Method and device for producing polyolefin through dynamical operation

A technology of dynamic operation and polyolefin, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low cost and high catalyst requirements, achieve easy operation, simple process flow, reduce equipment investment costs and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

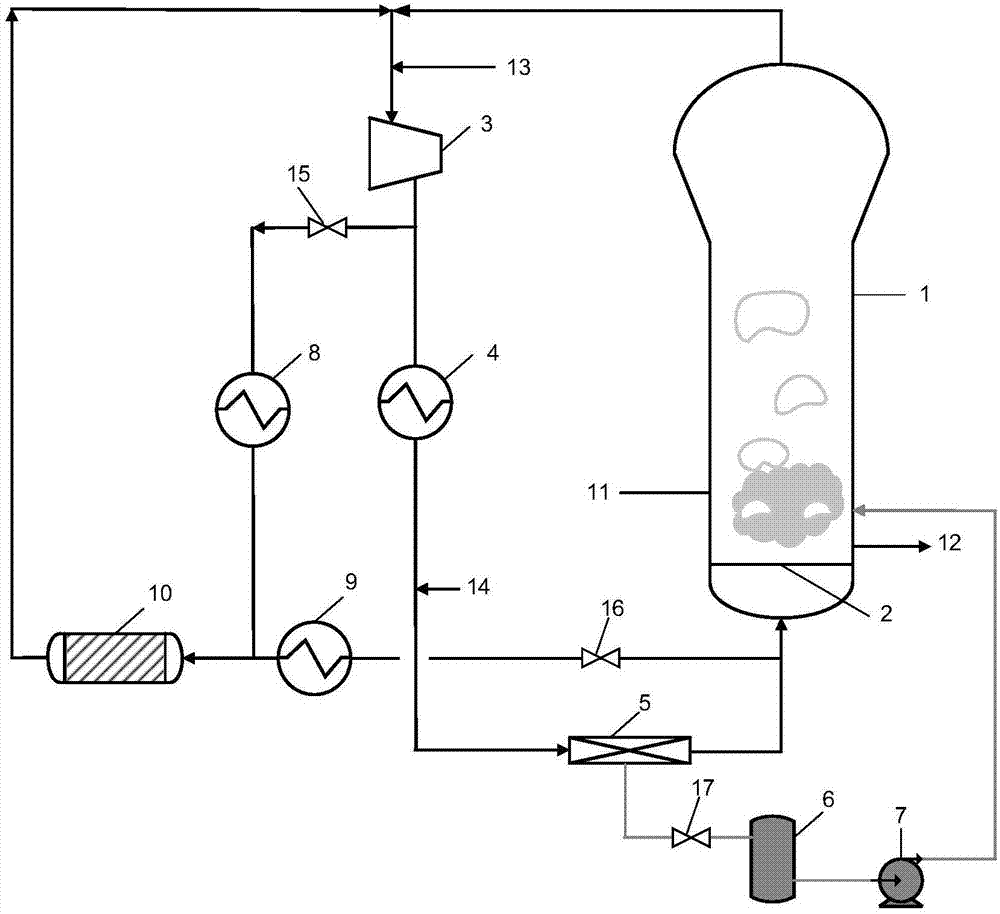

[0075] exist figure 1 The broad-peak polyethylene of an olefin polymerization method shown, ethylene, 1-butene, hydrogen, nitrogen, isopentane, high-activity titanium catalyst, TEAL cocatalyst are introduced into fluidized bed reactor 1, and the polymerization reaction temperature is 80 ℃, pressure 2.1MPa, fluidized bed reactor 1 maintains a dense-phase bed state, the circulating material enters at the bottom of the fluidized bed reactor, the superficial velocity of the gas material is 0.60m / s, and the polyethylene powder in fluidized bed 1 is maintained of fluidization. The hydrogen absorption tower 10 is filled with a lanthanum-nickel hydrogen storage alloy. The time ratio between the first production stage and the second production stage is 8:2. In the first production stage, a stream of gas is drawn from the circulation loop between the gas-liquid separator 5 and the fluidized bed reactor 1, and enters the hydrogen absorption tower 10 after exchanging heat with the third...

Embodiment 2

[0078] exist figure 1A broad-peak polyethylene in the olefin polymerization method shown, ethylene, 1-butene, hydrogen, nitrogen, n-hexane, highly active titanium catalyst, and TEAL cocatalyst are introduced into fluidized bed reactor 1, and the polymerization reaction temperature is 90°C , the pressure is 2.5MPa, the fluidized bed reactor 1 maintains a dense phase bed state, the circulating material enters at the bottom of the fluidized bed reactor, the superficial velocity of the gaseous material is 0.65m / s, and the polyethylene powder in the fluidized bed 1 is maintained Fluidize. The hydrogen absorption tower 10 is filled with a lanthanum-nickel hydrogen storage alloy. The time ratio between the first production stage and the second production stage is 8:2. In the first production stage, a stream of gas is drawn from the circulation loop between the gas-liquid separator 5 and the fluidized bed reactor 1, and enters the hydrogen absorption tower 10 after exchanging heat w...

Embodiment 3

[0081] exist figure 1 A broad-peak polyethylene in the olefin polymerization method shown, ethylene, 1-hexene, hydrogen, nitrogen, isopentane, highly active titanium catalyst, and TEAL cocatalyst are introduced into fluidized bed reactor 1, and the polymerization reaction temperature is 85 ℃, pressure 2.1MPa, fluidized bed reactor 1 maintains a dense-phase bed state, the circulating material enters at the bottom of the fluidized bed reactor, the superficial velocity of the gas material is 0.68m / s, and the polyethylene powder in fluidized bed 1 is maintained of fluidization. The hydrogen absorption tower 10 is filled with a lanthanum-nickel hydrogen storage alloy. The time ratio between the first production stage and the second production stage is 8:2. In the first production stage, a stream of gas is drawn from the circulation loop between the gas-liquid separator 5 and the fluidized bed reactor 1, and enters the hydrogen absorption tower 10 after exchanging heat with the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com