Synthesis and application methods for non-noble metal catalyst used for selective hydrogenation of high concentration acetylene to produce ethylene

A non-precious metal, selective hydrogenation technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A non-precious metal catalyst for selective hydrogenation of high-concentration acetylene to ethylene. Its active components are Ni, Zn and K, and its carrier is α-Al 2 O 3 , And use DFM as the solvent and graphene as the intensifier to synthesize under non-aqueous conditions. After calcination, it is reduced in a hydrogen atmosphere.

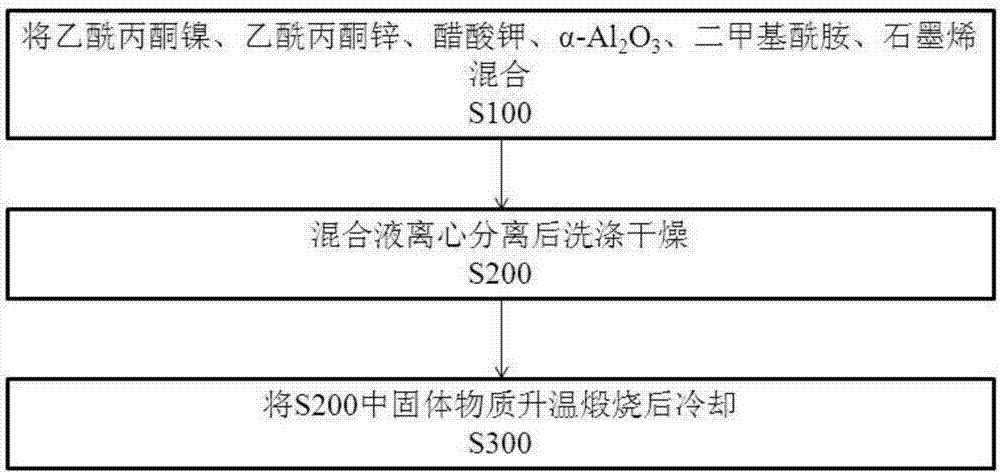

[0029] In the preparation method of the non-precious metal catalyst in this embodiment, the specific steps are as follows:

[0030] At step (1) shown in box S100, weigh or measure 10.5g nickel acetylacetonate, 31.5g zinc acetylacetonate, 5.4g potassium acetate, and α-Al according to the catalyst synthesis ratio. 2 O 3 100g, 120ml of DFM and 20g of graphene are immersed in a reactor equipped with a stirring and heating device, the temperature is controlled at 100°C, normal pressure, and stirring is performed for 8 hours.

[0031] At step (2) shown in block S200, the above-mentioned mixed liquid is centrifuged, and the solid material is washed wit...

Embodiment 2

[0035] A non-precious metal catalyst for selective hydrogenation of high-concentration acetylene to ethylene. Its active components are Ni, Zn and K, and its carrier is α-Al 2 O 3 , And use DFM as the solvent and graphene as the intensifier to synthesize under non-aqueous conditions. After calcination, it is reduced in a hydrogen atmosphere.

[0036] In the preparation method of the non-precious metal catalyst in this embodiment, the specific steps are as follows:

[0037] At step (1) shown in box S100, weigh 8.7g nickel acetylacetonate, 20g zinc acetylacetonate, 2.5g potassium acetate, and α-Al according to the catalyst synthesis ratio. 2 O 3 100g, DFM100ml, and graphene 20g are immersed in a reactor equipped with a stirring and heating device, the temperature is controlled at 70°C, normal pressure, and stirred for 10 hours.

[0038] At step (2) shown in block S200, the above-mentioned mixed liquid is centrifuged, and the solid material is washed with absolute ethanol for 2 to 3 time...

Embodiment 3

[0042] A non-precious metal catalyst for selective hydrogenation of high-concentration acetylene to ethylene. Its active components are Ni, Zn and K, and its carrier is α-Al 2 O 3 , And use DFM as the solvent and graphene as the intensifier to synthesize under non-aqueous conditions. After calcination, it is reduced in a hydrogen atmosphere.

[0043] In the preparation method of the non-precious metal catalyst in this embodiment, the specific steps are as follows:

[0044] At step (1) shown in box S100, according to the catalyst synthesis ratio, weigh 30g nickel acetylacetonate, 40g zinc acetylacetonate, 7.5g potassium acetate, and α-Al 2 O 3 100g, DFM150ml, graphene 30g, impregnated in a reactor equipped with a stirring and heating device, the temperature is controlled at 100℃, normal pressure, stirring for 15h;

[0045] At step (2) shown in block S200, the above-mentioned mixed liquid is centrifuged, and the solid material is washed with absolute ethanol for 2 to 3 times, filtered, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com