Thermal anti-icing / deicing systems include gas thermal anti-icing and electric thermal anti-icing / deicing. Gas thermal anti-icing / deicing generally takes the heat from the

jet engine as the heat source, which is input to the heater on the

skin surface through the control valve. , to heat the surface to achieve deicing, this technology works reliably, but the heat

utilization rate is low, and the

layout of the pipeline is relatively complicated

The above-mentioned deicing systems are mostly designed for deicing the surface of aircraft, but they are not completely suitable for ships and ships sailing in low-temperature and humid environments. It is not only complicated to construct a de-icing system suitable for ships and ships based on the above technologies , and expensive

[0004] After searching the literature of the prior art, it was found that in the patent of Chinese application publication number: CN105517215A, titled "a low-

voltage transparent electric

heating film and its preparation process, a high-temperature electric heating sheet and its preparation process", it is proposed that the transparent electric

heating film includes glass Transparent substrate,

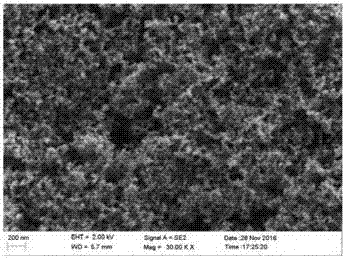

carbon nanotube or

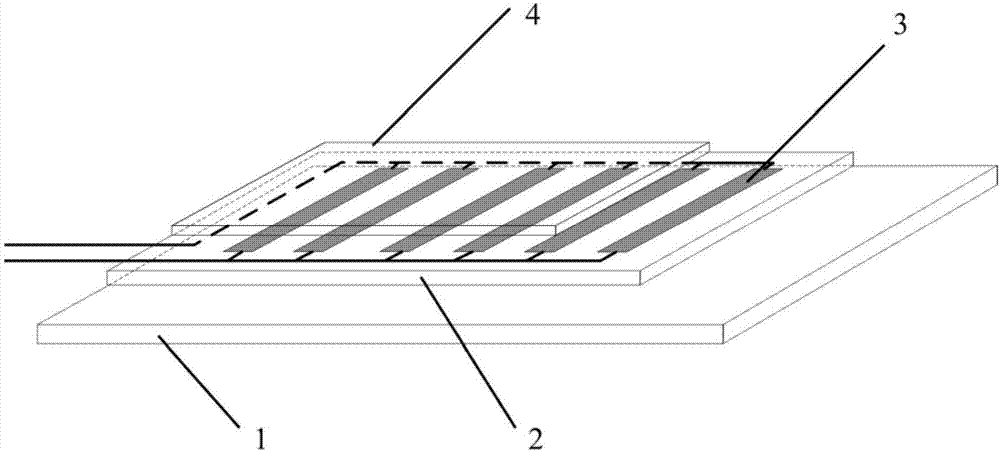

graphene transparent conductive layer and electrodes; the transparent conductive layer is formed on at least one side of the transparent substrate; the electrodes are composed of

bus bars and a number of internal electrodes, and the internal electrodes are extended from the

bus bars to form interdigitated electrodes ; The

electrode is located on the transparent conductive layer and is in electrical contact with the transparent conductive layer, works at a

low voltage (≤12V), and reaches the expected temperature (90°C ~ 180°C). This invention is based on the test results at

room temperature and does not consider The shrinkage effect of different materials at low temperature affects the electrical

conductivity and electrothermal

instability of the material, so it is not suitable for use under low temperature conditions

Chinese application publication number: CN101704410A, titled "Nano superhydrophobic surface for aircraft anti-icing and deicing and its preparation method", the superhydrophobic surface constructed by hydrophobic

microstructure and hydrophobic nano-modified film realizes hydrophobic

microstructure and Connected to the upper surface of the aircraft

skin substrate, the secondary hydrophobic nano-membrane is located on the upper surface of the hydrophobic

microstructure, and is baked at a temperature of 80°C to 100°C for 1 to 5 hours to form a functional surface with superhydrophobic properties, although the invention has

Delay the time of freezing, but once the constructed surface freezes, it will increase the adhesion between the ice and the substrate, and the selected nano-film solidification temperature is relatively high. This method has complex design and difficult implementation

China Application Publication No.: CN105032731A, in the patent titled "Preparation Method of Energy-Saving and Anti-icing

Coating Composite with Super-hydrophobic

Coating and Heating

Coating", discloses an energy-saving anti-icing coating combined with super-hydrophobic coating and heating coating Ice coating preparation method, the heating coating is made of materials such as high temperature resistant conductive

adhesive,

electroplating conductive film, bonding fine

metal mesh or spreading electric

heating film, and spraying a waterproof protective coating with

thermal conductivity on the surface of the heating layer. The

superhydrophobic coating with

thermal conductivity is sprayed on the coating, and

aluminum foil is pasted on both ends as electrodes. This method has the advantages of both coating and electrothermal anti-icing. However, this method has the following disadvantages: (1) The heat-conducting particles use

Graphene, carbon nanotubes and other materials do not exert their electrical

conductivity and waste materials

(2) The heating coating is made of materials such as high-temperature-resistant conductive

adhesive and electroplated conductive film. The complexity of the process and the increase of the

interface layer bring difficulties in implementation, and the reduction of environmental applicability makes it difficult to achieve convenient and low-cost ship anti-icing performance.

Login to View More

Login to View More  Login to View More

Login to View More