Method for separating chemical components of pine needles

A separation method and technology for chemical components, which can be used in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., and can solve the problems of long cycle, difficult industrial production, and poor repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment one pine leaf extract

[0040] Fresh pine leaves, add ZNTD-50 extraction and concentration unit, add water to decoct twice, add 8 times the amount of water for the first time, decoct for 1.5 hours, add 6 times the amount of water for the second time, decoct for 1.5 hours; the filtrate is concentrated under reduced pressure Form the extract whose relative density is 1.2 at 70°C; spray dry to obtain.

Embodiment 2

[0041] Example 2 Traditional phytochemical separation method to prepare pine needle compound

[0042] (1) Preparation of test solution

[0043] Take 1200g of pine leaf extract, extract with ethyl acetate and water-saturated n-butanol successively to obtain ethyl acetate extraction extract, water-saturated n-butanol extraction extract and the remaining extract from the water layer, and the numbers are Pr.1~ 3. Time-consuming 5d.

[0044] (3) Rough classification

[0045] Take Pr.2 (water-saturated n-butanol extract), absorb it with macroporous resin D101, elute with 3 times the column volume of water, then separate through SBC MCI gel, and elute with 3 times the column volume of 30% ethanol to obtain Pr. .2A1, separated by eluting with 3 times column volume of 40% ethanol to obtain Pr.2A2. Time consuming 3d.

[0046] Take Pr.2A2 (40% ethanol eluent) and pass through Sephadex G25 column, eluted with 3 times column volume of water to obtain 3 parts Pr.2A2A, Pr.2A2B, and Pr.2...

