Oxidation treatment method for leachate biological treatment effluent

A treatment method and oxidant technology, applied in the direction of contaminated groundwater/leachate treatment, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of acid and alkali consumption, secondary pollution, large amounts of chemical sludge, etc. Achieve the effect of reducing treatment cost, good oxidation effect and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

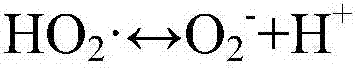

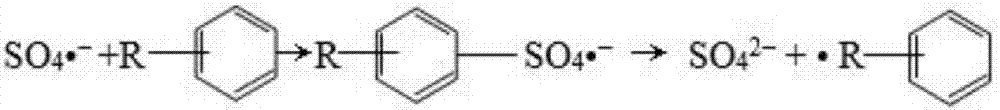

Method used

Image

Examples

preparation example Construction

[0069] Wherein the preparation method of hydrotalcite-like catalyst comprises the steps:

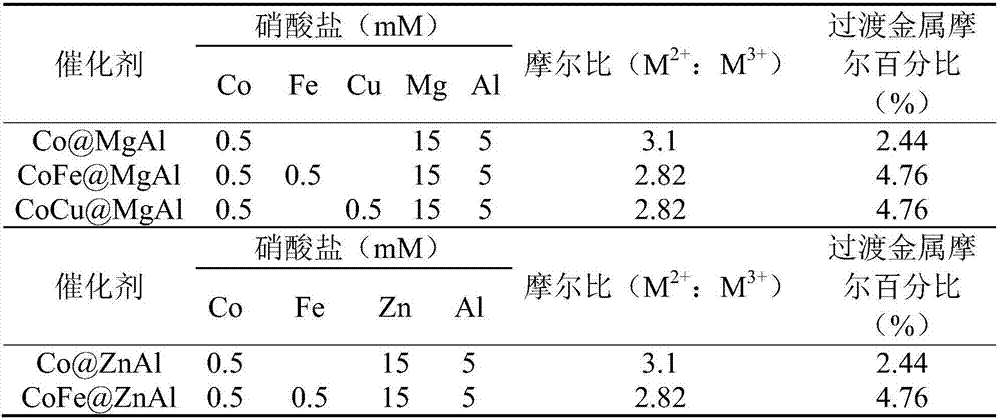

[0070] (1) Prepare solution A: prepare one or more nitrate, magnesium nitrate and aluminum nitrate solutions in transition metal Co, Fe and Cu, obtain solution A after mixing, wherein the molar concentration ratio of magnesium nitrate and aluminum nitrate is 2~4:1; the mole percentage of the transition metal is 1%~5%;

[0071] (2) Prepare solution B: prepare a 0.3mol / L sodium carbonate solution to obtain solution B;

[0072] (3) Co-precipitation of solution A and solution B: add solution A described in step (1) dropwise to solution B described in step (2) at a speed of 100 to 150 ml / h to carry out coprecipitation reaction. Then continue to stir for 1-1.5 hours, and then conduct ultrasound to obtain a mixed solution, which is left to stand for 18-24 hours to obtain a co-precipitation system;

[0073] (4) Obtaining the hydrotalcite-like catalyst: the co-precipitation system described in ...

Embodiment 1

[0080] The method of heterogeneous catalytic oxidation of the present invention is used to treat the COD of the effluent of the domestic garbage leachate MBR system, wherein the catalysts are selected from five different catalysts prepared by the preparation method of the present invention, namely CoFe@MgAl, CoCu@MgAl, Co @MgAl, Co@ZnAl and CoFe@ZnAl, the oxidant is H 2 o 2 and PMS to form a double oxidant.

[0081] Taking CoFe@MgAl as an example, its preparation method includes the following steps:

[0082] (1) Prepare solution A: prepare nitrate, magnesium nitrate and aluminum nitrate of transition metal Co and Fe, and obtain solution A after mixing, wherein the molar concentration ratio of magnesium nitrate and aluminum nitrate is 3:1; transition metal Co and Fe The molar ratio is 4.76% (the sum of the molar weights of Co and Fe accounts for the molar percentage of all metal molar weights);

[0083] (2) Prepare solution B: prepare a 0.3mol / L sodium carbonate solution to ...

Embodiment 2

[0094] The COD of the domestic waste leachate MBR system treated water is treated by using the heterogeneous catalytic oxidation method of the present invention. The catalyst is the LDH catalyst with the prepared CoFe@MgAl structure, and the characteristics of the leachate are shown in Table 3.

[0095] Table 3 Leachate MBR effluent characteristics

[0096]

[0097] Put 10mL leachate MBR system treated effluent into 20mL reaction device, add corresponding catalyst and oxidant, and the reaction time is 3 hours.

[0098] Reaction 1: Catalyst 1g / L+H 2 o 2 Dosage 0.5mol / L; (single H 2 o 2 )

[0099] Reaction 2: catalyst 1g / L + potassium persulfate compound salt dosage 5g / L; (single PMS, PMS2.35g / L)

[0100] Reaction 3: H 2 o 2 Dosage 0.5mol / L+potassium persulfate compound salt dosage 5g / L; (without catalyst, PMS 2.35g / L)

[0101] Reaction 4: Catalyst 1g / L+H 2 o 2 Dosage 0.5mol / L + potassium persulfate compound salt dosage 5g / L; (double oxidant, of which PMS 2.35g / L) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com