Method for extracting high-purity alumina from pulverized fuel ash of pulverized coal furnace

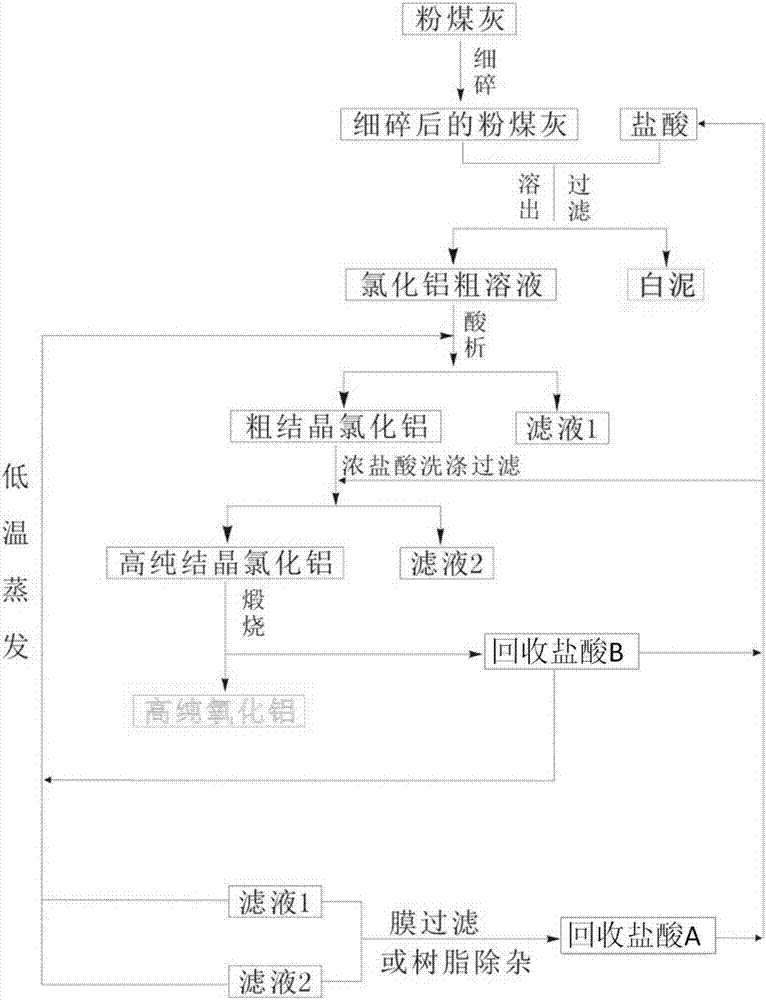

A high-purity alumina and fly ash technology, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of low alumina and white mud extraction rate, large amount of residue, complex process, etc. Equipment investment, high purity, simple activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] (1) Mix 1200:1 fly ash with polypropylene alcohol dispersant and grind to below 2μm

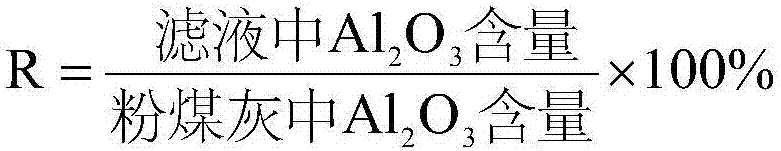

[0062] (2) the pulverized coal ash and 30% hydrochloric acid in the step (1) are mixed evenly by the solid-to-liquid ratio of 1:12 by the fly ash quality (g) and the hydrochloric acid volume (ml) ratio, in airtight stirring Under the conditions, leaching at 160°C for 2 hours, filtering, analyzing and testing the filtrate, the dissolution rate of alumina is 95%.

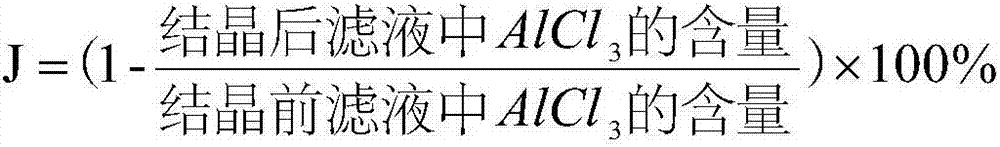

[0063] (3) feed hydrogen chloride gas to the thick aluminum chloride solution gained in step (2) to supersaturation, control the temperature to be no more than 50° C., filter to obtain thick crystallized aluminum chloride, and the crystallization rate is above 99%; The crystalline aluminum chloride is washed 3 times to obtain high-purity crystalline aluminum chloride; the filtrate and washing liquid in this process are evaporated at low temperature to prepare hydrogen chloride gas, which is reused in step (3).

[0064] (4) Ca...

example 2

[0067] (1) Grinding the fly ash below 4 μm;

[0068] (2) The pulverized coal ash of step (1) and 25% hydrochloric acid are mixed evenly at a solid-to-liquid ratio of 1:10 by the fly ash mass (g) and hydrochloric acid volume (ml) ratio, and the leaching at 140°C for 1 hour, filtered, and the filtrate was analyzed and tested, and the dissolution rate of alumina was 88%;

[0069] (3) After evaporating the crude aluminum chloride solution obtained in step (2) to supersaturation, feed hydrogen chloride gas to supersaturation, control the temperature not to exceed 50°C, and filter to obtain coarse crystalline aluminum chloride, the crystallization rate of aluminum chloride More than 99.10%; the crystalline aluminum chloride is washed twice with concentrated hydrochloric acid to obtain high-purity crystalline aluminum chloride.

[0070] (4) Roasting the high-purity crystalline aluminum chloride obtained in step (3) at a temperature of 1000°C for 2 hours to obtain the product high-pu...

example 3

[0074] (1) Grind the fly ash to 2 μm or less.

[0075] (2) The pulverized coal ash of step (1) and 30% hydrochloric acid are mixed uniformly at a solid-to-liquid ratio of 1:10 by the fly ash mass (g) and hydrochloric acid volume (ml) ratio, and the condition of airtight stirring leaching at 170°C for 2 hours, filtered, and the filtrate was analyzed and tested, and the dissolution rate of alumina was 99%.

[0076] (3) Pass into hydrogen chloride gas to the aluminum chloride solution gained in step (2), control the temperature not to exceed 50°C, control the acidity of the solution at 8mol / l, filter to obtain a part of high-purity crystalline aluminum chloride, and the crystallization rate is 65%. Continue to feed hydrogen chloride gas into the filtrate until it is supersaturated, filter the obtained crude crystalline aluminum chloride, wash the above-mentioned crude crystalline aluminum chloride 3 times with concentrated hydrochloric acid, and obtain another part of high-purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap