A preparation method and device for a polypeptide with a controllable molecular weight range

A molecular weight and molecular weight cut-off technology, applied in the biological field, can solve problems such as difficult peptides, difficult to prepare peptides, and protease residues in enzymatic hydrolysis products, and achieve the effects of increasing unit loading, improving enzymatic hydrolysis efficiency, and reducing steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

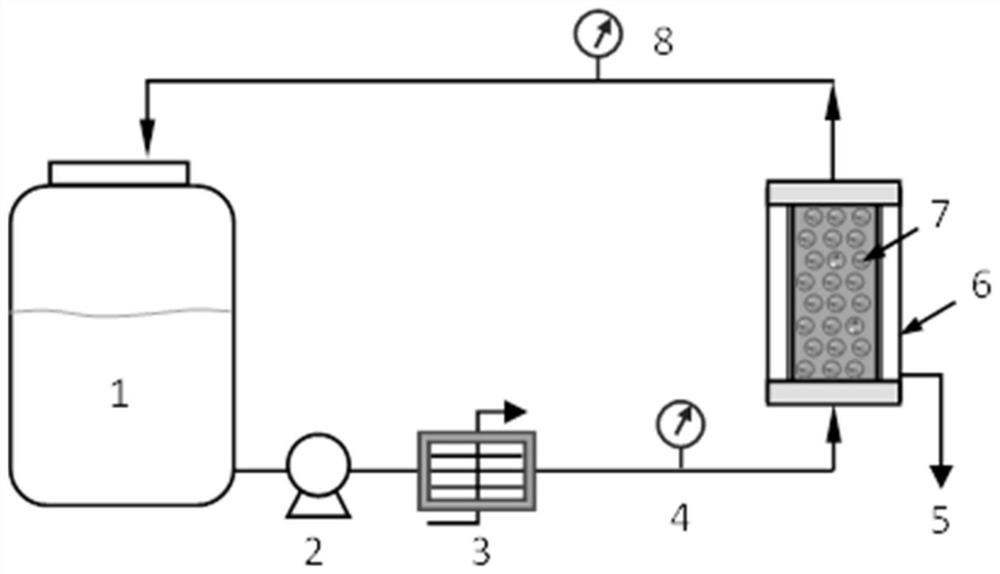

[0063] Example 1 A preparation device for a polypeptide with a controllable molecular weight range

[0064] A preparation device for polypeptides with a controllable molecular weight range, such as figure 1 As shown, the device includes a protein solution storage bottle 1, a fluid delivery pump 2, a heat exchanger 3 and a tubular ceramic membrane 6 connected in sequence;

[0065] Porous microspheres 7 loaded with immobilized enzymes are filled in the tubular ceramic membrane 6;

[0066] The filling volume of the porous microsphere 7 loaded with immobilized enzyme is 60-100% of the inner pore volume of the tubular ceramic membrane 6, preferably 70-90%;

[0067] The inner hole diameter of the tubular ceramic membrane 6 is 1-30mm, preferably 3-20mm;

[0068] The molecular weight cut-off range of the tubular ceramic membrane 6 is 1-800kDa, preferably 3-500kDa, more preferably 5-300kDa;

[0069] Both the inlet and the outlet of the tubular ceramic membrane 6 are provided with sc...

Embodiment 2

[0078] The raw material is soybean protein isolate with an average molecular weight greater than 23kDa, and the protein content exceeds 93% (dry basis). Weigh 5kg of soybean protein isolate and prepare 80L of a solution with a concentration of 6.25%:

[0079] (1) Enzyme immobilization: Pepsin is covalently coupled to porous ceramic microspheres with a diameter of 0.5 mm. The loading capacity of the pepsin is 10 mg / g. The diameter range is 100nm-20μm;

[0080] (2) Membrane loading: The ceramic microspheres loaded with pepsin are loaded into a tubular ceramic membrane with an inner diameter of 5 mm. The molecular weight cut-off of the ceramic membrane is 5 kDa. Microsphere encapsulation, the filling volume of porous ceramic microspheres loaded with pepsin in the ceramic membrane is 80% of the total volume of the pores in the ceramic membrane;

[0081] (3) Synchronous enzymatic hydrolysis-ultrafiltration process: put 80L soybean protein isolate solution with a concentration of 5...

Embodiment 3

[0085] The raw material is gelatin with an average molecular weight greater than 80kDa, and the protein content exceeds 96% (dry basis). Take 10kg of the gelatin and configure it into 100L of a 10% solution:

[0086] (1) Enzyme immobilization: Trypsin is covalently coupled to porous glass microspheres with a diameter of 1 mm. Pore diameter ranges from 200nm to 10μm;

[0087] (2) Membrane loading: the glass microspheres loaded with trypsin are packed into a tubular ceramic membrane with an inner hole diameter of 10 mm, the molecular weight cut-off of the ceramic membrane is 30 kDa, and the inlet and outlet of the ceramic membrane are provided with screens with a pore size of 0.02 mm. The filling volume of the porous glass microspheres loaded with trypsin in the ceramic membrane is 75% of the total volume of the pores in the ceramic membrane;

[0088] (3) Synchronous enzymolysis-ultrafiltration process: put 100L gelatin solution with a concentration of 10% in a 200L stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bore diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com