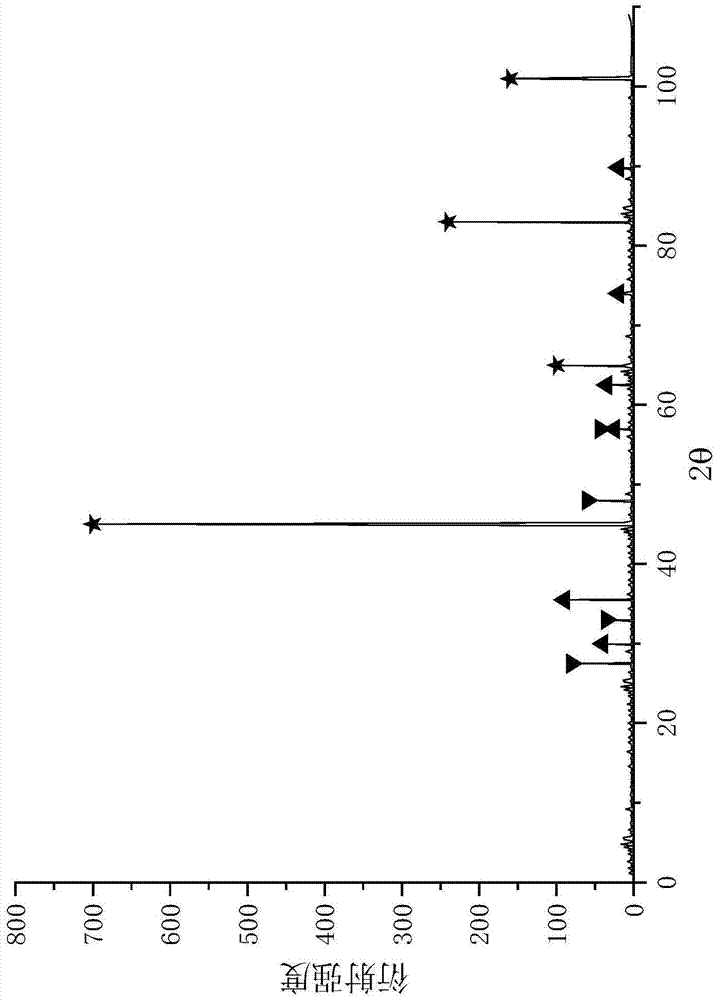

[0084] Using the same method as the first step, take cerium nitrate, dissolve it, spray it on the surface of the catalyst, dry it, and roast it to obtain the final catalyst. Drying procedure: Roasting procedure: The XRD analysis of the catalyst after reduction is as follows: figure 1 shown.

[0085] The physical properties of the catalyst are shown in Table 1.

[0086] Ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com