Biodegradable microorganism sustained-release agent as well as preparation method and application thereof

A biodegradable and microbial technology, applied in the field of microbial sustained-release agents, can solve the problems of inferior physiological adaptability of strains, high frequency and amount of bacterial injection, and inability to grow dominant bacterial groups, etc., to achieve significant sustained-release effect, High embedding rate, avoiding the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

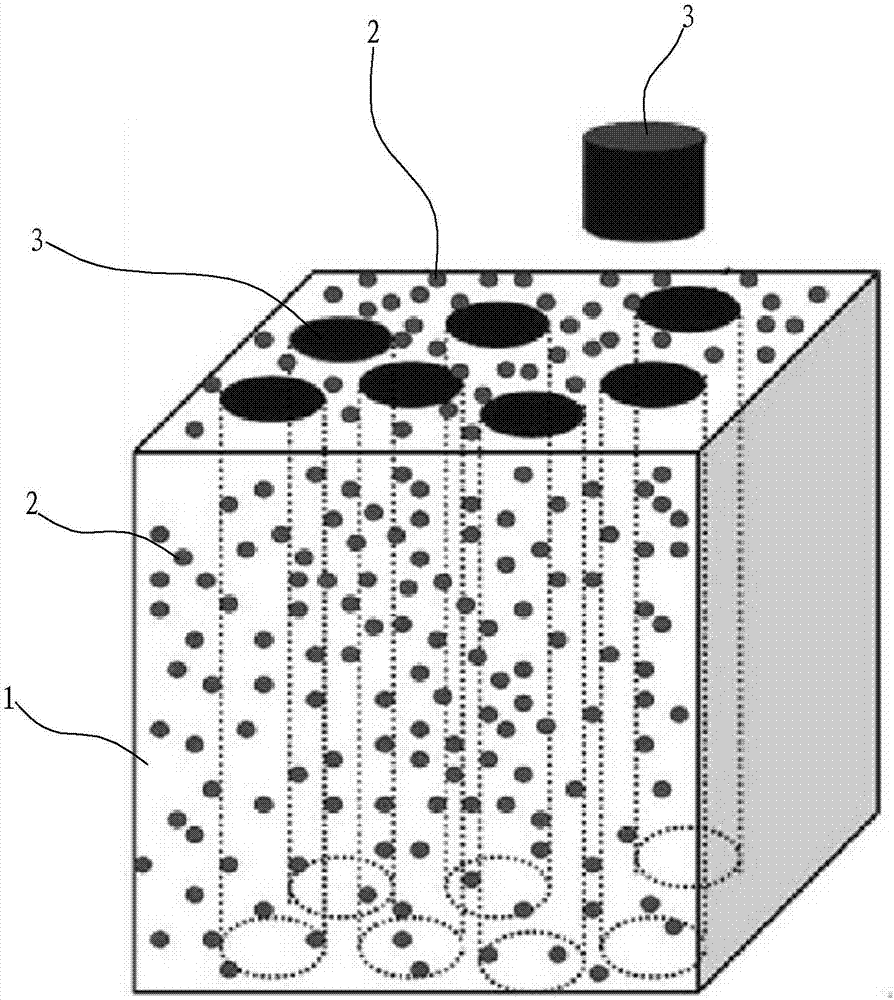

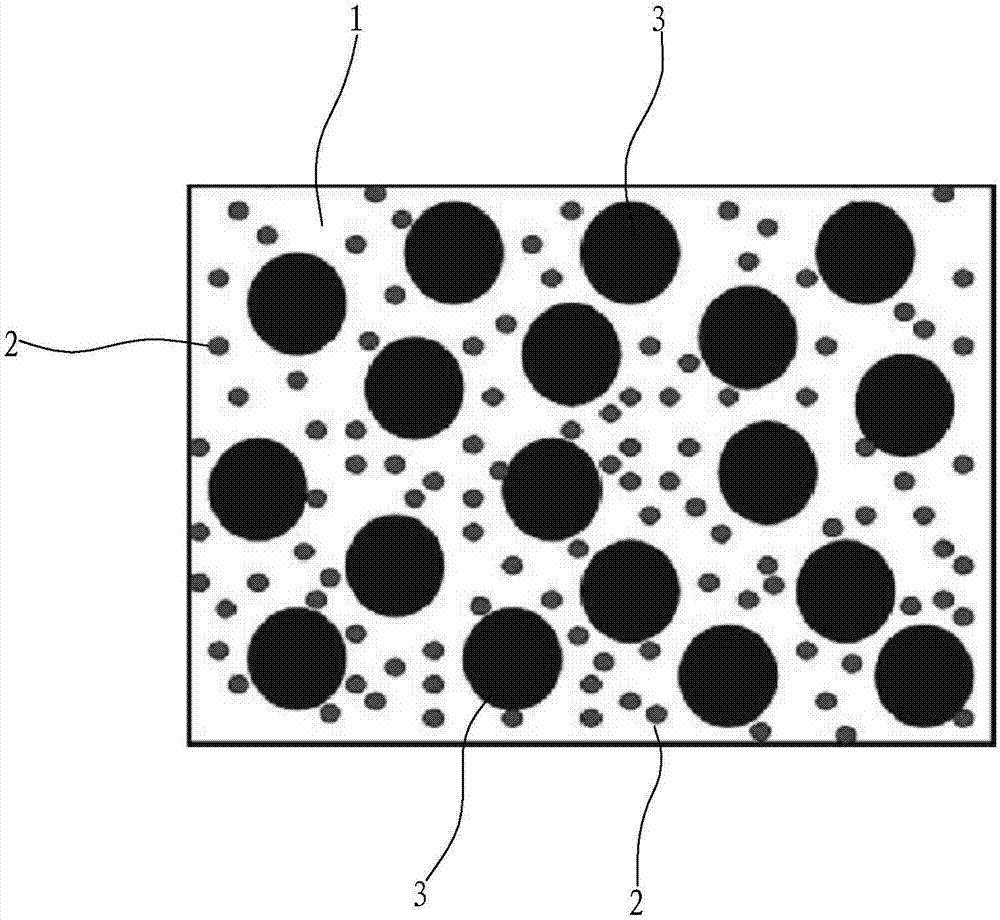

[0031] (1) Preparation of carbon source slow-release body: 20g sodium citrate, 10g sodium acetate, 20g polylactic acid, 30g polystyrene and 20g cod gum (food grade, Shandong Zhongke Biotechnology Co., Ltd.) were evenly mixed to obtain mixture. Then put the mixture into the barrel of the injection molding machine, and the injection molding temperature is 140° C. After one injection molding, the carbon source slow-release body is obtained after natural cooling at room temperature.

[0032] (2) Preparation of hydrogel bacterial agent carrier containing bacterial powder: Dissolve γ-polyglutamic acid in deionized water to prepare 200 mL aqueous solution of γ-polyglutamic acid (γ-PGA) with a concentration of 100 mg / mL , the temperature was adjusted to 40°C, and stirred at constant temperature for 10 hours to fully swell and dissolve. Then the γ-polyglutamic acid solution is placed in a three-necked flask, a mixture of 1.5g of ethylene glycol glycidyl ether / pentaerythritol and bacte...

Embodiment 2

[0040] (1) Preparation of carbon source slow-release body: 30 g of sodium citrate, 20 g of sodium acetate, 20 g of polylactic acid, 10 g of polystyrene and 5 g of cod gum were evenly mixed to obtain a mixture. Then put the mixture into the cylinder of the injection molding machine, the injection molding temperature is 160°C, after one injection molding, the carbon source slow-release body is obtained after natural cooling at room temperature.

