Cadmium-telluride film solar cell and preparation method

A technology of solar cells and cadmium telluride, applied in the field of solar cells, can solve the problems of scarce materials, high production cost, high cost, etc., and achieve the effects of good quantum efficiency, cost control, and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

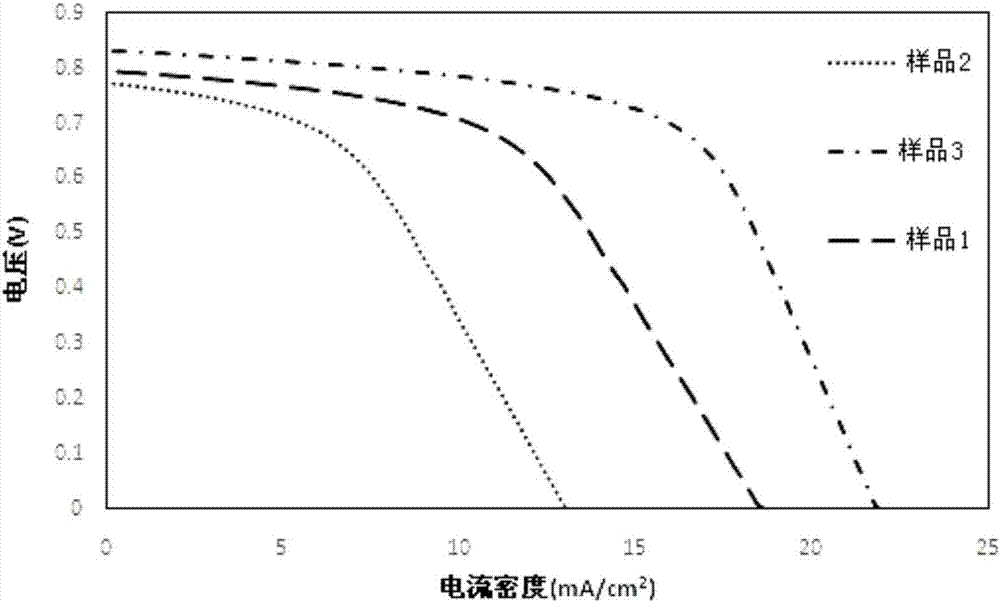

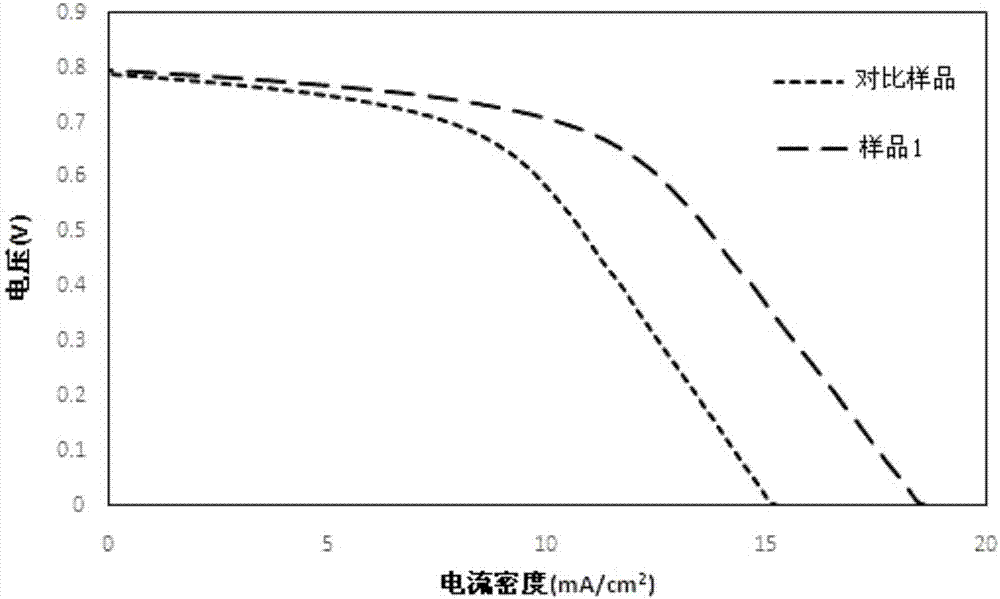

Embodiment 1

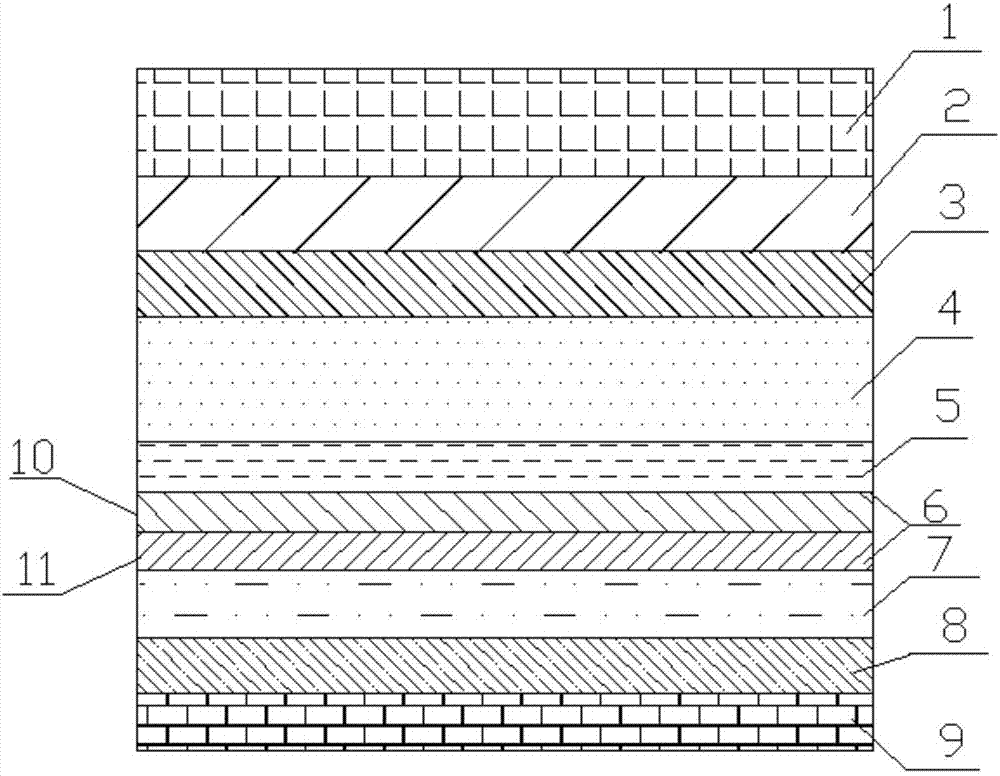

[0039] Such as figure 1 A cadmium telluride thin-film solar cell shown includes a substrate 1, and a laminated film is arranged on the substrate 1, and the laminated film includes a transparent conductive film 2, a window layer 3, an optical Absorbing layer 4, back contact layer 5, back reflection layer 6, back electrode layer 7, encapsulation material layer 8 and back plate 9; Wherein, described substrate 1 is glass or high molecular polymer, and described high molecular polymer is polyimide; the transparent conductive film 2 is a TCO film; the window layer 3 is a cadmium sulfide film layer with a thickness of 10nm to 200nm; the light absorbing layer 4 is a cadmium telluride film layer with a thickness of 500nm; Described back contact layer 5 is cuprous thiocyanate film layer, and thickness is 20nm; Described back reflection layer 6 is silver film layer, and thickness is 80nm; Described back electrode layer 7 comprises nickel film layer 10 and chromium film layer 11, The bac...

Embodiment 2

[0042] This embodiment is except following feature, and other is all identical with embodiment 1:

[0043] In the preparation method of the cadmium telluride thin-film solar cell in this embodiment: the window layer 3 and the light absorbing layer 4 are deposited by the near-space sublimation method, the back contact layer 5 is deposited by thermal evaporation, and the thermal evaporation deposition evaporates The source temperature is 600° C., and the evaporation pressure is 300 Pa.

Embodiment 3

[0045] This embodiment is except following feature, and other is all identical with embodiment 1:

[0046] In the preparation method of the cadmium telluride thin-film solar cell in this embodiment: the window layer 3 and the light absorbing layer 4 are deposited by the near-space sublimation method, the back contact layer 5 is deposited by thermal evaporation, and the thermal evaporation deposition evaporates The source temperature is 300° C., and the evaporation pressure is 10 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com