Nitrogen-doped carbon nanodot/magnetic metallic oxide composite nanofiber material, preparation method and application thereof

A technology of composite nanofibers and nitrogen-doped carbon, applied in chemical instruments and methods, chemical characteristics of fibers, chemical/physical processes, etc. problems such as easy agglomeration, to achieve the effect of promoting the development and commercialization process, the preparation method is simple, and the catalytic activity is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

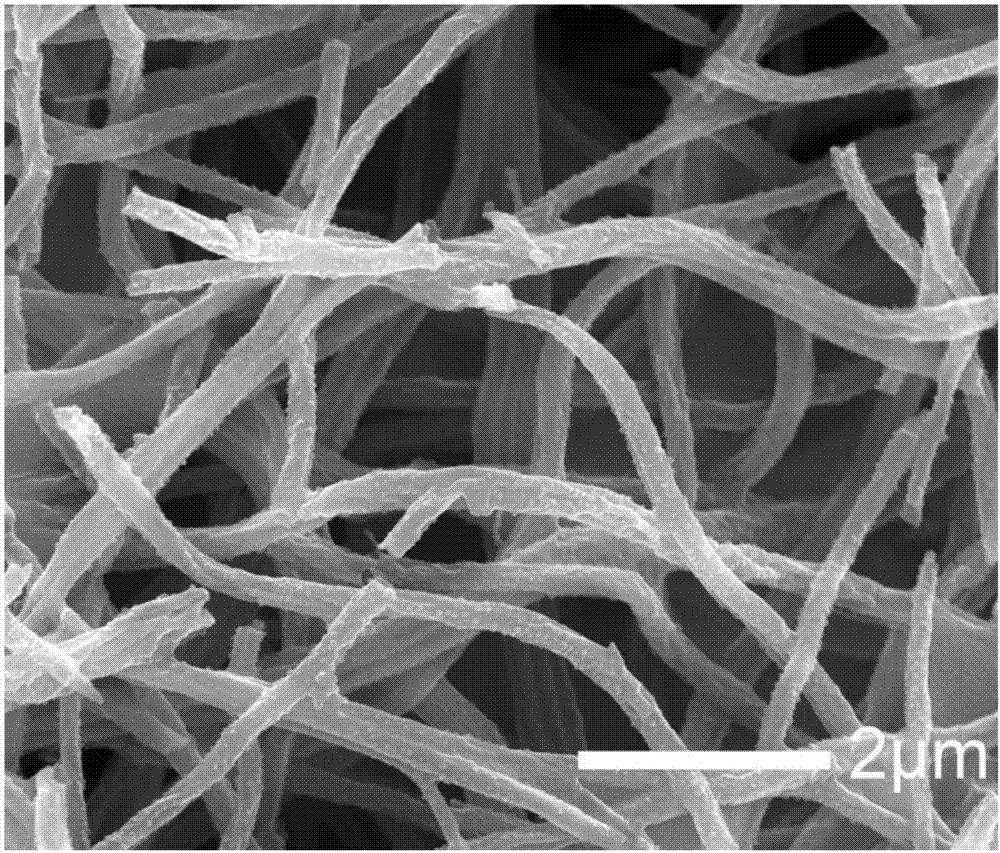

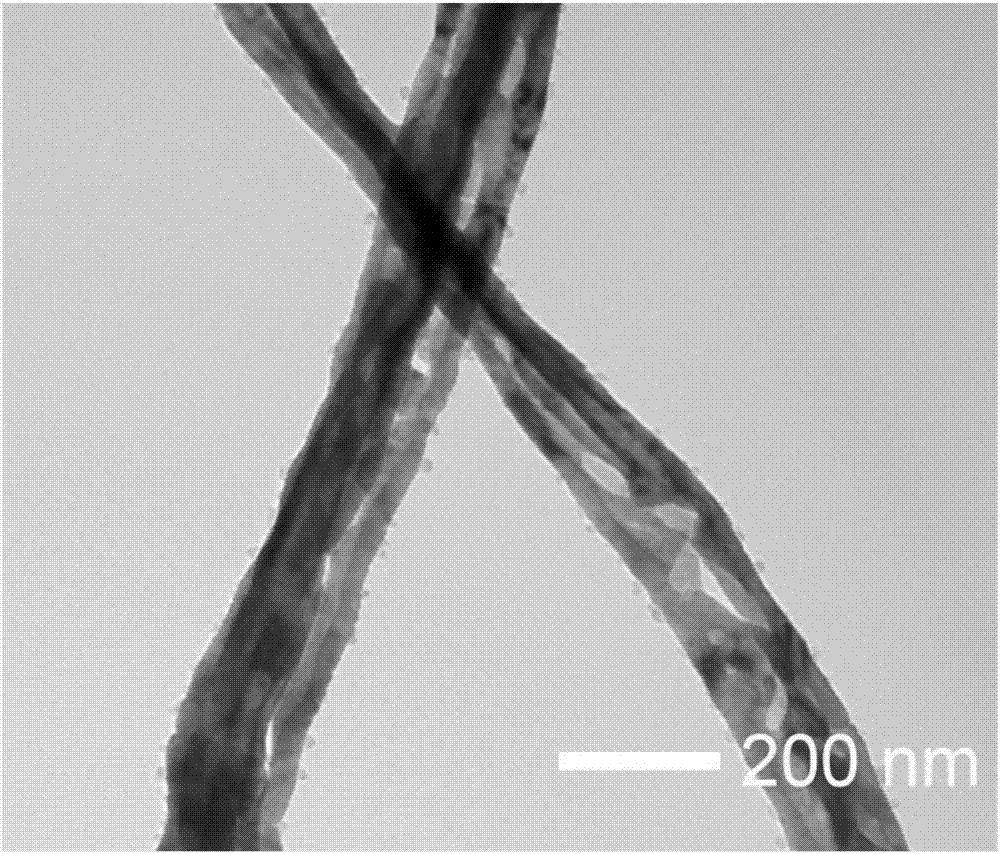

[0025] 0.9 g of ferric nitrate and 0.9 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solution of 5 mL of DMF and 5 mL of isopropanol. Stir magnetically at room temperature to obtain a homogeneous thick spinning solution precursor. The spinning liquid precursor was injected into the glass spinning tube of the electrospinning device, the spinning distance was 20cm, and the spinning voltage was 18kV. The resulting PVP / Fe(NO 3 ) 3 composite nanofibers. PVP / Fe(NO 3 ) 3 The composite nanofibers were calcined in air atmosphere (500°C, 4h) to obtain Fe 2 o 3 Nanofibers. Fe obtained under this condition 2 o 3 The morphology of the nanofibers is all fibrous, the fiber diameter is about 200-300nm, and the quality of the obtained product is about 50mg.

Embodiment 2

