Methods for Encapsulation of Active Substances in Droplets and Other Compartments

A droplet and liquid technology, applied in chemical instruments and methods, mixing methods, formulations of perfume preparations, etc., can solve the problems of reducing the usable storage life of products and increasing the possibility of payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

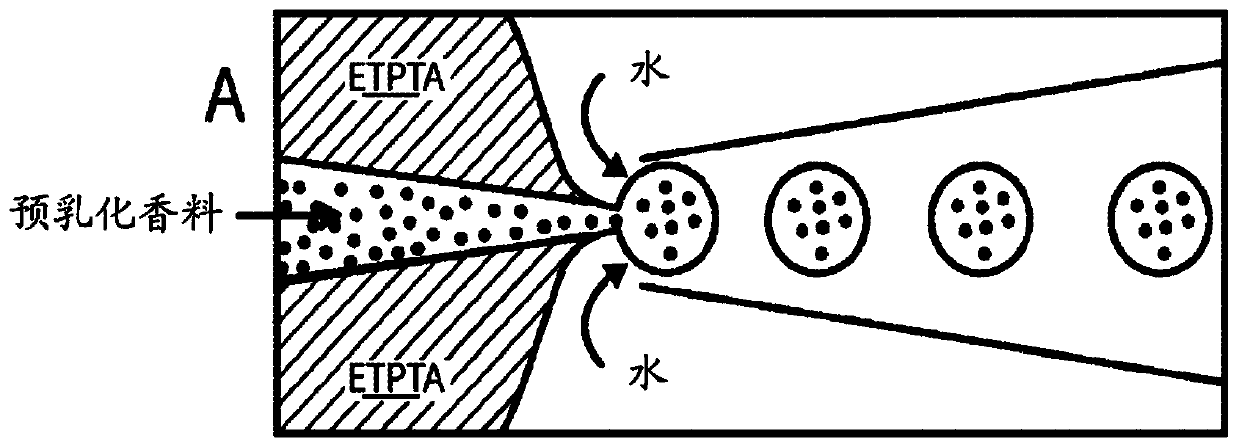

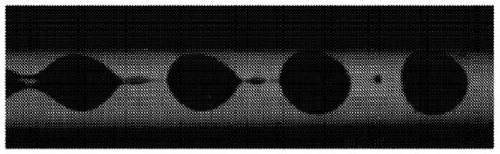

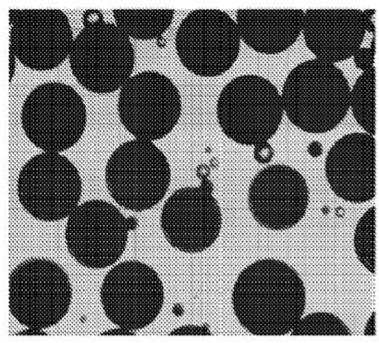

[0161] This example shows the encapsulation of an active substance embedded within a secondary compartment to achieve controlled release characteristics. In this example, fragrance is encapsulated as an exemplary embodiment. Fragrances are usually mixtures of polar and non-polar components (eg fragrance essential oils or aroma compounds). Therefore, encapsulation of fragrances in polymeric shells dispersed in the aqueous phase can be challenging because of their significant sensitivity in a wide range of solvents and even in most shell materials (monomers). Solubility.

[0162] This example shows a method of encapsulating a pre-emulsified fragrance in a hydrophobic polymer shell, achieving high loading efficiencies, eg, over 50%. In this particular example, in order to first form a double emulsion (water-in-oil-in-water), three phases were injected into the microcapillary device: 10% PVA (polyvinyl alcohol) in the water phase as the continuous phase, with a photoinitiator ( ...

Embodiment 2

[0166] In this embodiment, the antioxidant is encapsulated as another exemplary embodiment. see figure 2 .

[0167] A monomer solution of THBQ was prepared. An antioxidant (tert-butylhydroquinone, TBHQ, 600 mg) was dissolved in EtOH (1 mL) in a glass vial. To a vial containing a hydrophobic monomer (pentaerythritol triacrylate, PETA, 3 g) and a photoinitiator (2-hydroxy-2-methylpropiophenone, HMP, 30 mg), a solution of TBHQ in EtOH was added. The solution (2 g) was placed under vacuum for 6 hours to remove EtOH and form a clear viscous fluid of monomer in which TBHQ was dissolved.

[0168] Prepare a water-in-oil emulsion. To the resulting solution was added 8 mL of PVA in water (10% by weight), and the resulting mixture was placed on a vortex for 1 minute. After initial mixing, the cloudy emulsion was subjected to focused sonication for 15 minutes in an ice bath (40% power, 5 sec sonication, 2 sec intervals).

[0169] Synthesis of secondary particle dispersions in water...

Embodiment 3

[0172] Example 3 Preparation of α-pinene-encapsulated ETPTA microcapsules with and without hydrogel network continuous phase in microcapsules. The microcapsules were rinsed with DI water to remove the continuous aqueous phase carrying the microcapsules. After removing the surrounding water, large differences in microcapsule morphology were observed over time. For the control microcapsules, the water phase of the fragrance emulsion was replaced by air as the water evaporated. For PEG hydrogel microcapsules, no significant difference was observed. Upon rupture, a uniform hydrogel network in the PEG hydrogel microcapsules was observed. Such as Figure 5 As shown in , the control microcapsules had a dispersed phase retention of less than about 40% w / w after 5 days, while the hydrogel continuous phase microcapsules had a dispersed phase retention of about 50% w / w.

[0173] The various embodiments described above can be used as part of a range of consumer product formulations. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com