Bacillus subtilis strain for excreting nattokinase at high efficiency and preparation technology of high-purity nattokinase

A technology of Bacillus subtilis and nattokinase, applied in the direction of enzymes, peptidases, bacteria, etc., can solve the problem of not being able to express NK

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

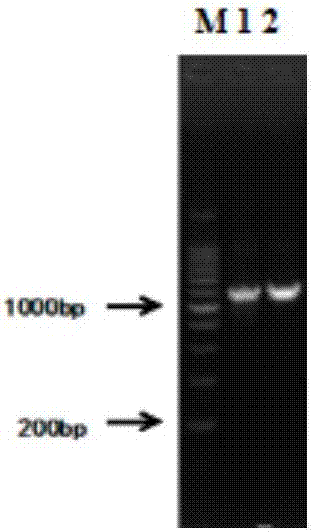

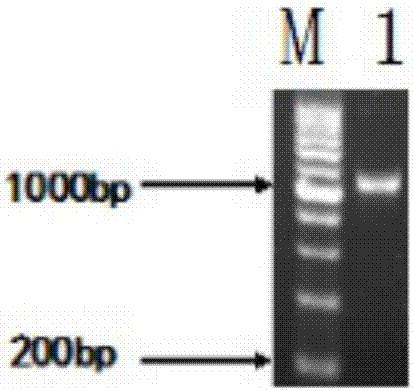

[0044] Step 1: Amplification and optimization of NK-aprN gene fragment

[0045] LB liquid medium: 10g / L peptone, 10g / L sodium chloride, 5g / L yeast extract.

[0046] LB solid medium: LB liquid medium, 15g / L agarose.

[0047] Amp solution: 100 mg / mL.

[0048] According to the nattokinase gene sequence included in GenBank (GI: 608796180), according to the codon preference of host bacteria B.subtitle (http: / / www.kazusa.or.jp / codon / cgi-bin / showcodon.cgi?species=1423) , using the biological software oligo to design primers (Table 1), amplify the aprN gene and optimize its first 30 amino acid codons. Primers were synthesized by Sangon Bioengineering Co., Ltd.

[0049] After the preserved B. subtilis 168 strain was activated, it was inoculated in LB medium according to the inoculum size of 2%, and cultured at 37° C. and 200 rpm for 12 hours. The cloning of the target gene adopts the method of over-lapping PCR, that is, the bacteria solution is used as the template for the first PC...

Embodiment 2

[0063] Inoculation: activate bacterial classification, prepare primary seed liquid and secondary seed liquid under 37 ℃, 200rpm culture condition, the secondary seed liquid that seed age is 12h is inoculated to fermentation medium according to 10% inoculum (chloramphenicol final concentration 5 μg / mL, antifoaming agent 0.01%). Fermentation medium (1L): glucose 28.5g, glycerol 57g, yeast extract 60g, dipicolinic acid 0.167g, NH 4 Cl 3g, K 2 HPO 4 ·3H 2 O 1g, MnSO 4 ·H 2 O 0.032g, FeSO 4 ·7H 2 O 0.05g, CoCl 2 ·6H 2 O 0.01g, ZnCl 2 0.01g, MgSO 4 ·7H 2 O 2g, CaCl 2 2H 2 O 5g, add water to 1000ml.

[0064] Fermentation: The stirring rate is initially set to 800rpm, and the ventilation rate is 12L / min. Set the parameters, control the temperature in the tank to 37°C, the dissolved oxygen to 30%, and the pH of the fermentation broth to 7.0, and adjust the stirring rate and ventilation according to the dissolved oxygen.

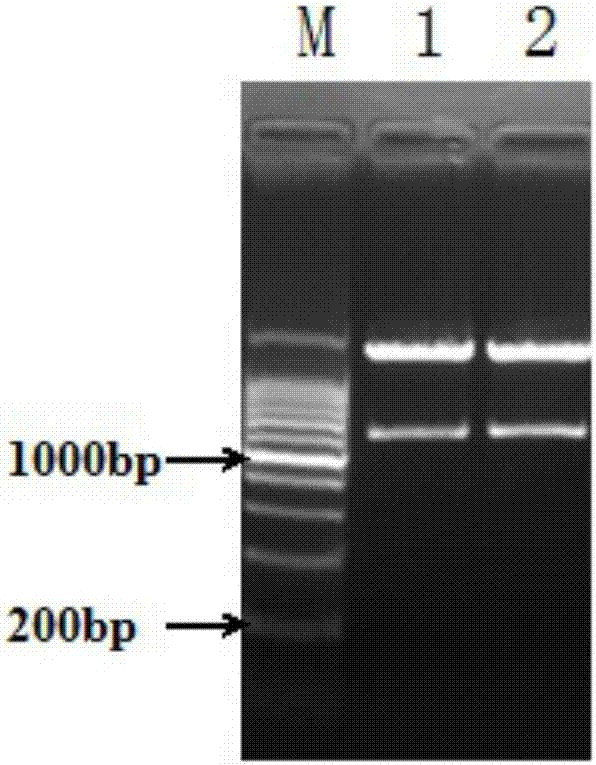

[0065] Protein induced expression: detection of...

Embodiment 3

[0070] The fermentation broth was refrigerated and centrifuged at 4°C and 9000r / m for 10min, and the supernatant was taken; the finely ground (NH 4 ) 2 SO 4 Add to the fermentation supernatant according to 20% saturation, store overnight at 4°C, centrifuge at 10,000r / m for 30min, discard the precipitate; continue to add ammonium sulfate to the fermentation supernatant to 60% saturation, store overnight at 4°C , centrifuged at 10000r / m for 30min, discarded the supernatant, and the recovery rate reached 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com