Method for extracting beta-glucan from black highland barley bran

A technology for highland barley bran and glucan is applied in the field of deep processing and comprehensive utilization of grain bran and extraction of beta-glucan, which can solve the problems of complicated purification method and low glucan extraction rate, and achieves the improvement of extraction rate. , the effect of good source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

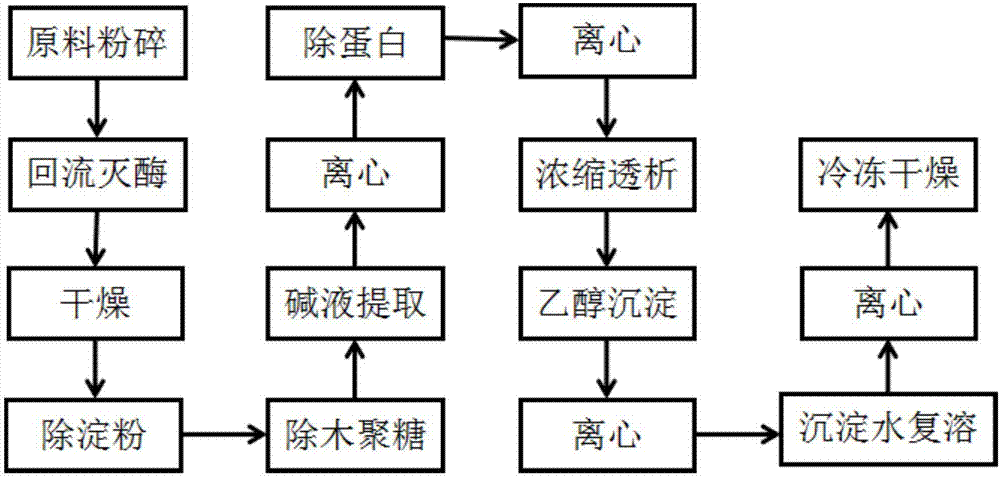

Method used

Image

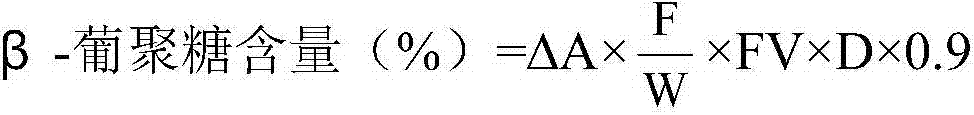

Examples

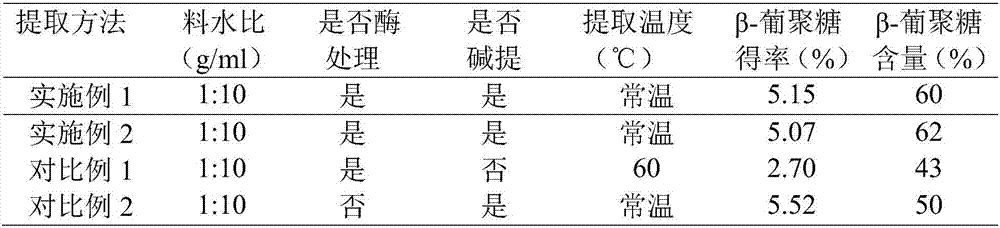

Embodiment 1

[0031] Weigh 50g of black highland barley bran, pass through a 60-mesh sieve after crushing, add 500ml of ethanol (85%), and reflux at 85°C for 2h. In order to achieve the inactivation of endogenous glucanase in raw materials, and play the role of degreasing, decoloring, and removing small molecules. Dry overnight at 40°C to obtain pretreated black highland barley bran powder. The pretreatment preliminarily eliminated some impurities in the subsequent extraction of black barley bran β-glucan, which improved the purity of β-glucan.

[0032] Take by weighing 40g black highland barley bran pretreatment powder, in the black highland barley bran pretreatment powder according to mass volume ratio (w / v) be 1:10 add solvent deionized water, promptly add the deionized water of 400ml , heated in a water bath at 90°C, added high temperature resistant α-amylase and stirred evenly until the iodine-potassium iodide solution did not show blue color. Adjust the pH value to 5 with 1M hydroch...

Embodiment 2

[0034] The method of pretreating black highland barley bran to obtain pretreatment powder is as described in Example 1. Take 30g of pretreated black highland barley bran powder, add 300ml of deionized water as a solvent, heat in a water bath at 90°C, add high temperature resistant α-amylase and stir evenly until the iodine-potassium iodide solution does not show blue. Adjust the pH value to 5 with 1M hydrochloric acid, add xylanase to it, bathe in water at 50-60°C for 30 minutes, and then adjust the pH value to 7 with 1M NaOH. Make up deionized water until the ratio of solid to liquid is 1:10, add NaOH to the mixed solution after removing starch and xylan to a concentration of 1%, extract at room temperature for 2 hours, and keep stirring. After centrifugation at 4000r for 20min, the residue was discarded, and the supernatant was taken for later use. Adjust the pH value of the supernatant to 4.5 with 2M hydrochloric acid, let stand at 4°C for 6 hours, centrifuge at 4000r for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com