Modified paper making black liquid biological base film covering controlled-release fertilizer and preparation method thereof

A paper-making black liquor and controlled-release fertilizer technology, which is applied to layered/coated fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of high cost and poor treatment effect, achieve low equipment requirements, reduce surface energy, and improve The effect of nutrient release period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

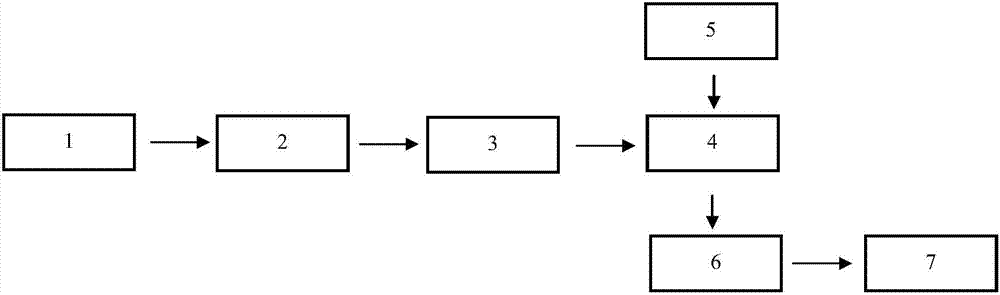

Method used

Image

Examples

Embodiment 1

[0026] Concentrate the papermaking black liquor, add dilute sulfuric acid to neutralize it, and dry it into powder. Weigh 200g of powder, add it to a reaction kettle with heating, stirring and condensing device, add 800g of liquefaction agent (polyethylene glycol and ethylene glycol are mixed uniformly in a weight ratio of 1:1 as a liquefaction agent), and stir , turn on the reactor and rapidly raise the temperature to 90°C, add concentrated sulfuric acid as a catalyst according to 3% of the weight ratio of the liquefaction agent, and continue to stir and react for 60 minutes to prepare a papermaking black liquor liquefaction product. Add 0.1% modifier (fluoroalkane, fluorosilane, perfluoro(alk)ene ether, fluoroalcohol, fluorine-containing acrylate and nano-silica, One or several of them such as nano-calcium carbonate), mixed uniformly and vibrated in ultrasonic for 30 minutes to obtain a modified liquefied product. Mix the modified liquefied product and the curing agent isoc...

Embodiment 2

[0028] Concentrate the papermaking black liquor, add dilute sulfuric acid to neutralize it, and dry it into powder. Weigh 200g of powder, add it to a reaction kettle with heating, stirring and condensing device, add 700g of liquefaction agent (polyethylene glycol, ethylene glycol, ethylene carbonate in a weight ratio of 1:1:1 and mix it uniformly as a liquefied liquefaction agent), under stirring conditions, open the reactor and rapidly heat up to 80°C, add concentrated sulfuric acid as a catalyst according to 4% of the weight ratio of the liquefaction agent, and continue stirring and reacting for 40 minutes to obtain a papermaking black liquor liquefaction product. Add 0.5% modifier (fluoroalkane, fluorosilane, perfluoro(alk)ene ether, fluoroalcohol, fluorine-containing acrylate and nano silicon dioxide, nano calcium carbonate to the liquefied product) One or several of them), mixed evenly, and vibrated in ultrasonic for 20 minutes to obtain a modified liquefied product. Mix...

Embodiment 3

[0030]Concentrate the papermaking black liquor, add dilute hydrochloric acid to neutralize it, and dry it into powder. Weigh 200g of powder, add it to a reaction kettle with heating, stirring and condensing device, add 800g of liquefaction agent (polyethylene glycol and glycerin are mixed uniformly in a weight ratio of 9:1 as a liquefaction agent), and under stirring conditions, open The temperature of the reaction kettle was rapidly raised to 120° C., and concentrated sulfuric acid was added as a catalyst according to the weight ratio of 3.5% of the liquefaction agent, and the stirring reaction was continued for 90 minutes to obtain a papermaking black liquor liquefaction product. Add 1% modifier (fluoroalkane, fluorosilane, perfluoro(alk)ene ether, fluoroalcohol, fluorine-containing acrylate and nano silicon dioxide, nano calcium carbonate to the liquefied product) One or several of them), mixed uniformly and vibrated in ultrasonic for 60 minutes to obtain a modified liquefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com