Solid-phase denitrification coupling carrier for simultaneous denitrification and carbon removal

A nitrification coupling and carrier technology, applied in the field of solid phase nitrification, can solve the problems of complex dosing equipment, increase of effluent organic matter content and chroma, and slow release of solid carbon source, so as to increase the enriched microbial biomass and reduce effluent organic matter Content, denitrification performance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0029] Embodiment 1-7: adopt the same agricultural runoff water quality to configure influent (wherein organic matter concentration 20.74mg / L, nitrate nitrogen 6.22mg / L, ammonia nitrogen 7.11mg / L, nitrite nitrogen 5.84mg / L), influent pH and temperature 7.0~8.0 and 25±2°C respectively, and set the hydraulic retention time to 6h.

[0030] The determination of ammonia nitrogen is determined by Nessler's reagent colorimetry after distillation; the determination of nitrate nitrogen is determined by phenol disulfonic acid ultraviolet spectrophotometry; the determination of nitrite nitrogen is determined by diazo coupling spectrophotometry; the concentration of organic matter is determined by dichromic acid Determination of potassium method. The above-mentioned determination method refers to the second editorial office of China Standard Press. Water affairs management-a complete book of laws, standards and norms: water source environment volume [M]. Beijing: China Standard Press, 200...

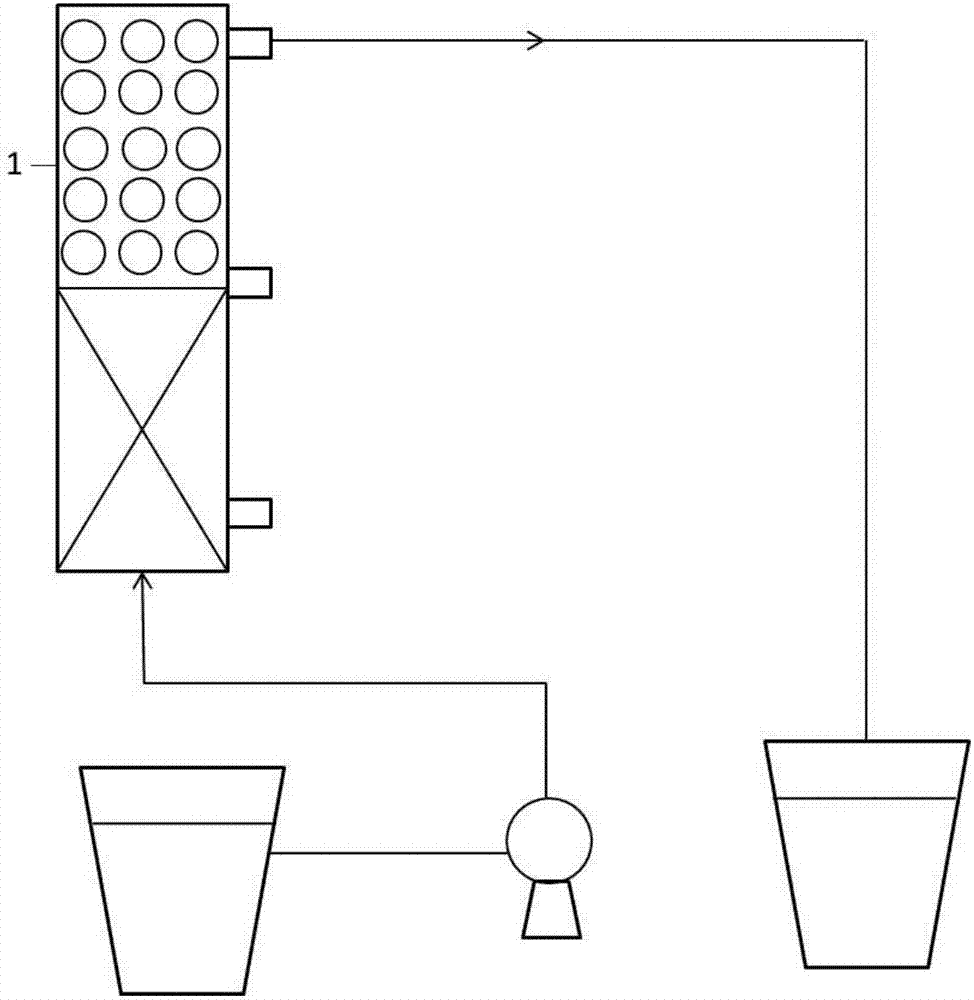

Embodiment 1

[0032] The experiment uses a continuous flow bioreactor, made of plexiglass, with an effective volume of 4L. Select the suspended filler as the PBS carrier, and the density ρ of the suspended filler is 0.96g / cm 3 , the specific surface area is about 500m 2 / m 3 . Choose corncobs as biodegradable carriers, wash and dry the corncobs, and cut the corncobs into 1cm 3 Size, divided into mesh bags (7cm×9cm), each bag is 5g. Take 50.0g of corncobs and 50g of PBS carriers, and fill them in the following way: suspending the filler before filling, that is, filling the PBS carrier in the area near the water inlet of the reactor, and filling the area of the reactor near the water outlet with corncobs. The concentration of three-state nitrogen (nitrate nitrogen, ammonia nitrogen, and nitrite nitrogen) and organic matter (total organic carbon) in the influent and effluent water was regularly measured, and the removal rates of nitrate nitrogen, ammonia nitrogen, nitrite nitrogen, and o...

