Practical environmental fully-degradable material and method for preparing same

A technology for fully degrading and degrading plastics, applied in the field of practical environmental fully degradable materials and their preparation, can solve the problems of residual film pollution, blocked root growth of crops, and reduced yield, so as to eliminate different degradation rates and improve the emergence rate of crops. , Excellent temperature and moisture retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

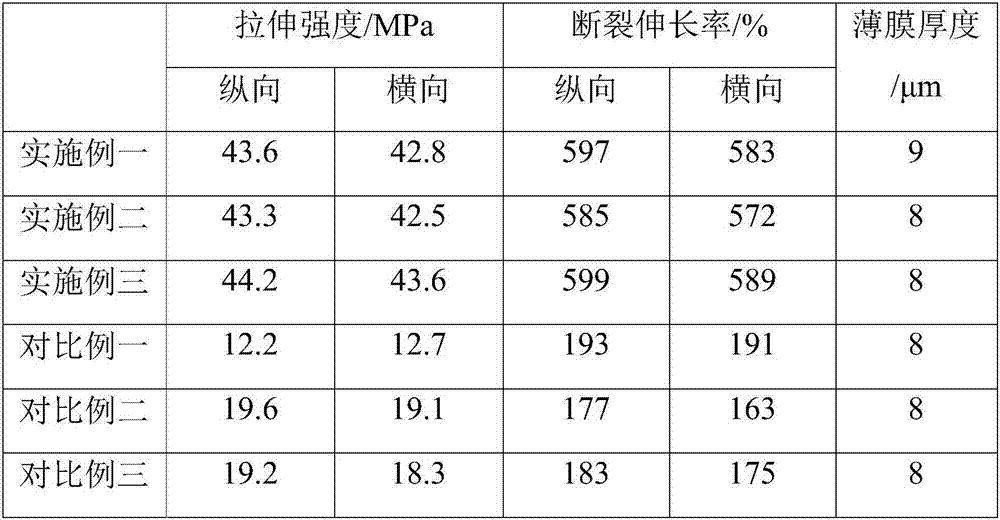

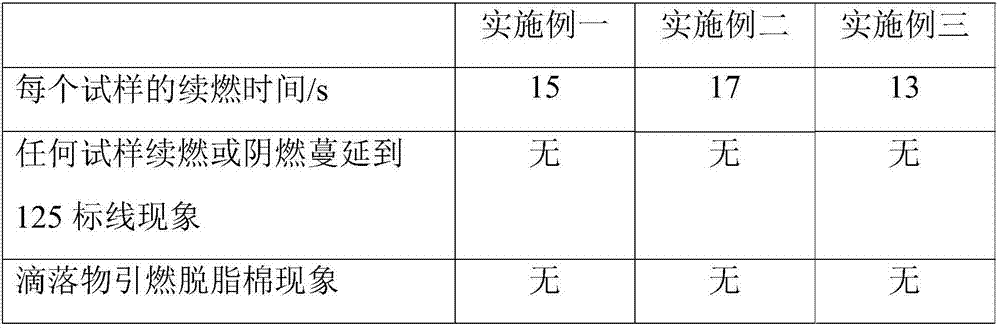

Embodiment 1

[0037] The invention provides a fully degradable material. The fully degradable material adopts a double-layer film structure, including a first layer of film and a second layer of film, and the degradation time of the first layer of film is longer than that of the second layer of film; wherein, the first The raw material components of the film include: 32 parts by weight of high-density polyethylene CH2802, 20 parts by weight of low-density polyethylene LD662, 8 parts by weight of polylactic acid with a number average molecular weight of 50000, 5 parts by weight of lanthanum oxide, chlorine 1 part by weight of europium chloride, 5 parts by weight of yttrium nitrate, 0.05 parts by weight of zinc laurate, 0.03 parts by weight of 2,6-di-tert-butyl-p-cresol, 0.01 parts by weight of diatomaceous earth, 0.07 parts by weight of humic acid and number average 5 parts by weight of polyethylacrylate with a molecular weight of 10000; the raw material components of the second layer of film...

Embodiment 2

[0043] The invention provides a fully degradable material. The fully degradable material adopts a double-layer film structure, including a first layer of film and a second layer of film, and the degradation time of the first layer of film is longer than that of the second layer of film; wherein, the first The raw material components of the film include: 42 parts by weight of high-density polyethylene 5502, 15 parts by weight of low-density polyethylene 2426H, 15 parts by weight of polylactic acid with a number average molecular weight of 100000, 3 parts by weight of lanthanum oxide, chlorine 3 parts by weight of europium chloride, 2 parts by weight of yttrium nitrate, 0.10 parts by weight of zinc laurate, 0.01 parts by weight of 2,6-di-tert-butyl-p-cresol, 0.05 parts by weight of diatomaceous earth, 0.03 parts by weight of humic acid and the number average 8 parts by weight of polyethyl acrylate with a molecular weight of 8,000; the raw material components of the second layer o...

Embodiment 3

[0049] The invention provides a fully degradable material. The fully degradable material adopts a double-layer film structure, including a first layer of film and a second layer of film, and the degradation time of the first layer of film is longer than that of the second layer of film; wherein, the first The raw material components of the film include: 36 parts by weight of high-density polyethylene 6070, 18 parts by weight of low-density polyethylene 2436H, 10 parts by weight of polylactic acid with a number average molecular weight of 20000, 4 parts by weight of lanthanum oxide, chlorine 2 parts by weight of europium chloride, 3 parts by weight of yttrium nitrate, 0.08 parts by weight of zinc laurate, 0.02 parts by weight of 2,6-di-tert-butyl-p-cresol, 0.03 parts by weight of diatomaceous earth, 0.05 parts by weight of humic acid and number average 6 parts by weight of polyethyl acrylate with a molecular weight of 20,000; the raw material components of the second layer of fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com