Dendritic polymer heavy metal trapping agent with chelate-flocculation dual performance and application thereof

A heavy metal scavenger, dual-performance technology, used in flocculation/sedimentation water/sewage treatment, water pollutants, solid adsorbent liquid separation, etc. Good and other problems, to achieve the effect of not easy secondary pollution, fast deposition, fast sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

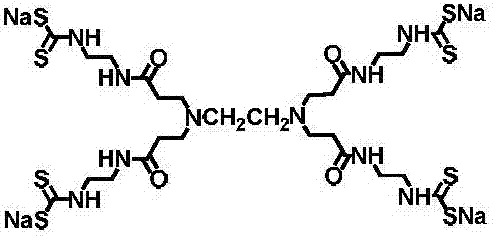

[0035] Embodiment 1: Preparation of terminal dithiocarbamate group 1G polyamidoamine dendrimers

[0036] Slowly add 143.00g (20%, 0.02mol) polyamidoamine (Ethylenediamine core, 1generation, PAMAMdendrimer; M1429. 85, the following abbreviation PAMAM-(NH 2 ) 8 ) in methanol solution, cool down to 5°C, slowly dropwise add 60.91g (50%, 0.40mol) methanol solution of carbon disulfide (M76.14), control the rate of addition, make the temperature of the reaction mixture 8 ), M2018.97), the yield is 99.95%, indicating that the terminal amino group (with -NH 2 The molar ratio of carbon disulfide to the carbon disulfide participating in the reaction is (-NH 2 ):(CS 2 )=1:1. The mother liquor is methanol and unreacted carbon disulfide, which can be reused.

[0037] The resulting PAMAM-(NHCSSH) 8 Add a four-necked flask, then add 35.00g of water, 16.00g (40%, 0.16mol) of sodium hydroxide solution, and react for 2 hours at 50°C to obtain a solid content of about 50% terminal dithiocar...

Embodiment 2

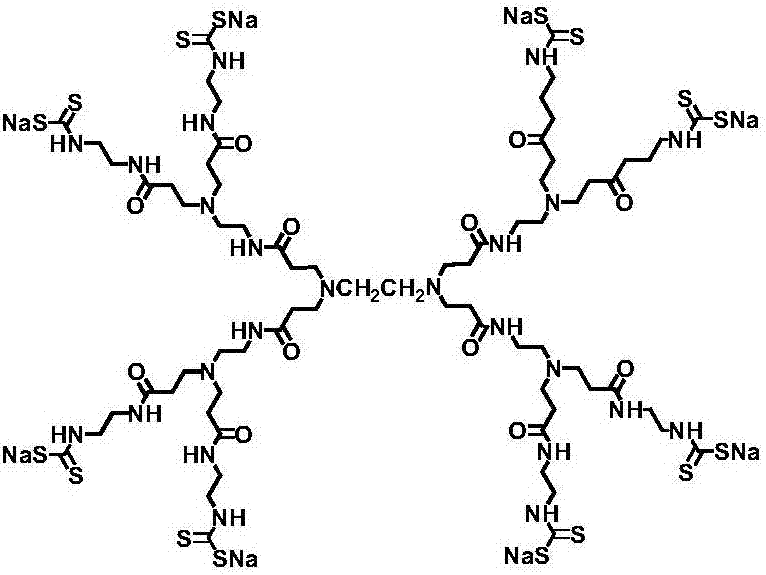

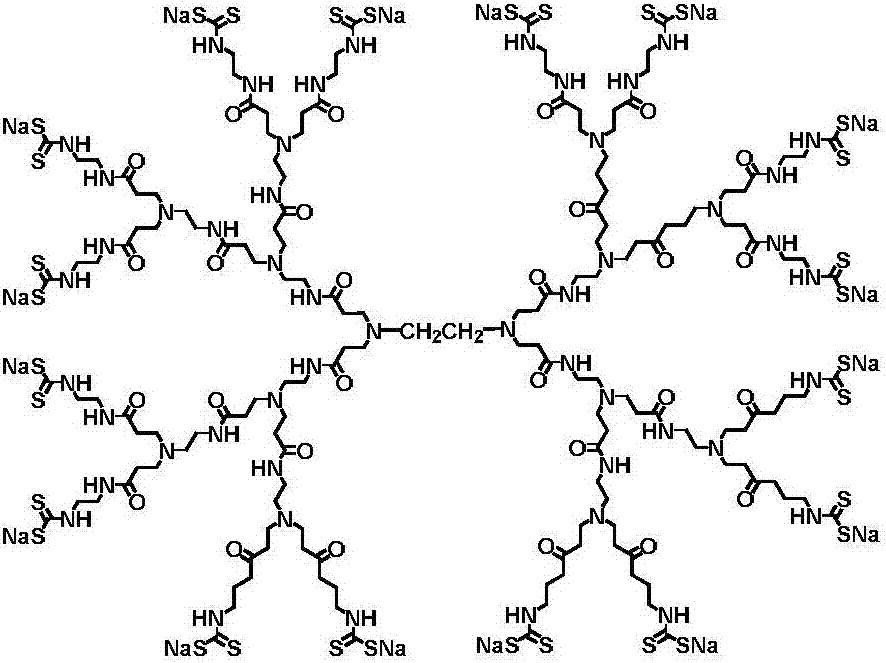

[0040] Example 2: Preparation of terminal dithiocarbamate group 2G polyamidoamine dendrimers

[0041] Slowly add 162.81g (20%, 0.01mol) of the 2nd generation polyamidoamine (Ethylenediamine core, 2generation, PAMAMdendrimer; M3256. 18, the following abbreviation PAMAM-(NH 2 ) 16 ) in methanol solution, cool down to 5°C, slowly dropwise add 73.09g (50%, 0.48mol) methanol solution of carbon disulfide (M76.14), control the rate of addition, make the temperature of the reaction mixture 16 ), M4474.42), yield 99.93%. The mother liquor is a mixed solution of methanol and unreacted carbon disulfide, which can be reused.

[0042] The obtained intermediate PAMAM-(NHCSSH) 16 Add all to the four-necked flask, add 42.00g of water, 16.00g (40%, 0.16mol) of sodium hydroxide solution, and react for 2 hours at 50°C to obtain a solid content of about 50% terminal dithiocarbamate group Polyamidoamine (as PAMAM-(DTC) 16 express).

[0043] The resulting PAMAM-(DTC) 16 The NMR spectrum ( 1...

Embodiment 3

[0045] Embodiment 3: Treatment of circuit board heavy metal wastewater

[0046] A circuit board wastewater: pH 2.6, Cu 2+ 165.282mg·L -1 、Ni 2+ 101.395mg·L -1 , add the heavy metal trapping agent of embodiment 1, 2 and comparative example, stir 5min, precipitate 5min, filter, measure heavy metal concentration, the results are shown in Table 1.

[0047] The results showed that the dosage of 200mg·L -1 When, the PAMAM-(DTC) of embodiment 1,2 of the present invention 8 、PAMAM-(DTC) 16 , can meet the emission requirements of "Copper, Cobalt, Nickel Industrial Pollution Source Discharge Standard (GB25467-2010)" and "Urban Comprehensive Sewage Discharge Standard (GB18918-2002)", while the comparison PAMAM-(DTC) 4 is not reached. Comparative example PAMAM-(DTC) 4 Need 250mg·L -1 It can meet the requirements of "Discharge Standards for Copper, Cobalt and Nickel Industrial Pollution Sources (GB25467-2010)", but cannot meet the requirements of "Urban Comprehensive Sewage Discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com