Ore-dressing method for low-grade lead sulfide ore

A beneficiation method, a technology of lead sulfide ore, applied in flotation, solid separation, etc., can solve the problems of complex steps in the beneficiation process of lead coarse concentrate, increase the difficulty and cost of smelting, reduce the recovery rate of smelting, and achieve cost reduction. Low, high grade, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

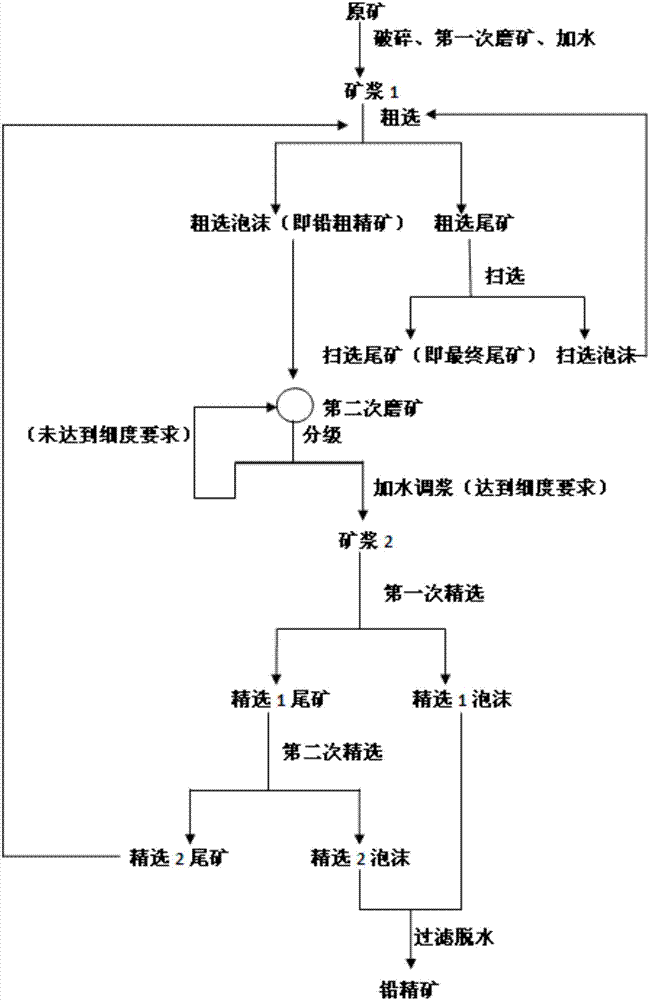

Method used

Image

Examples

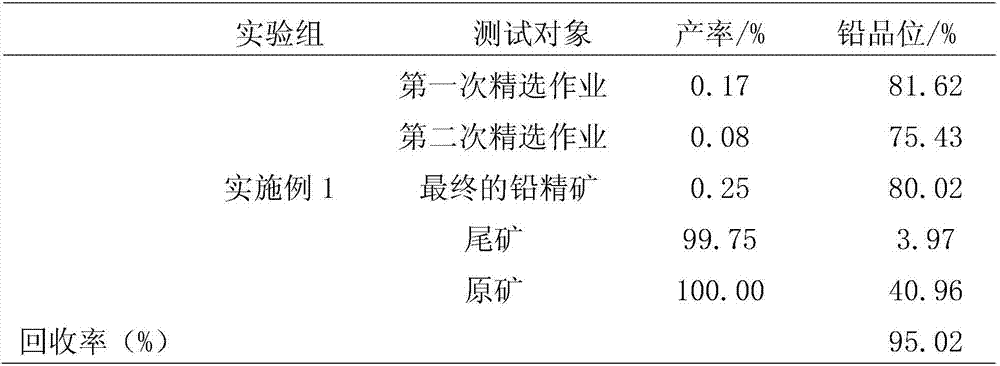

Embodiment 1

[0052] The specific operation steps are as follows:

[0053] (1) Preliminary work: crush the raw ore and grind the ore for the first time, so that the content of the mineral powder with a fineness of less than 0.074mm reaches 48%. Add water to the mineral powder and stir evenly to obtain the ore pulp 1. The mass fraction of the ore pulp 1 is 39%. .

