Method for preparing Fe/N co-doped-TNTs (TiO2 nano-tubes)-reduced graphene oxide composite catalysts

A graphene composite and composite catalyst technology, applied in the field of photocatalytic degradation of organic pollutants, can solve problems such as light propagation without consideration, achieve the goal of improving free carrier density, improving photocatalytic degradation ability, and reducing catalytic degradation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

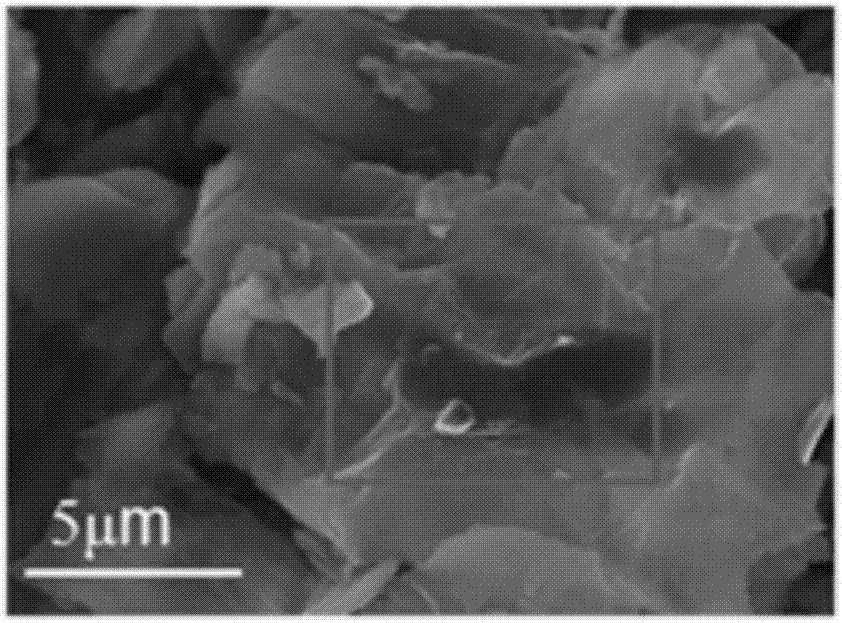

[0041] The specific preparation method of the present embodiment Fe / N co-doped-TNTs-graphene oxide composite catalyst is as follows:

[0042] 1. Preparation of graphene oxide GO: add 3.75g NaNO to a beaker 3 , 5g graphite, 150mL concentrated H 2 SO 4 , 20gKMnO 4 , H 2 o 2 (30 mL, 30%) was vigorously stirred; after the chemical reaction was completed, GO was separated from the mixture by different centrifugation speeds to obtain graphene oxide GO.