[0041] (2) Preparation of bacteria powder-containing hydrogel bacterial agent carrier: Dissolve γ-polyglutamic acid in deionized water to prepare 200 mL aqueous solution of γ-polyglutamic acid with a concentration of 200 mg / mL, and adjust the temperature at 50 ℃, stirring at constant temperature for 14 hours to make it fully swell and dissolve. Then the γ-polyglutamic acid solution is placed in a three-necked flask, a mixture of 3.0g of ethylene glycol glycidyl ether / pentaerythritol and bacterium powder of 1.0g are added, and in the mix...

Embodiment 3

[0046] (1) Preparation of carbon source slow-release body: 36.0 g of sodium citrate, 27.0 g of sodium acetate, 30.0 g of polylactic acid, 5 g of polystyrene and 5 g of curd gum were uniformly mixed to obtain a mixture. Then put the mixture into the cylinder of the injection molding machine, and the injection molding temperature is 180° C. After one injection molding, the carbon source slow-release body is obtained after natural cooling at room temperature.

[0047] (2) Preparation of hydrogel bacterial agent carrier containing bacterial powder: Dissolve γ-polyglutamic acid in deionized water to prepare 200 mL aqueous solution of γ-polyglutamic acid with a concentration of 400 mg / mL, and adjust the temperature to 60 ℃, stirring at constant temperature for 16 hours to make it fully swell and dissolve. Then the γ-polyglutamic acid solution is placed in a three-necked flask, a mixture of 5.0 g of ethylene glycol glycidyl ether / pentaerythritol and 2.0 g of bacteria powder are added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total viable bacteria | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com