Preparation method of anisic acid with high-efficiency and environment-friendly effects

An anisic acid and environment-friendly technology, applied in the field of efficient and environmentally friendly anisic acid preparation, can solve problems such as high pollution and high energy consumption, and achieve the effects of high purity, low energy consumption and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of efficient and environment-friendly preparation method of anisic acid of the present invention comprises:

[0019] (1) Take 100 g star anise fruit and grind it into 60-mesh powder, put it into a 2000 mL hard round bottom flask of volatile oil extractor, then add 800 mL deionized water to soak for 1 h, start heating to 90 °C and Keep the temperature at a constant temperature for 2 hours, and the fennel oil enters the branch pipe of the volatile oil extractor along with part of the water vapor;

[0020] (2) Separate the fennel oil collected in the branch pipe of the volatile oil extractor to remove most of the water, then add 1 g of anhydrous magnesium sulfate to the fennel oil, let it stand for 20 min, heat the mixed solution to 50 °C, and Carry out suction filtration with Buchner funnel while hot, to remove magnesium sulfate, collect filtrate, obtain fennel oil;

[0021] (3) Take 7.5 mL of fennel oil obtained in step (2), add it to a 50 mL round bottom flask, ...

Embodiment 2

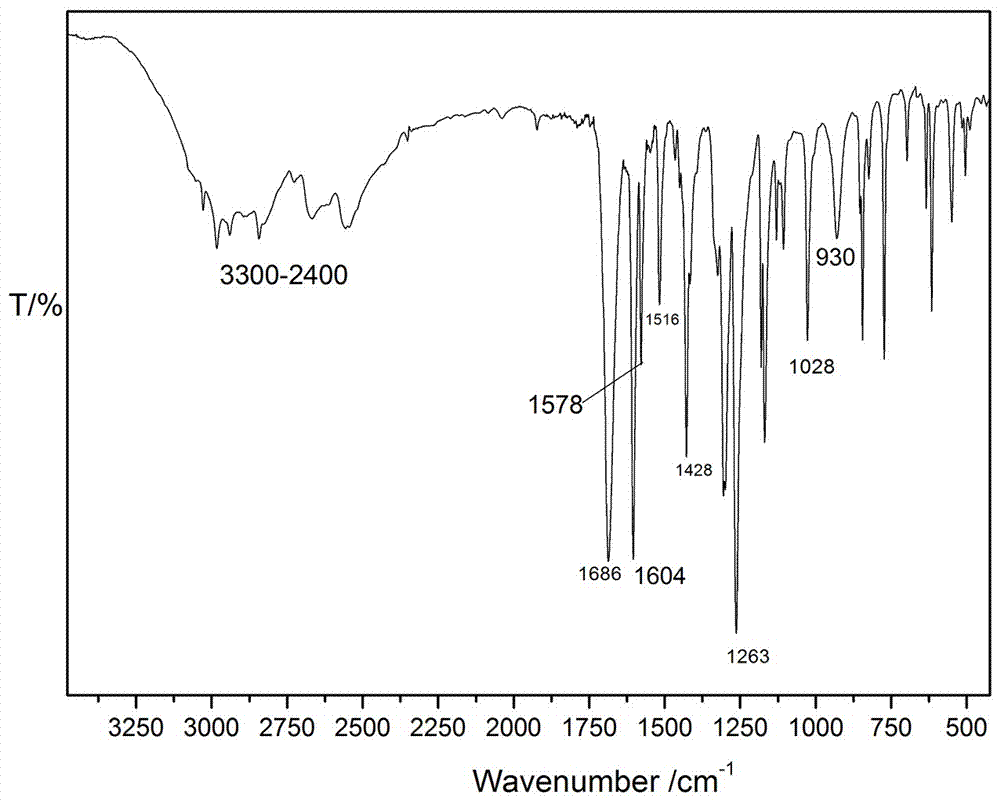

[0025] Carry out infrared spectrum detection to the anisic acid of embodiment 1 gained:

[0026] To compress the blank tablet of potassium bromide and the sample tablet of potassium bromide containing anisic acid, first grind 200 mg of dried potassium bromide in an agate mortar and press it into a blank tablet; then take 1 mg of purified and dried anisic acid and Grind 200 mg of dry potassium bromide in an agate mortar and press it into a sample piece; put the potassium bromide blank piece on the sample holder of the infrared spectrometer to collect the reference background spectrum; then put the sample piece containing anisic acid for Determination, obtain the infrared spectrogram of anisic acid, see figure 1 , and searched and compared with the library. figure 1 Shown at 1604, 1578, 1516, 1428 cm -1 There are 4 characteristic peaks, which are the characteristic peaks of the vibration of the benzene ring skeleton; at 1263, 1068 cm -1 There are absorption peaks, which are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com