Embodiment 3

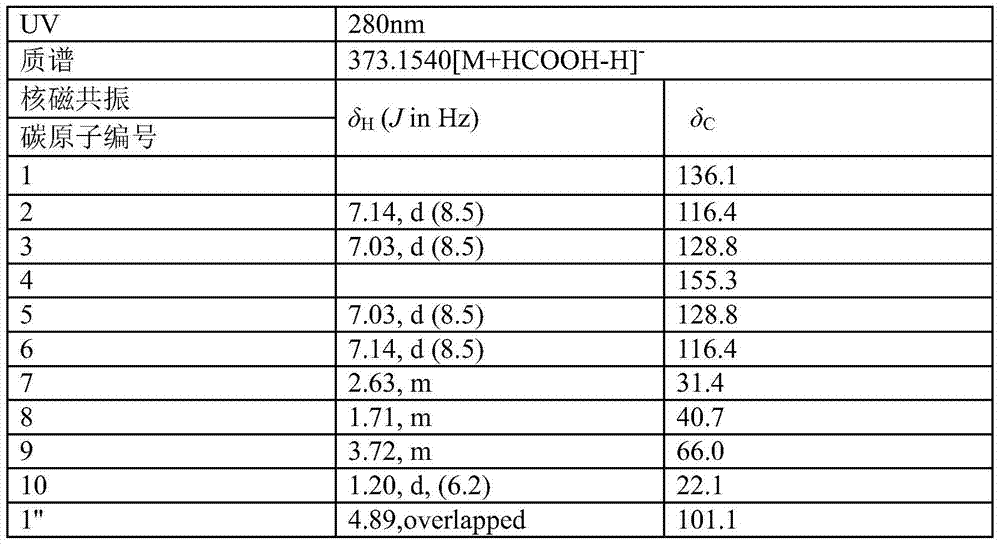

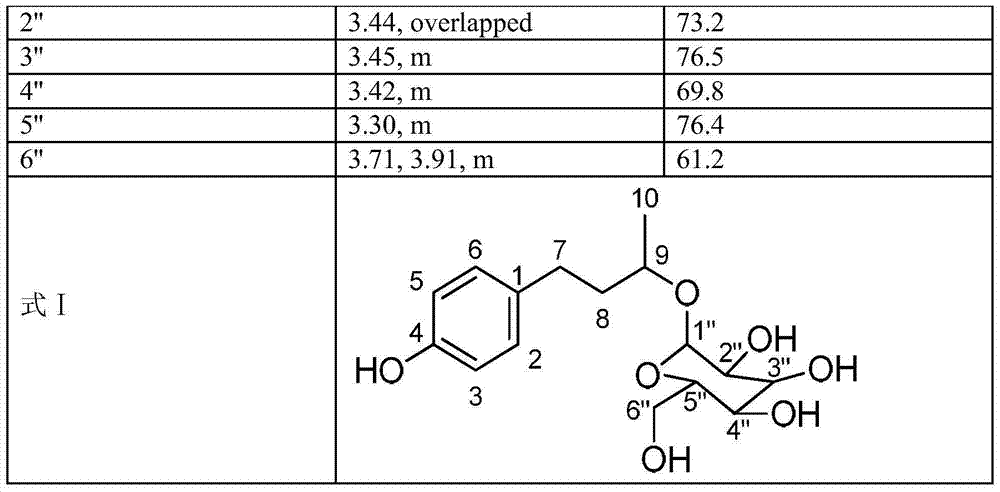

[0059] The preparation of embodiment three pine needle compounds

[0060] (1) Preparation of test solution

[0061] Weigh 35g of pine leaf extract, add 500mL methanol in two times, sonicate for 1 hour each time, let it stand for precipitation, take the supernatant, evaporate in vacuum at 60°C, freeze-dry after concentration, and dissolve the dried product in 40mL supernatant Pure water, through 0.45μm filter membrane, that is. It takes 9 hours.

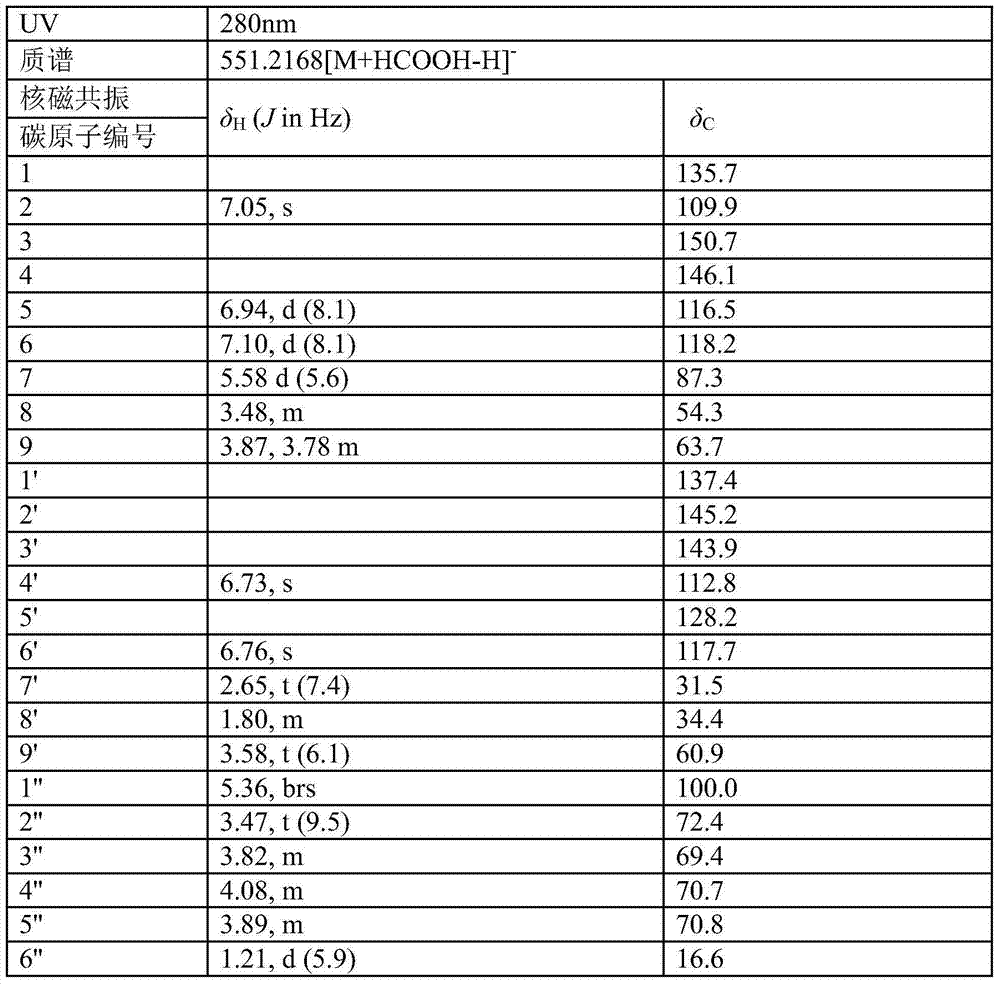

[0062] (2) One-dimensional preparative liquid phase separation

[0063] Instrument: Waters purification factory, chromatographic column: XAqua C18 (250mm×20mm×10μm), each injection volume is 8mL. Use water (aqueous phase) containing 0.1% formic acid and methanol (organic phase) containing 0.1% formic acid as the mobile phase for gradient elution, the elution conditions are 0-35min, 25%-60% organic phase, 35-36min , 60%-95% organic phase, 36-55min, 95%-95% organic phase, the flow rate is 20mL / min, and the detection wavelength is 28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com