Determination method for gold and palladium in decoppered slag produced in wet treatment process for copper anode slime

A technology for wet processing and copper anode slime, which can be used in measurement devices, preparation of test samples, and color/spectral characteristics measurement, etc., and can solve problems such as high cost, large pollution, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

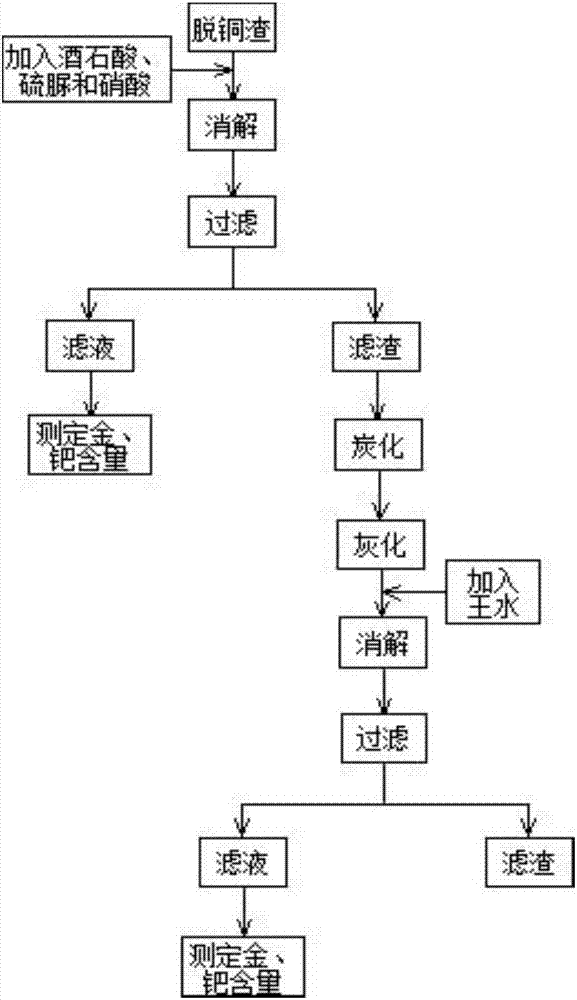

Method used

Image

Examples

Embodiment

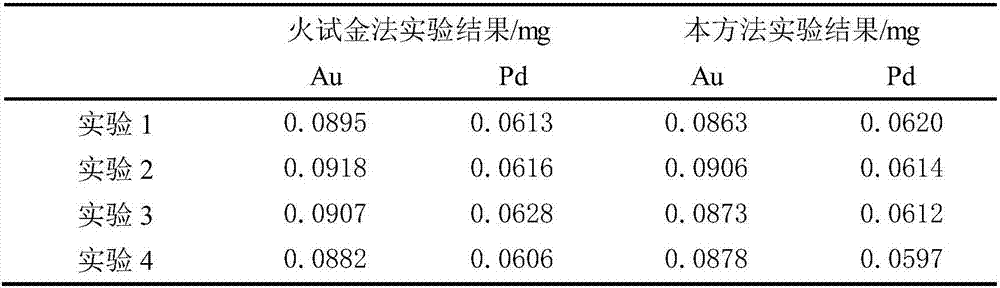

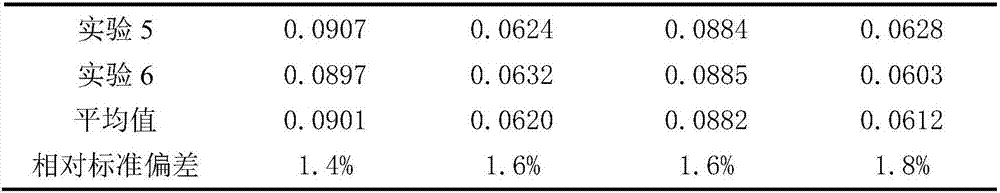

[0025] Control group experiment: According to the YST 745.2-2010 method of the non-ferrous standard, accurately weigh 1.0000g of the sample, and mix the sample, anhydrous sodium carbonate, lead oxide, silicon dioxide, Borax and starch are mixed and placed in an assay gold crucible, stirred evenly, and covered with sodium chloride with a thickness of about 10 mm. Place the crucible in a gold assay furnace at 900°C, close the furnace door, raise the temperature to 1100°C within 45-60 minutes, keep it warm for 5 minutes, and then come out of the furnace. Pour the melt into a preheated cast iron mold. After cooling, separate the lead buckle from the slag, and hammer the lead buckle into a cube.

[0026] Put the lead button into the ash dish that has been preheated in the gold assay furnace at 900°C for 20 minutes, close the furnace door for 1-2 minutes, and after the molten lead is demoulded, open the furnace door halfway, and control the furnace temperature at 880°C for ash blow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com