Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

A liquid crystal aligning agent and a specific technology, applied in the directions of liquid crystal materials, instruments, optics, etc., can solve the problems of difficult attenuation of accumulated charges, high volume resistivity of liquid crystal aligning films, and time-consuming removal of afterimages. Effects of small change, excellent charge accumulation characteristics, and excellent voltage retention characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0162] Hereinafter, the present invention will be described in more detail with examples given, but the present invention is not limited thereto. The abbreviations used in the following Examples and Comparative Examples are as follows.

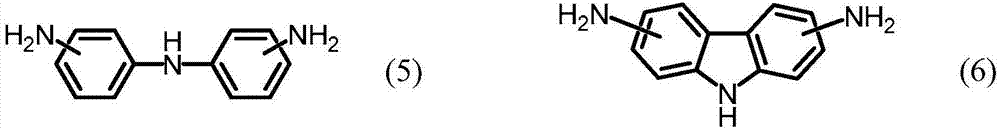

[0163] DA-1: 4,4'-Diaminodiphenylamine

[0164] DA-2: 4,4'-Diaminodiphenylmethane

[0165] DA-3: 1,5-bis(4-aminophenoxy)pentane

[0166] CA-1: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

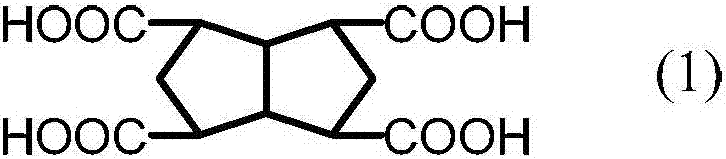

[0167] CA-2: Bicyclo[3,3,0]octane-2,4,6,8-tetracarboxylic dianhydride

[0168] CA-3: pyromellitic dianhydride

[0169] CA-4: 3,4-dicarboxy-1,2,3,4-tetrahydro-1-naphthalene succinic dianhydride

Synthetic example 1

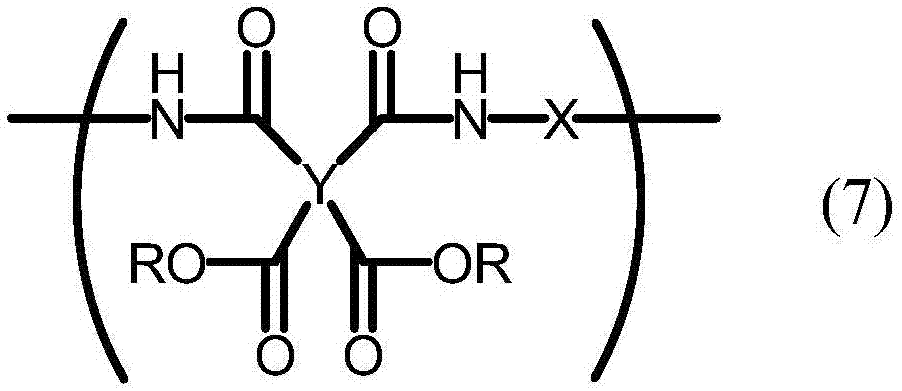

[0171] Add 7.97g (40.0mmol) of DA-1 and 1.98g (10.0mmol) of DA-2 in a 200ml four-necked flask with a stirring device and a nitrogen inlet tube, and then add 72.34g of N-methyl-2-pyrrolidone , stirring to dissolve while sending nitrogen gas. 6.86 g (35.0 mmol) of CA-1 was added, stirring this diamine solution, and it stirred at water temperature for 30 minutes. Then, 3.13 g (12.5 mmol) of CA-2 was added while stirring the solution, N-methyl-2-pyrrolidone was added so that the solid content concentration became 20% by mass, and the mixture was stirred at 50° C. in an oil bath under a nitrogen atmosphere. 3 hours. Next, N-methyl-2-pyrrolidone was added so that the solid content concentration might become 11 mass %, and it stirred overnight at 50 degreeC with the oil bath under nitrogen atmosphere, and obtained the solution of the polyamic acid. The viscosity at 25°C of the polyamic acid solution was confirmed to be 191 mPa·s with an E-type viscometer (manufactured by Toki Sangy...

Synthetic example 2

[0174] Add 7.49g (37.6mmol) of DA-1 and 1.86g (9.4mmol) of DA-2 in a 300ml four-necked flask with a stirring device and a nitrogen inlet tube, and then add 72.08g of N-methyl-2-pyrrolidone , stirring to dissolve while sending nitrogen gas. 2.12 g (10.8 mmol) of CA-1 was added, stirring this diamine solution, and it stirred at water temperature for 30 minutes. Then, 8.82 g (35.3 mmol) of CA-2 was added while stirring the solution, N-methyl-2-pyrrolidone was added so that the solid content concentration became 20% by mass, and the mixture was stirred at 50° C. in an oil bath under a nitrogen atmosphere. 3 hours. Next, N-methyl-2-pyrrolidone was added so that the solid content concentration might become 11 mass %, and it stirred overnight at 50 degreeC with the oil bath under nitrogen atmosphere, and obtained the solution of the polyamic acid. The viscosity at 25° C. of the polyamic acid solution was confirmed to be 207 mPa·s with an E-type viscometer (manufactured by Toki Sang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com