A strain of acid-tolerant Lactobacillus resistant to ethanol and high in lactic acid production and its application

A technology resistant to ethanol and lactobacilli, which is applied in the preparation of bacteria and alcoholic beverages, and methods based on microorganisms, can solve the problems of low ethanol tolerance, lactic acid bacteria increase, and the acidity of rice wine cannot be greatly improved, and achieve high Effects of Alcohol Tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: acid-resistant Lactobacillus strain characteristics

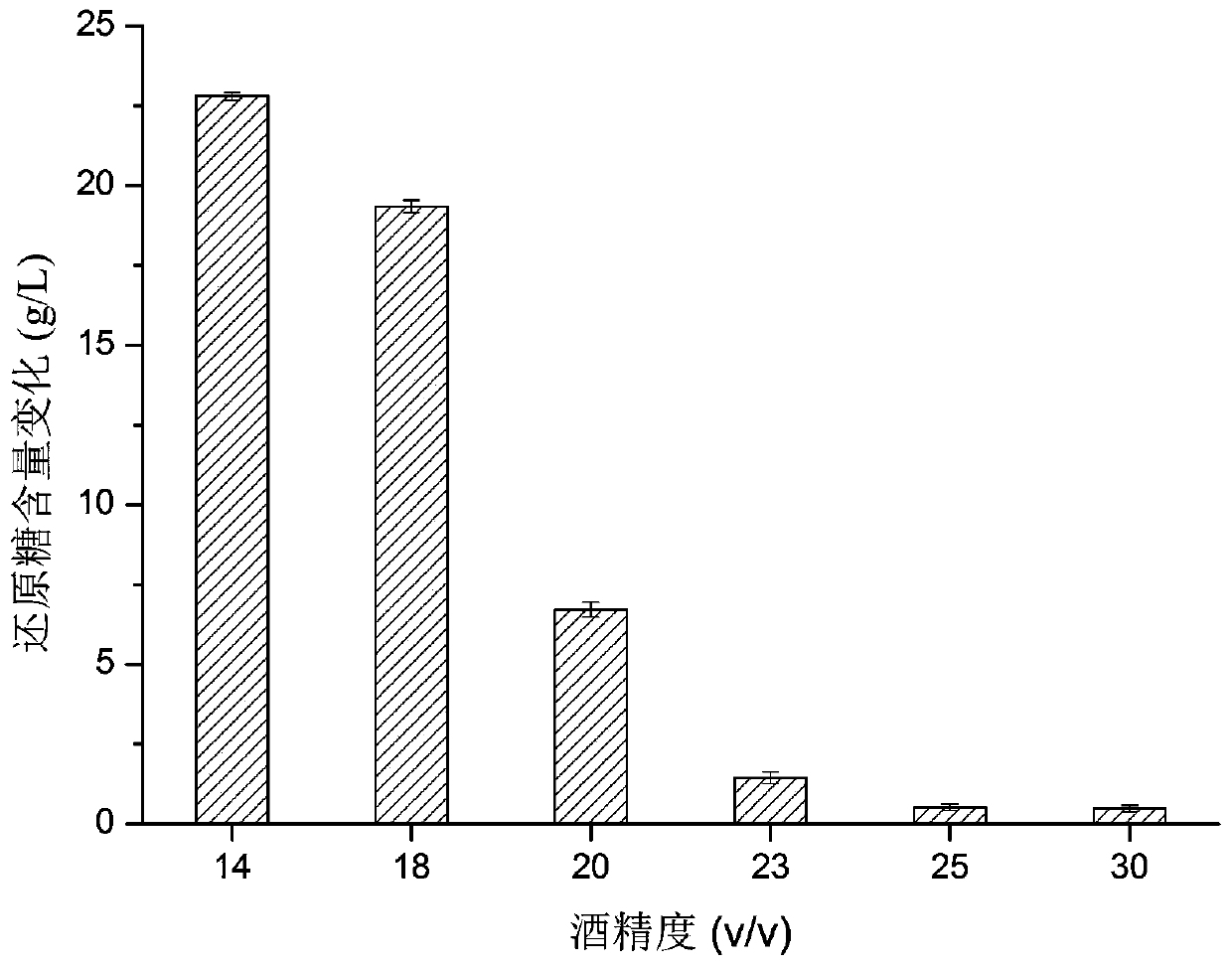

[0039] Lactobacillus acid-tolerant was inserted into liquid MRS-mevalonic acid medium with different alcohol concentrations according to the inoculation amount of 10%, and anaerobic static culture was carried out at 30°C for two weeks. The consumption of reducing sugar by microorganisms was as follows: figure 1 shown. It can be seen from the figure that the acid-tolerant Lactobacillus has a high alcohol tolerance, and there is still a slight growth phenomenon when the alcohol content reaches 23% (v / v).