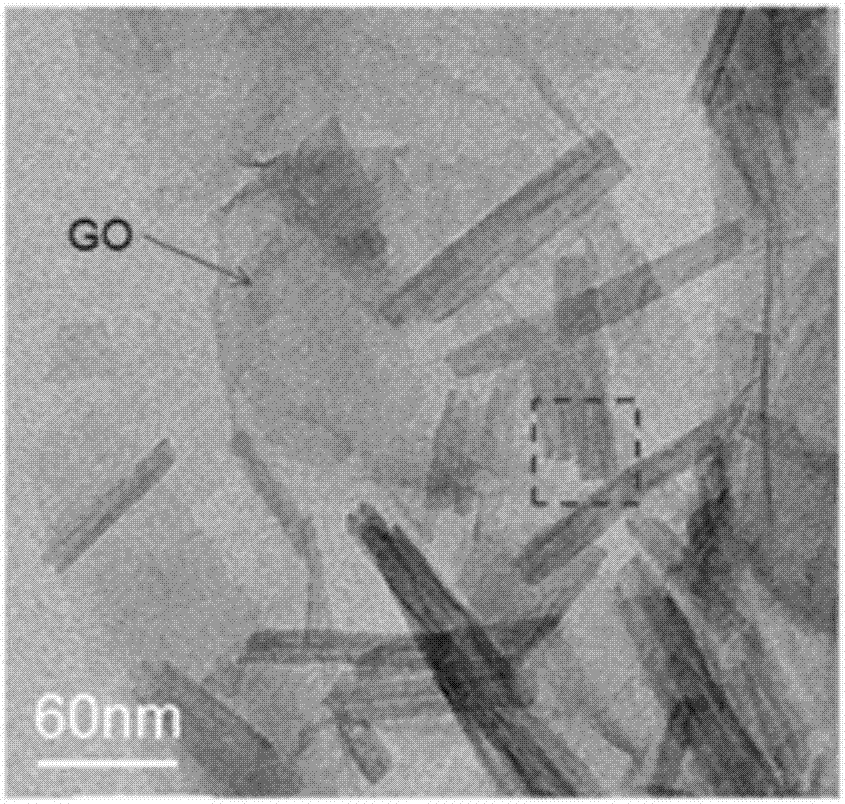

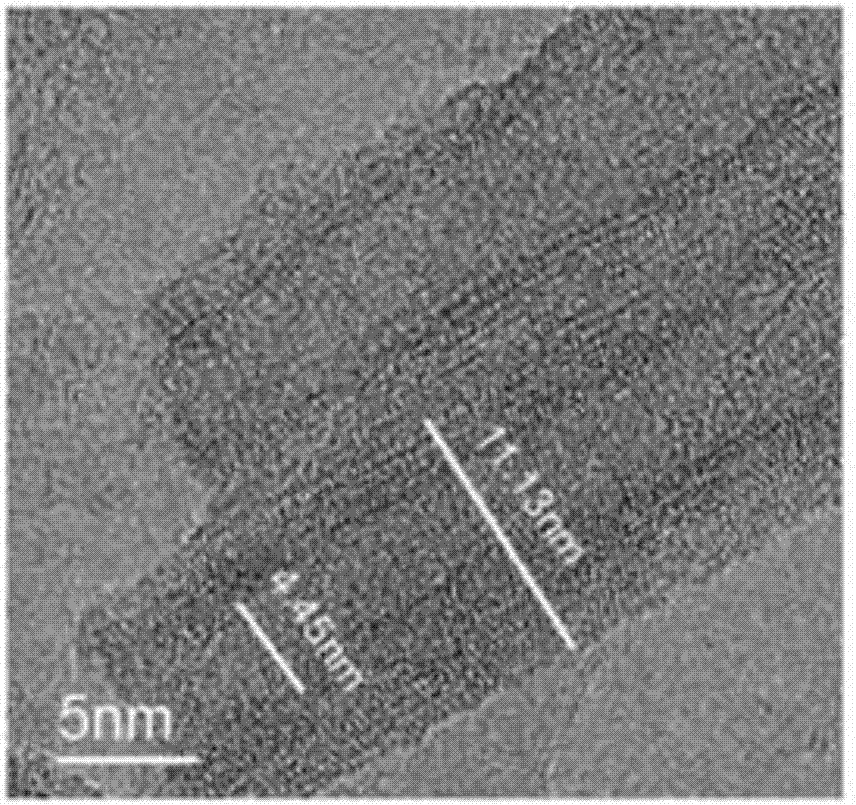

[0043] 2. Preparation of TiO by hydrothermal method 2 Nanotubes (TNTs): 0.70gTiO 2 The powder was dissolved in 10 mL of deionized water, then the mixture and NaOH solution (60 mL, 10 mol / L) were added to a 100 mL Teflon stainless steel autoclave and stirred vigorously at 130 °C for 24 hours, the precipitate was separated and dried at 60 °C to obtain TiO 2 nanotubes (TNTs).

[0044] 3. Fe mixed with TiO 2 Preparation of nanotubes: the TNTs prepared in the above step 2) and Fe(NO 3 ) 3 9H 2 O mixed, the mixture was dried a...

Embodiment 2

[0049] The specific preparation method of the present embodiment Fe / N co-doped-TNTs-graphene oxide composite catalyst is as follows:

[0050] 1. Preparation of graphene oxide GO: add 2.75g NaNO to a beaker 3 , 2.5g graphite, 150mL concentrated H 2 SO 4 , 15g KMnO 4 , H 2 o 2 (20 mL, 30%) was vigorously stirred; after the chemical reaction was completed, GO was separated from the mixture by different centrifugation speeds.

[0051] 2. Preparation of TiO by hydrothermal method 2 Nanotubes (TNTs): 0.60g TiO 2 The powder was dissolved in 10 mL of deionized water, then the mixture and NaOH solution (60 mL, 10 mol / L) were added to a 100 mL Teflon stainless steel autoclave and stirred vigorously at 130 °C for 24 hours, the precipitate was separated and dried at 60 °C to obtain TiO 2 nanotubes (TNTs).

[0052] 3. Fe mixed with TiO 2Preparation of nanotubes: the TNTs prepared in the above step 2) and Fe(NO 3 ) 3 9H 2 O mixed, the mixture was dried at 60 °C, and calcined at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com