[0027]0.9 g of ferric nitrate and 0.4 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solution of 5 mL of DMF and 5 mL of isopropanol. Stir magnetically at room temperature to obtain a homogeneous thick spinning solution precursor. The spinning solution was injected into the glass spinning tube, the spinning distance was 20cm, and the spinning voltage was 18kV. The resulting PVP / Fe(NO 3 ) 3 composite nanofibers. PVP / Fe(NO 3 ) 3 The composite nanofibers were calcined in air atmosphere (500°C, 4h) to obtain Fe 2 o 3 Nanofibers. With respect to embodiment 1, the Fe obtained under this condition 2 o 3 Except that most of the nanofibers are fibrous, the diameter of the fiber is about 100-250nm, and there are a small amount of granular products, and the quality of the obtained product is about 50mg.

Embodiment 3

[0029] 0.9 g of ferric nitrate and 1.5 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solution of 5 mL of DMF and 5 mL of isopropanol. Stir magnetically at room temperature to obtain a homogeneous thick spinning solution precursor. The spinning solution was injected into the glass spinning tube, the spinning distance was 20cm, and the spinning voltage was 18kV. The resulting PVP / Fe(NO 3 ) 3 composite nanofibers. PVP / Fe(NO 3 ) 3 The composite nanofibers were calcined in air atmosphere (500°C, 4h) to obtain Fe 2 o 3 Nanofibers. Fe obtained under this condition 2 o 3 The morphology of the nanofibers is fibrous, but compared with Example 1, the diameter is thicker, the fiber diameter is about 300-500nm, and the quality of the obtained product is about 50mg.

[0030] 2. In situ polymerization to prepare Fe 2 o 3 / polypyrrole composite nanofiber

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com