Fly ash melting tail gas purification technology

A tail gas purification and fly ash technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of large secondary fly ash, secondary pollution, etc., to reduce economic costs, avoid sewage, and reduce heavy metal enrichment set of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

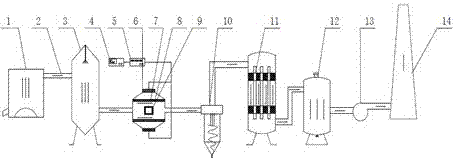

[0036] Such as figure 1 It is the process flow diagram of the present embodiment 1.

[0037] A fly ash melting tail gas purification process: the tail gas generated from the plasma arc fly ash melting furnace 1 enters the water spray desuperheating tower 3 through the high-temperature flue 2, cools down to below 100°C, and then enters the crystal nucleus agglomeration chamber 8, and the crystal nucleus The reunion chamber 8 includes a signal generator 4, a power amplifier 5, a sound unit 6, a standing wave elimination layer 7, and a plexiglass observation port 9, and the plexiglass observation port is connected to the body of the crystal nucleus reunion chamber 8 through a flange. After the fly ash molten tail gas enters the crystal nucleus reunion chamber 8, the acoustic unit of the sound wave sound source system installed in the crystal nucleus reunion chamber increases the amplitude of the sound wave in the crystal nucleus reunion chamber, effectively improving the relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com