IgG-containing fermented milk and preparation method

A technology of immunoglobulin and fermented milk, applied in dairy products, milk preparations, applications, etc., can solve the problems of not containing active immunoglobulin, unable to measure IgG content, unable to retain immunoglobulin, etc., and reach the shelf life Good stability, good flavor, excellent texture and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

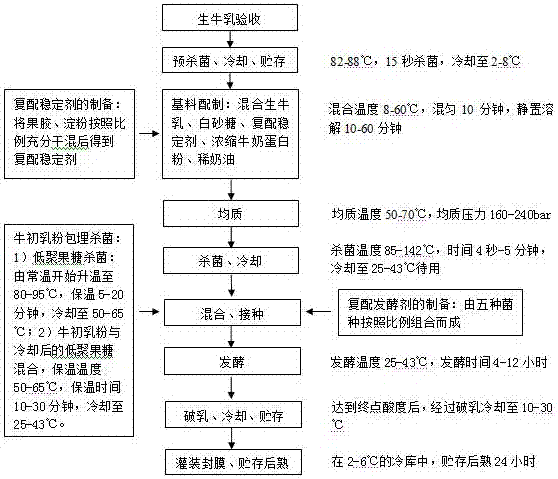

[0040]The preparation method of fermented milk containing active immunoglobulin (IgG) comprises the following steps:

[0041] (1) Raw milk quality control

[0042] Raw milk fat ≥ 3.8% and protein ≥ 3.2% are required for ingredients. The raw milk that passes the inspection is filtered with a filter mesh of more than 80 mesh, pre-sterilized at 82-88°C for 15 seconds, and cooled to 2-8°C for storage. spare;

[0043] (2) Preparation of compound stabilizer

[0044] Among them, the compound stabilizer is prepared from pectin and starch according to the mass percentage of 0.05-0.15% and 0.45%-1.35% of the total formula, and the compound stabilizer is obtained after fully dry mixing the pectin and starch according to the proportion;

[0045] Prepare the fermented milk according to the following steps:

[0046] (3) Preparation of base material

[0047] The base material is the mixture obtained by mixing, homogenizing and sterilizing raw milk, concentrated milk protein powder, cream...

Embodiment 1

[0067] A method for preparing fermented milk containing active immunoglobulin (IgG):

[0068] (1) Raw milk quality control: After the raw milk is accepted, it is filtered, the filter mesh is above 80 mesh, pre-sterilized at 85°C for 15 seconds, cooled to 4°C and stored for later use.

[0069] (2) Preparation of compound stabilizer: fully dry mix 0.05 kg of pectin and 0.45 kg of starch to prepare 0.5 kg of compound stabilizer.

[0070] (3) Base material preparation: Mix 2.4 kg of concentrated milk protein powder, 8 kg of white sugar and 0.5 kg of compound stabilizer evenly, add 81.7 kg of raw milk whose temperature is adjusted to 50°C, and then add 2 Kilogram of cream, stirred and sheared for 10 minutes, mixed evenly and left to dissolve for 30 minutes; adjust the temperature of the mixed base material to 65°C for homogenization, and the homogenization pressure is 180bar. Afterwards, the homogenized base material is sterilized at a temperature of 95° C. for 5 minutes, and cool...

Embodiment 2

[0076] A method for preparing fermented milk containing active immunoglobulin (IgG):

[0077] (1) Raw milk quality control: After the raw milk is accepted, it is filtered with a filter mesh of more than 80 meshes, pre-sterilized at 85°C for 15 seconds, cooled to 6°C and stored for later use.

[0078] (2) Preparation of compound stabilizer: 0.08 kg of pectin and 0.72 kg of starch were fully dry mixed to prepare 0.8 kg of compound stabilizer.

[0079] (3) Base material preparation: Mix 2.4 kg of concentrated milk protein powder, 8 kg of white sugar and 0.8 kg of compound stabilizer evenly, add 81.4 kg of raw milk whose temperature is adjusted to 45°C, and then add 2 One kilogram of cream was stirred and sheared for 10 minutes, mixed evenly and left to dissolve for 30 minutes. Adjust the temperature of the mixed base material to 63° C. for homogenization, and the homogenization pressure is 200 bar. Afterwards, the homogenized base material is sterilized at a temperature of 90° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com