Preparation method of chromium nitride nanometer powder

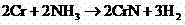

A chromium nitride nano-powder technology, which is applied in the field of nano-powder manufacturing, can solve the problems of long reaction time, burning rate, reaction temperature, difficult control of the reaction process, and pollutant generation, so as to realize automatic industrial production and facilitate automatic industrial production. The effect of continuous production and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

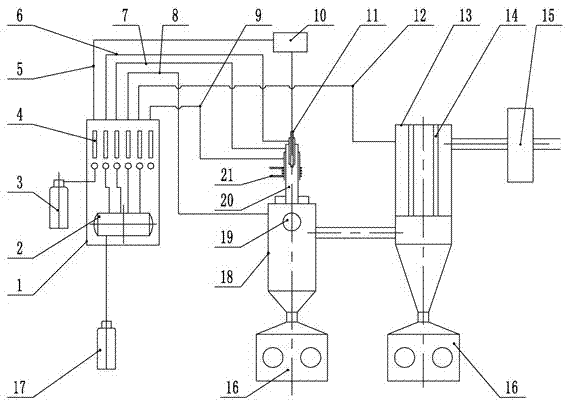

[0030] Such as figure 1 As shown, a high-frequency plasma multifunctional powder production equipment includes a gas flow control cabinet 1, an energy storage tank 2, an ammonia gas cylinder 3, a flow meter 4, a powder feeding gas pipeline 5, an ion gas gas pipeline 6, and an internal Cooling air circuit 7, quenching air circuit 8, external cooling air 9, powder feeder 10, powder feeding gun 11, backflushing air circuit 12, collection device 13, filter element 14, tail gas treatment device 15, packing box 16, argon cylinder 17 , host tank 18, mirror 19, lamps 20 and induction coil 21.

[0031] The gas flow control cabinet 1 is used to detect and control the gas flow required by each channel of the equipment. The energy storage tank 2 is placed inside the gas flow control cabinet 1. One end of the energy storage tank 2 is connected to the argon gas cylinder 17, and the other end is connected to the argon gas cylinder 17. The gas ports are respectively connected to the ion gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com