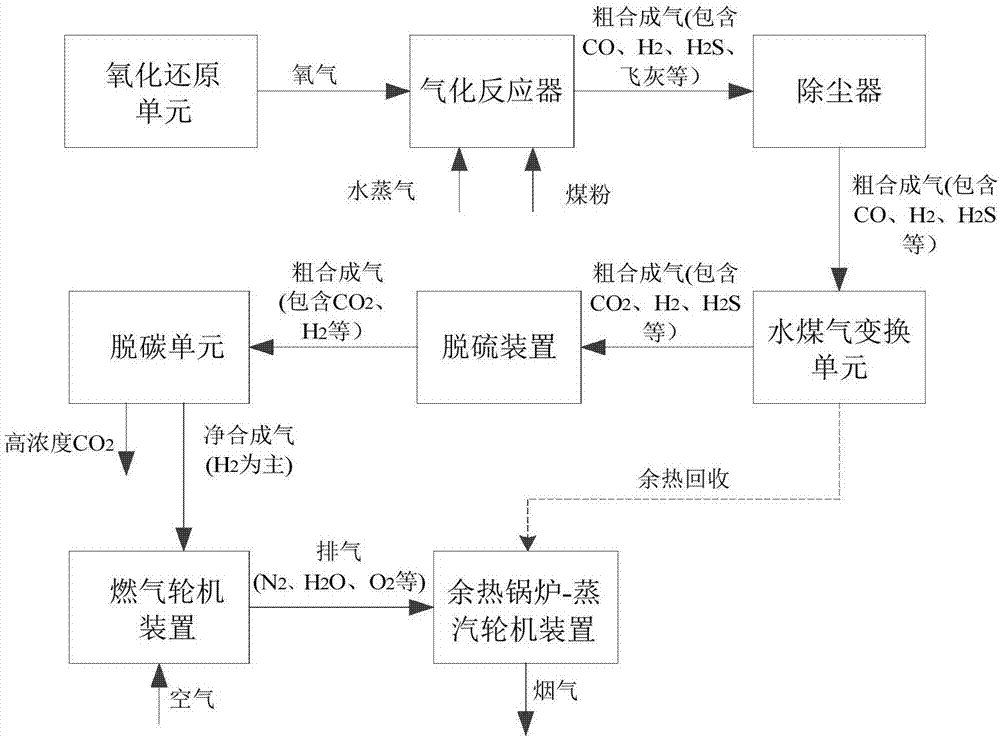

Power generation system based on chemical loop space division oxygen generation and CO2 gathering before combustion

A technology of power generation system and chemical chain, applied in chemical instruments and methods, inorganic chemistry, combined combustion mitigation, etc., can solve problems such as the decline of the efficiency of the whole plant, and achieve the effects of simple installation, reduction of installation size, and reduction of energy consumption for oxygen production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

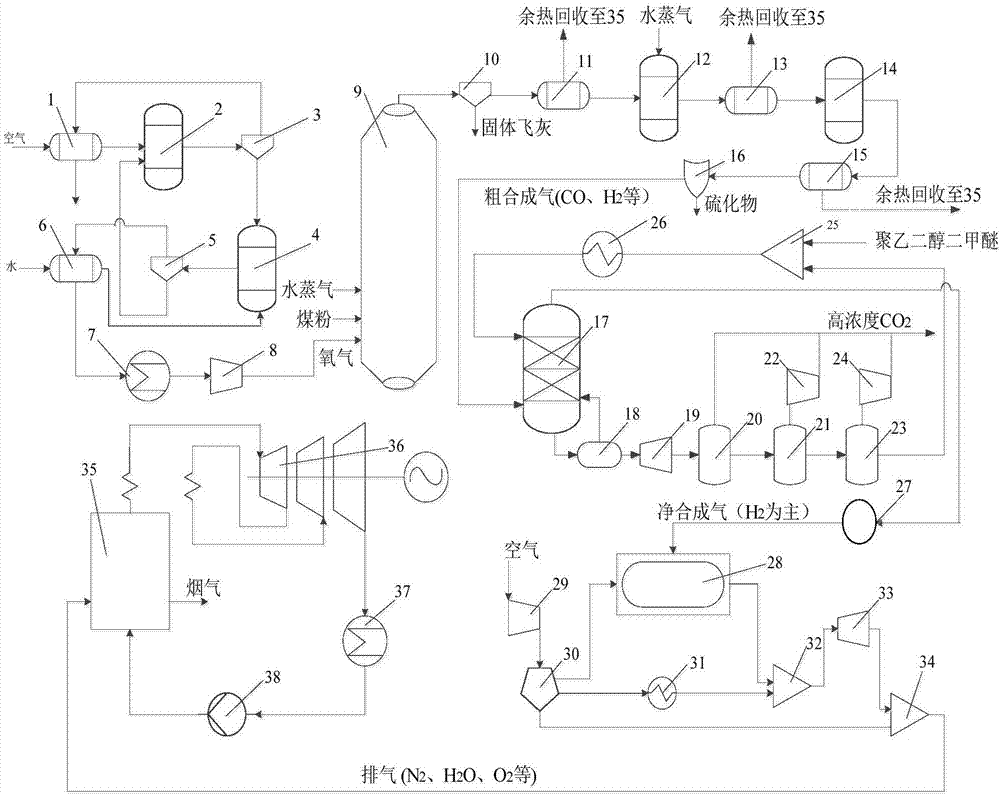

[0048] The oxygen carrier and air undergo an oxidation reaction in the oxidation reactor 2. After the reaction product is separated by the first gas-solid separator 3, the oxidized oxygen carrier enters the reduction reactor 4 to undergo a reduction reaction, and the separated gas enters the first gas-solid separator. The heat exchanger 1 preheats the incoming air; the pressure of the oxidation reactor 2 and the reduction reactor 4 is controlled at 1 bar; the product generated by the reduction reactor 4 is separated by the second gas-solid separator 5 again, The reduced oxygen carrier returns to the oxidation reactor 2 for reaction, and the separated gas enters the second heat exchanger 6, and the water in the second heat exchanger 6 is heated into water vapor, and the water vapor enters the reduction reactor, The gas from the second heat exchanger 6 passes through the first condenser 7 to obtain pure oxygen, and the pure oxygen enters the gasification reactor 9 through the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com