System and method for deeply treating brown alga chemical engineering waste calcium water through double-membrane technology

A technology of advanced treatment and double-membrane method, applied in chemical instruments and methods, water/sewage treatment, flotation water/sewage treatment, etc., can solve the impact of treatment process, increase treatment cost, equipment cost and large-scale floor area and other problems, to achieve the effect of simplifying the process steps, simplifying the pretreatment process, and facilitating the scale-up of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

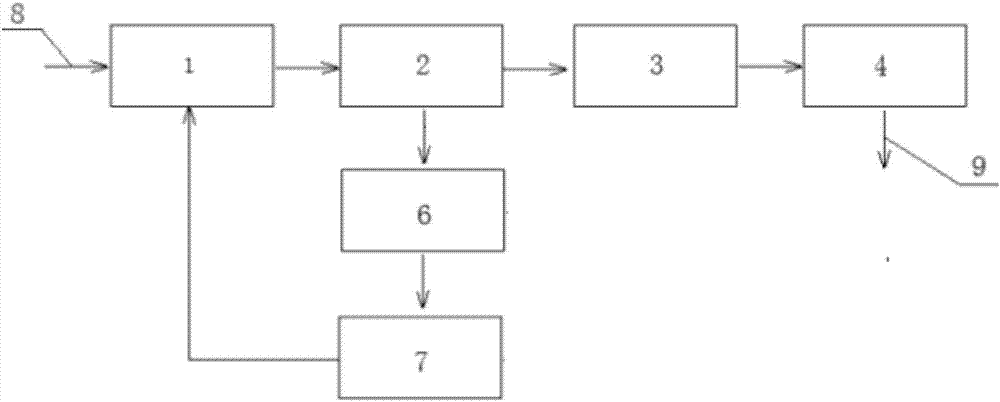

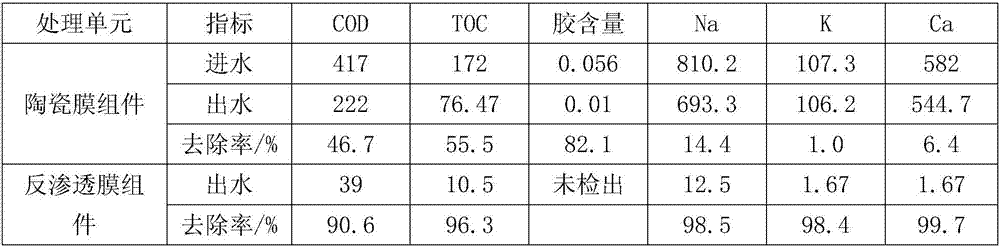

[0024] The method for advanced treatment of brown algae chemical waste calcium water by double-membrane method comprises the following steps:

[0025] (1) A system for advanced treatment of brown algae chemical waste calcium water using a double-membrane method; the ceramic membrane module 2 is a flat ceramic membrane module with a hydrophilic surface, and the average pore size of the ceramic membrane is 100nm; the reverse osmosis membrane module 4 is a hollow reverse osmosis membrane module. Permeable membrane components;

[0026] (2) The brown algae chemical waste calcium water is input into the coagulation-air flotation treatment tank 1 through the brown algae chemical waste calcium water pipeline 8 to remove the alginate and then input into the ceramic membrane module 2, and the filtrate is obtained by separating under the condition of an operating pressure of 0.2 MPa 1 and concentrated water, the filtrate 1 is passed into the activated carbon tank 3 for filtration and the...

Embodiment 2

[0030] The method for advanced treatment of brown algae chemical waste calcium water by double-membrane method comprises the following steps:

[0031] (1) A system for advanced treatment of waste calcium water from brown algae chemical industry using a double-membrane method; the ceramic membrane module 2 is a tubular ceramic membrane module with a hydrophilic surface, and the average pore diameter of the ceramic membrane is 10nm; the reverse osmosis membrane module 4 is a tubular ceramic membrane module. type reverse osmosis membrane module;

[0032] (2) The brown algae chemical waste calcium water is input into the coagulation-air flotation treatment tank 1 through the brown algae chemical waste calcium water pipeline 8 to remove the alginate, and then input into the ceramic membrane module 2, and the filtrate is obtained by separating under the condition of an operating pressure of 0.1 MPa 1 and concentrated water, the filtrate 1 is passed into the activated carbon tank 3 f...

Embodiment 3

[0034] The method for advanced treatment of brown algae chemical waste calcium water by double-membrane method comprises the following steps:

[0035] (1) A system for advanced treatment of waste calcium water from brown algae chemical industry using a double-membrane method; the ceramic membrane module 2 is a tubular ceramic membrane module with a hydrophilic surface, and the average pore size of the ceramic membrane is 200nm; the reverse osmosis membrane module 4 is a flat plate reverse osmosis membrane components;

[0036] (2) The brown algae chemical waste calcium water is input into the coagulation-air flotation treatment tank 1 through the brown algae chemical waste calcium water pipeline 8 to remove the alginate, and then input into the ceramic membrane module 2, and the filtrate is obtained by separating under the condition of an operating pressure of 0.4MPa 1 and concentrated water, the filtrate 1 is passed into the activated carbon tank 3 for filtration and then pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com