Method for preparing nitrogen-doped molybdenum disulfide nanosheets by one-step method

A molybdenum disulfide, nitrogen doping technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of reducing specific surface area, complex process, limiting performance, etc., and achieve simple and fast operation. , low reaction temperature, good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing nitrogen-doped molybdenum disulfide nanosheets in one step, comprising the following steps:

[0025] (1) Take by weighing 1.236 grams of ammonium molybdate tetrahydrate, 2.284 grams of thiourea and 0.843 grams of urotropine, and disperse them in 40 milliliters of deionized water, under the action of ultrasonic and magnetic stirring, make it fully Disperse and dissolve.

[0026] (2) Transfer the above-prepared sample to a 50 ml reaction kettle, tighten the reaction kettle, place it in a blast drying oven at 220°C for 24 hours, and cool it down to room temperature naturally after the reaction is over.

[0027] (3) The black precipitate product generated after the reaction was taken out, washed with deionized water and absolute ethanol several times, and the sample was collected by centrifugation to obtain a solid powder.

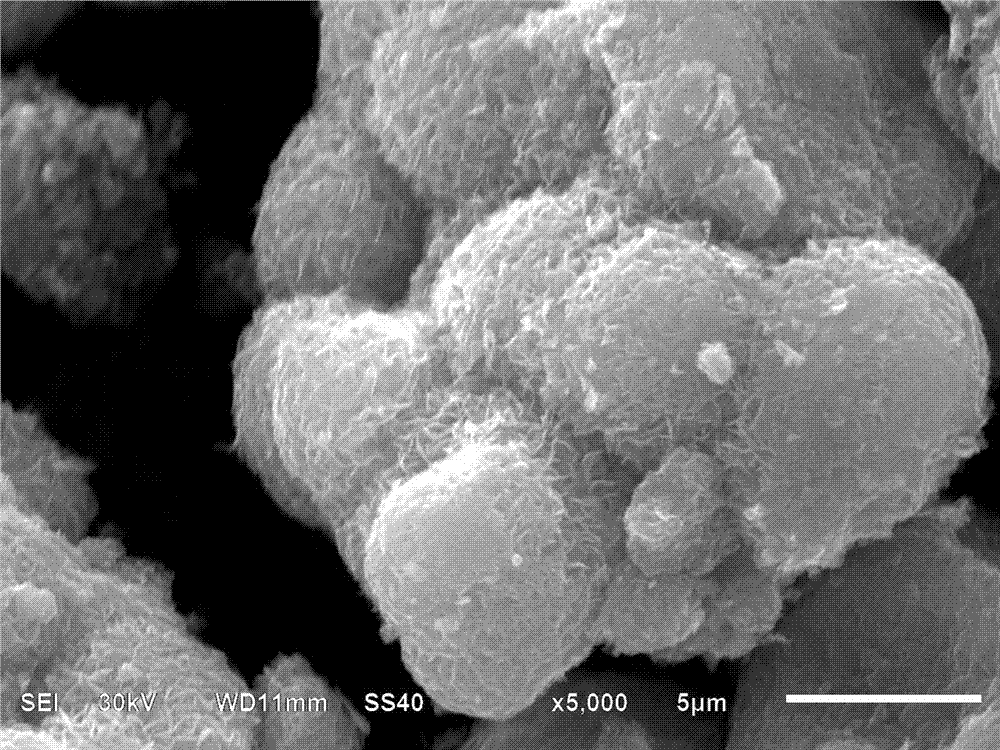

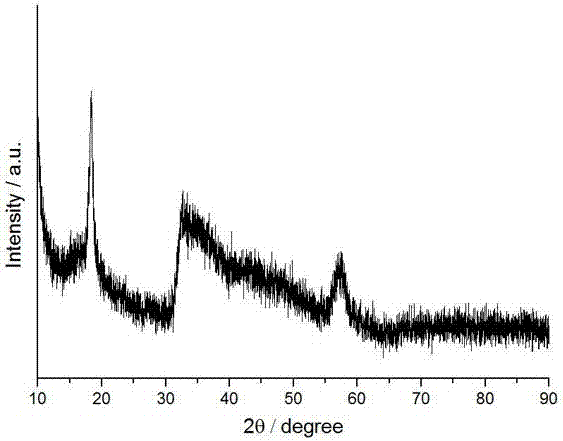

[0028] (4) Dry the above black solid powder in a vacuum oven at 60°C to constant weight for later use. The morphology and phas...

Embodiment 2

[0035] One-step method for preparing nitrogen-doped molybdenum disulfide nanosheets, the steps are as follows:

[0036] 1. Take a certain amount of ammonium molybdate tetrahydrate, thiourea and urotropine, and disperse them in a container with deionized water, and fully dissolve and disperse them under the action of ultrasonic and magnetic stirring;

[0037] 2. Transfer the solution obtained in step 1 to a polytetrafluoroethylene-lined reaction kettle, place it in a blast drying oven and heat it for a chemical reaction. After a period of reaction, stop heating and allow the reaction kettle to cool naturally to room temperature;

[0038] 3. After cooling to room temperature, centrifuge the reacted solution, collect the synthesized black substance, and wash it several times with a mixed solution of deionized water and absolute ethanol;

[0039] 4. Place the powder obtained after washing in step 3 in a vacuum drying oven and vacuum dry to constant weight.

[0040] The mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com