Graphene-based waterborne gravure ink and preparation method thereof

A kind of gravure ink, graphene water-based technology, applied in the field of graphene water-based gravure ink and its preparation, can solve the problems of application limitations, poor conductivity, poor stability, etc., achieve strong color development, good thermal stability, overcome water resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of graphene water-based gravure printing ink, comprises the component of following mass percentage:

[0032] Conductive filler 3%-10%, water-based resin 0.5%-10%, water-soluble resin 2.5%-40%, water emulsion 2.5%-40%, dispersant 0.1%-1%, additive 1%-5%, alcohol Solvent-like 44%-89.9%; wherein, the conductive filler is mixed with conductive carbon black and graphene at a mass ratio of 0.1-10:1, and the graphene is graphene powder or graphene aqueous slurry.

[0033] In this embodiment, the water-based resin is an aqueous dispersion of acrylic resin, alkyd resin, fluorocarbon resin, vinyl acetate resin, polyester resin, polyurethane resin, epoxy resin, polyacrylamide resin, polyvinyl alcohol, polyvinyl alcohol One kind of ethylene glycol resin, natural polymer sugar and its derivatives or a mixture of multiples in any proportion.

[0034] In this embodiment, the water-soluble resin is one of acrylic resin, alkyd resin, fluorocarbon resin, vinyl acetate resin, poly...

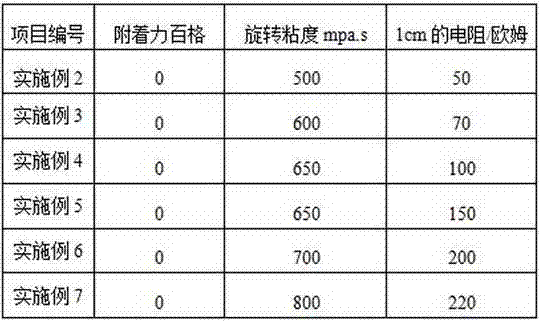

Embodiment 2

[0041] A kind of graphene water-based gravure printing ink, comprises the component of following mass percentage:

[0042] Conductive filler 3%, water-based resin 0.5%, water-soluble resin 2.5%, water emulsion 10%, dispersant 0.1%, auxiliary agent 1%, alcohol solvent 82.9%; wherein, the conductive filler is made of conductive carbon black and graphene Mixed according to the mass ratio of 0.1:1.

[0043] In this embodiment, the water-based resin is an acrylic resin, the water-soluble resin is an alkyd resin, and the water emulsion is an acrylic emulsion.

[0044] In this embodiment, the dispersant is sodium dodecylbenzenesulfonate. The auxiliary agent includes defoamer, leveling agent and anti-settling agent mixed in any proportion, wherein, the defoamer is a lower alcohol, the leveling agent is an acrylic acid copolymer, and the water-based anti-settling agent is Organic bentonite.

[0045] Present embodiment also provides a kind of preparation method of graphene water-base...

Embodiment 3

[0049] A kind of graphene water-based gravure printing ink, comprises the component of following mass percentage:

[0050] Conductive filler 10%, water-based resin 10%, water-soluble resin 15%, water emulsion 2.5%, dispersant 1%, auxiliary agent 5%, alcohol solvent 56.5%; wherein, the conductive filler is made of conductive carbon black and graphene Mixed according to the mass ratio of 10:1.

[0051] In this embodiment, the water-based resin is a mixture of alkyd resin, fluorocarbon resin, vinyl resin and polyester resin in any proportion, and the water-soluble resin is acrylic resin, alkyd resin and fluorocarbon resin in any proportion. The mixing of the water emulsion is the mixing of alkyd emulsion, fluorocarbon emulsion, vinyl acetate emulsion and polyester emulsion in any proportion.

[0052] In this embodiment, the dispersant is a mixture of sodium dodecylbenzenesulfonate, sodium dodecylsulfate and cetylammonium bromide in any proportion.

[0053] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com