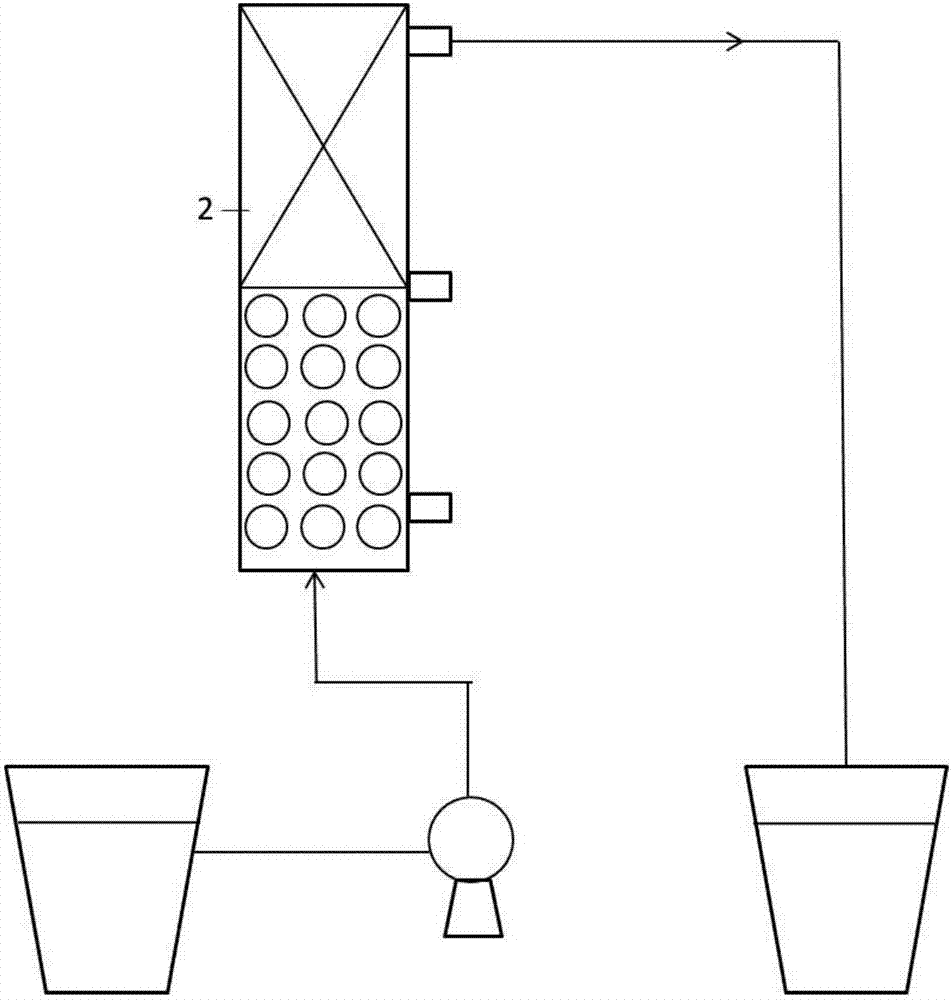

Embodiment 2

[0036] The experiment uses a continuous flow bioreactor, made of plexiglass, with an effective volume of 4L. Select the suspended filler as the PBS carrier, and the density ρ of the suspended filler is 0.96g / cm 3 , the specific surface area is about 500m 2 / m 3 . Choose corncobs as biodegradable carriers, wash and dry the corncobs, and cut the corncobs into 1cm 3Size, divided into mesh bags (7cm×9cm), each bag is 5g. Take 50.0g of corn cob and 50g of PBS carrier, the filling method is: the biodegradable carrier is placed in front, that is, the corn cob is filled in the area near the water inlet of the reactor, and the PBS carrier is filled in the area of the reactor near the water outlet. The concentrations of three-state nitrogen (nitrate nitrogen, ammonia nitrogen, and nitrite nitrogen) and organic matter (total organic carbon) in the influent and effluent water were regularly measured, and the removal rates of nitrate nitrogen, ammonia nitrogen, nitrite nitrogen, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com