Modified beta-glucosan

A dextran, modification technology, applied in the field of modified β-glucan, can solve the problems that cannot meet the needs of active ingredient embedding, low embedding rate, large particle size, etc., to improve functional value and product quality Properties and consumer acceptance, postprandial blood glucose lowering, solubility and stability enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

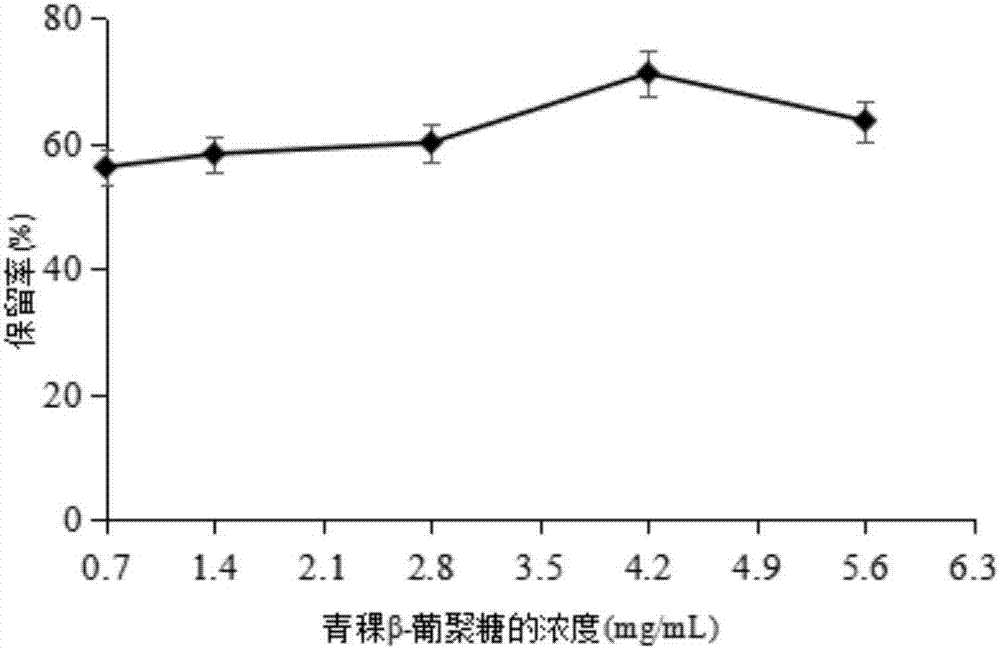

[0033] 1) Disperse 3g of crude barley β-glucan (70%) (equivalent to 2.1g of pure highland barley β-glucan (100%)) in 500mL of pure water, place it in a water bath at 80°C Put in a water bath for 1 hour, and keep stirring to fully dissolve the dextran. After the dissolving process was completed, the highland barley β-glucan aqueous solution was cooled to room temperature and then centrifuged. After the centrifugation, the precipitate was discarded, and the highland barley β-glucan solution was collected for later use.