[0054] (2) Rough separation operation: add water glass 38g / t to the rough separation tailings, stir for 10 minutes, then add ethyl sodium xanthate 11g / t and terpineol oil 9g / t, stir for 1 minute and then carry out rough separation , the roughing time is 5 minutes, and roughing tailings and roughing foam are obtained, and the roughing foam is lead rough concentrate.

[0055] (3) Sweeping operation: Add ethyl sodium xanthate 6g / t and terpineol oil 3g / t to the roughing tailings, stir for 1 minute and then sweep for 1 minute to obtain the scavenging tails ore and scavenging froth, the scavenging froth returns to the rougher operatio...

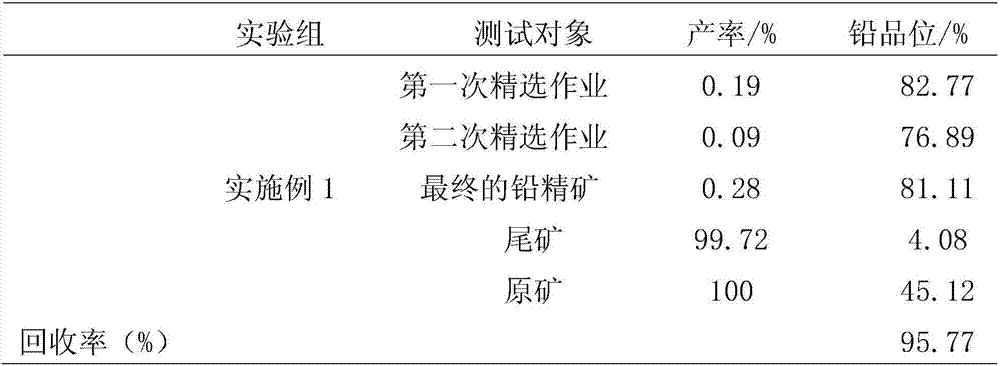

Embodiment 2

[0066] The specific operation steps are as follows:

[0067] (1) Preliminary work: crush the raw ore and grind the ore for the first time, so that the content of ore powder with a fineness less than 0.074mm reaches 52%, add water to the ore powder and stir evenly to obtain ore pulp 1, the mass fraction of ore pulp 1 is 42% .

[0068] (2) Rough separation operation: Add 42g / t of water glass to the rough separation tailings, stir for 15 minutes, then add 13g / t of ethyl sodium xanthate and 7g / t of terpineol oil, stir for 3 minutes and then carry out rough separation , the roughing time is 8 minutes, and the roughing tailings and roughing foam are obtained, the roughing foam is lead rough concentrate, and the lead content of the lead rough concentrate is 45.11%.

[0069] (3) Sweeping operation: Add ethyl sodium xanthate 7g / t and terpineol oil 4g / t to the roughing tailings, stir for 3 minutes and then sweep for 3 minutes to get the scavenging tails ore and scavenging froth, the s...

Embodiment 3

[0080] The specific operation steps are as follows:

[0081] (1) Preliminary work: Crushing the raw ore and grinding the ore for the first time, so that the content of the ore powder with a fineness less than 0.074mm reaches 49%. Add water to the ore powder and stir evenly to obtain the ore pulp 1. The mass fraction of the ore pulp 1 is 40%. .

[0082] (2) Rough separation operation: Add 40g / t of water glass to the rough separation tailings, stir for 13 minutes, then add 12g / t of ethyl sodium xanthate and 8g / t of terpineol oil, stir for 2 minutes before rough separation , the roughing time is 7 minutes, and the roughing tailings and roughing foam are obtained, the roughing foam is lead rough concentrate, and the lead content of the lead rough concentrate is 48.42%.

[0083] (3) Sweeping operation: add ethyl sodium xanthate 6g / t and terpineol oil 3g / t to the roughing tailings, stir for 2 minutes and then sweep, and the sweeping time is 2 minutes to obtain the scavenging tails ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com