Chromate-free passivation agent and preparing method and application thereof

A chromium-free passivating agent and passivating agent technology, applied in the coating process of metal materials, etc., can solve the problems that the corrosion resistance cannot achieve the chromate passivation effect, the film formation effect is unstable, and the bonding ability is not strong. , to achieve good passivation effect, good film-forming effect and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] According to another aspect of the present invention, the embodiment of the present invention also provides a method for preparing the above-mentioned chromium-free passivating agent, the method comprising the following steps:

[0068] Heat water to 95-100°C, add fluorozirconate, stir to dissolve, then add fluoride salt, stir evenly to form a mixed solution;

[0069] Add ammonium sulfate, cerium nitrate, sodium nitrate, potassium nitrate, borax, hydrofluoric acid, fluozirconic acid to the mixed solution, stir while adding, and stir for 50-90 minutes after adding all of them to form a passivating agent stock solution;

[0070] The stock solution of the passivating agent is left to stand for 6-9 hours, and then the supernatant liquid is taken out and stored in a precipitation tank for 6-9 hours to obtain a chromium-free passivating agent.

[0071] In the above preparation method, the preparation process of dissolving in boiling water and aging for the second time can shor...

Embodiment 1-5

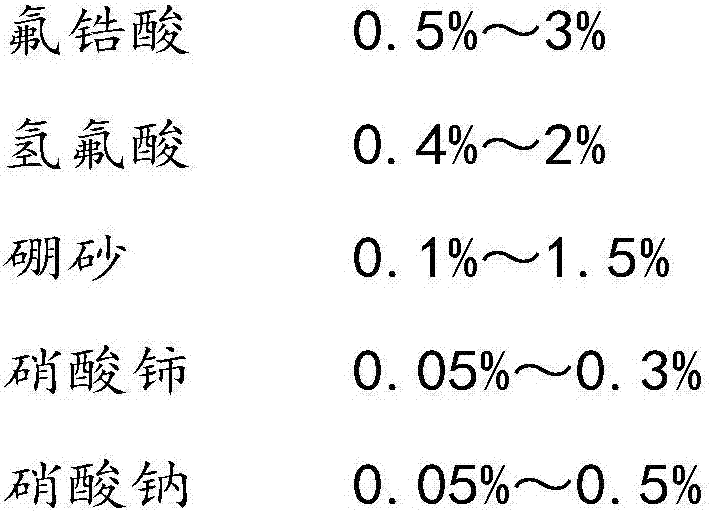

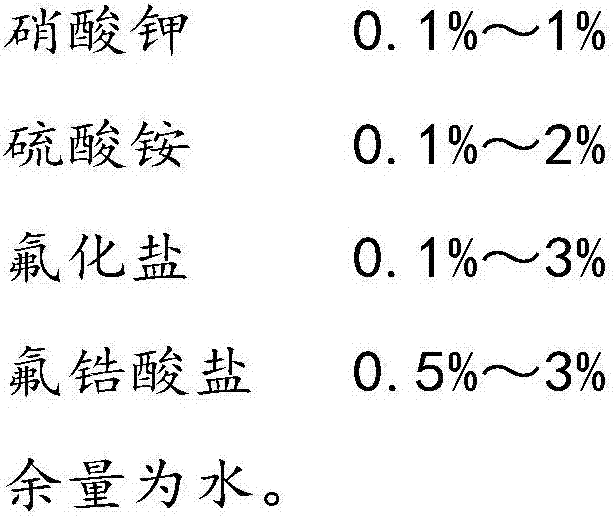

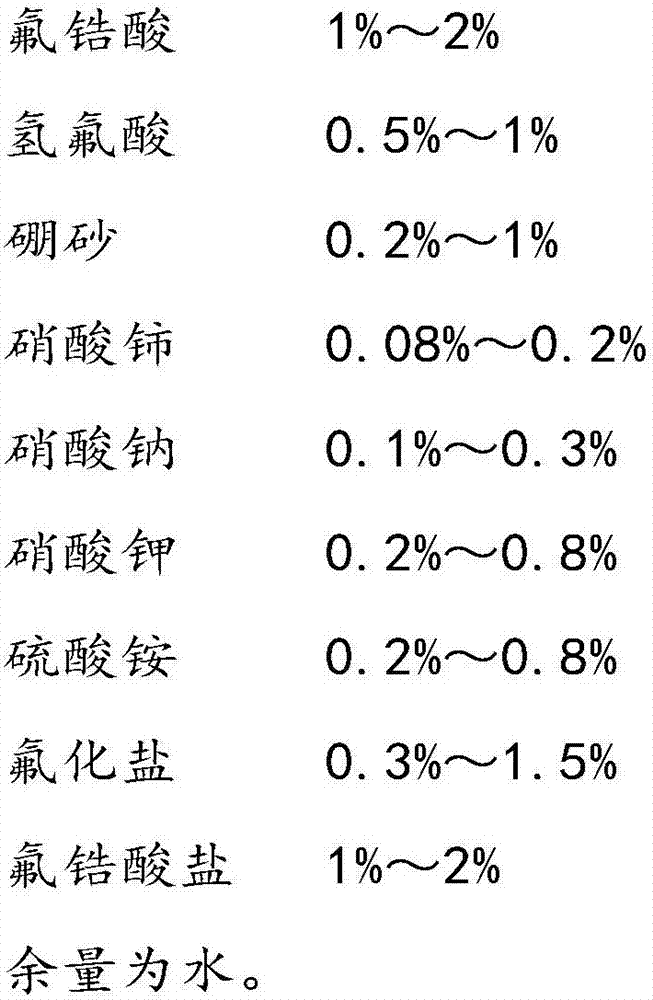

[0089] Chromium-free passivating agent According to the ratio of raw materials shown in Table 1, an appropriate amount of each raw material was weighed, and the rest was distilled water to obtain the chromium-free passivating agent formula of Examples 1-5.

[0090] Table 1 embodiment 1-5 formula of chromium-free passivating agent

[0091] components Example 1 Example 2 Example 3 Example 4 Example 5 Fluorozirconic acid 1.5% 1.6% 0.5% 2% 3% hydrofluoric acid 0.8% 0.9% 0.4% 1% 2% Borax 0.4% 0.5% 0.1% 1% 1.5% Cerium nitrate 0.1% 0.12% 0.08% 0.2% 0.3% sodium nitrate 0.2% 0.25% 0.05% 0.1% 0.5% potassium nitrate 0.3% 0.4% 0.1% 0.8% 1% ammonium sulfate 0.4% 0.5% 0.2% 0.8% 2% sodium fluoride 0.5% 0.6% 0.3% 1.5% 3% Potassium fluozirconate 1.5% 1.6% 0.5% 2% 3%

[0092] Then, prepare chromium-free passivating agent according to the following steps:

[0093] (1) take each raw ma...

experiment example 1

[0098] Adopt the raw material ratio of embodiment 1 to prepare chromium-free passivating agent according to the following method:

[0099] The difference between the steps of its preparation method and that of Example 1 is that the required passivating agent can be obtained without secondary aging. That is, add ammonium sulfate, cerium nitrate, sodium nitrate, potassium nitrate, borax, hydrofluoric acid, and fluozirconic acid to the mixed solution in turn, stir while adding, and stir for 60 minutes after adding all of them to obtain chromium-free passivation. agent.

[0100] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com