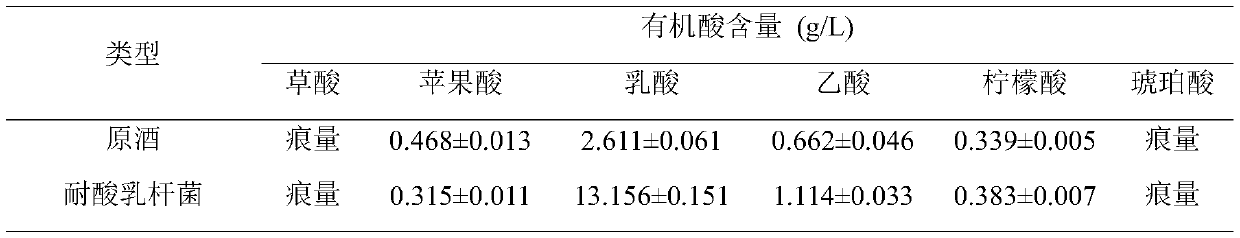

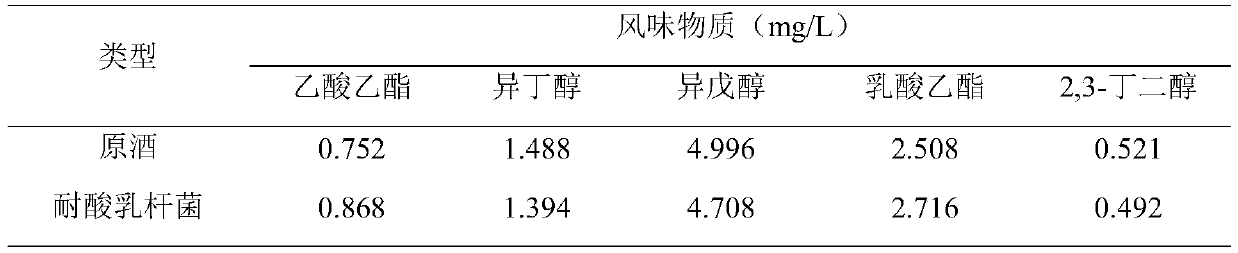

[0040] The acid-resistant Lactobacillus was inoculated into non-rancid rice wine samples according to 10% inoculation amount, and anaerobic static culture was carried out at 30°C for two weeks. Ultra-high performance liquid chromatography was used to detect the main organic acid content in the wine sample, and gas chromatography-mass spectrometry was used to detect the changes in the flavor substances ...

Embodiment 2

[0045] Embodiment 2: the preparation of acid-resistant Lactobacillus culture fluid

[0046] Bacteria culture in liquid test tubes: MRS-mevalonic acid medium was used, and anaerobic static culture was carried out at 30° C. for 3 to 5 days.

[0047]Preparation of seed medium: add glutinous rice to water and soak at 25°C for 2-3 days, drain and steam rice, add 4 times the amount of water according to the amount of glutinous rice, control the temperature at 50°C, add neutral protease at 8U / g glutinous rice, and stir Keep warm for 40 minutes, heat up to 60°C, add glucoamylase at 140U / g glutinous rice, stir evenly, keep warm and saccharify at 55°C for 4 hours, stir once every hour during this period, then filter to get the clear liquid, and pack it into a triangular flask at 115°C Sterilize for 20 minutes, cool to room temperature for later use.

[0048] Preparation of seed liquid: Inoculate the bacterium liquid in the above-mentioned triangular flask containing the seed culture li...

Embodiment 3

[0050] Embodiment 3: the fermentation process of rice wine with high acidity

[0051] Dosage of ingredients: based on 100kg of glutinous rice, 17kg of wheat koji, 7kg of rice wine yeast culture solution, 4kg of acid-tolerant Lactobacillus culture solution, and 180kg of water.

[0052] According to the ratio of raw materials, the specific steps of the production process are as follows:

[0053] (1) Rice soaking: After the rice is screened and removed, it is soaked in water for 24 hours, washed and drained;

[0054] (2) steamed rice;

[0055] (3) Cold rice: the steamed rice is cooled by a blower, and the temperature of the product in the tank is controlled to be 28°C;

[0056] (4) Pre-fermentation: add cooled rice, wheat koji, and feed water, and add 7 kg of yeast culture solution at the same time, stir evenly, and ferment for 4 days at a product temperature of 28°C;

[0057] (5) Post-fermentation: after the pre-fermentation ended, the fermented mash was transferred to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com