Centrifugal solid-phase enzyme cutting column, preparation method and application thereof

A spin column and solid-phase enzyme technology, applied in the biological field, can solve the problems of high enzyme cost, long use time, and large amount of protease, and achieve the effect of convenient separation, simple steps, and improved enzyme digestion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

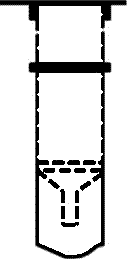

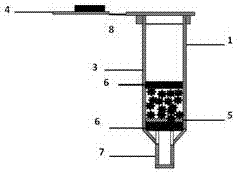

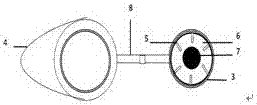

Image

Examples

Embodiment approach

[0084] A preferred embodiment of the preparation of the present invention utilizing trypsin to prepare a centrifugal solid-phase enzymatic digestion column is as follows:

[0085] 1. Vector activation

[0086] Select N-hydroxysuccinimide (NHS) modified agarose carrier sepharose4FF for activation

[0087] Take 1g of N-hydroxysuccinimide-modified agarose gel sepharose4FF, add 50ml of 1mM HCl, after swelling for 30min, wash the gel with 100ml of 1mM HCl for 6 times, and then wash with 100ml of ultrapure water

[0088] 2. The activated agarose gel sepharose4B with coupling buffer (0.1M NaHCO 3 , 0.8M NaCl, pH8.2) and washed 3 times. Add 20mol / L methylated trypsin, and couple at room temperature for 2 hours

[0089] 3. Wash the coupled trypsin-agarose carrier with 20mM, pH7.4 phosphate buffer PBS 3 times

[0090] 4. closed

[0091] Add 100mmol / L Tris.Cl pH8.0 to the coupled trypsin-agarose carrier, and react at room temperature for 2 hours

[0092] 5. Wash the blocked trypsin...

Embodiment 2

[0101] Example 2: Digestion of bovine lactoferrin by centrifugal trypsin solid-phase digestion column

[0102] 1. Take 10mg of bovine lactoferrin and prepare 10mg / ml lactoferrin solution with 100mM NH4HCO3, PH 8.0 buffer

[0103] 2. Take a centrifugal trypsin solid-phase enzymatic digestion column described in the present invention, cover the upper and lower plugs

[0104] 3. Take 0.1ml of the above-prepared bovine lactoferrin solution, add it to the above solution, and add 0.1ml of 6M Guanidine and 20ul of 1M DTT. Shake to mix for 5 seconds

[0105] 4. The above-mentioned spin column was reacted at 37°C for 30 minutes at a constant temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com