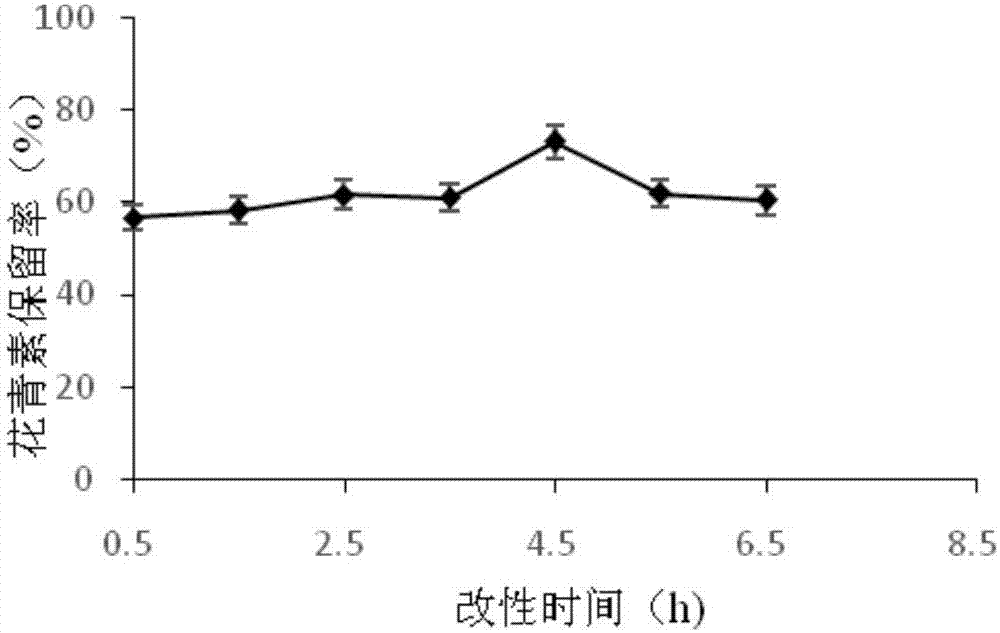

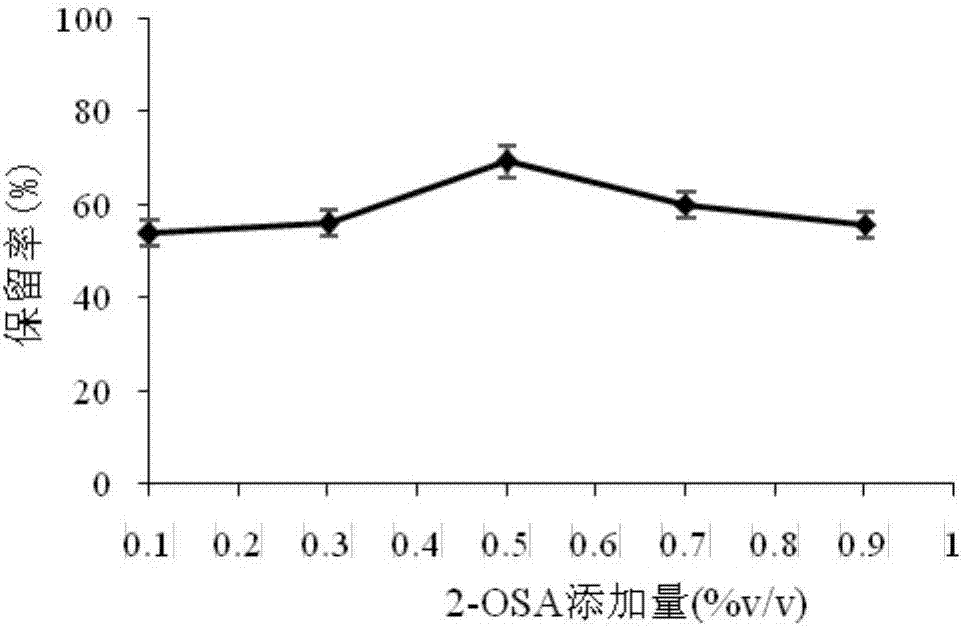

[0034] 2) Then, 0.5 mL of 2-octenyl succinic anhydride (2-OSA) was added dropwise to 100 mL of highland barley β-glucan solution, and reacted at 55 °C for 4.5 h. During the reaction process, 3% (w / v) sodium hydroxide was used to control the pH of the system at about 8.0. After the reaction was completed, the system was cooled to room temperature and continued to stir. Finally, 2 mol / L hydrochloric acid was added dropwise to the reaction system to control the ...

Embodiment 2

[0038] 1) Disperse 300g of highland barley β-glucan crude product (70%) (equivalent to 210g of highland barley β-glucan (100%)) in 50L of pure water, place it in a water bath at 80°C for 1 hour, And keep stirring to fully dissolve the glucan. After the dissolution process is over, cool the highland barley β-glucan aqueous solution to room temperature and then centrifuge. After the centrifugation is completed, discard the precipitate and collect the highland barley β-glucan solution. spare.

[0039]2) Then, 50mL of 2-octenyl succinic anhydride (2-OSA) was added dropwise to 10L of highland barley β-glucan solution, and reacted at 55°C for 4.5h. During the reaction process, 3% (w / v) sodium hydroxide was used to control the pH of the system at about 8.0. After the reaction was completed, the system was cooled to room temperature and continued to stir. Finally, 2 mol / L hydrochloric acid was added dropwise to the reaction system to control the pH of the system at about 6.0, and co...

Embodiment 4

[0049] 1) Add 0.25g of modified highland barley β-glucan into a beaker, add 100mL of distilled water, heat and boil for 2min, replenish the volume to 100mL, continue heating for 1min, and then replenish the volume to 100mL to obtain uniform modified highland barley β-glucan sugar solution.

[0050] 2) Take the modified highland barley β-glucan solution prepared above, add 0.1 g of black wolfberry anthocyanin extract, and stir at 45° C. for 30 min to prepare black wolfberry anthocyanin microcapsule solution.

[0051] 3) Add other auxiliary materials to produce liquid products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com