Wet-method chemical catalytic oxidation treatment method for processing VOCs organic exhaust gas and application thereof

A technology of organic waste gas and treatment process, which is applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of equipment loss and cost increase, achieve good treatment effect, fast response speed, and convenient upgrading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

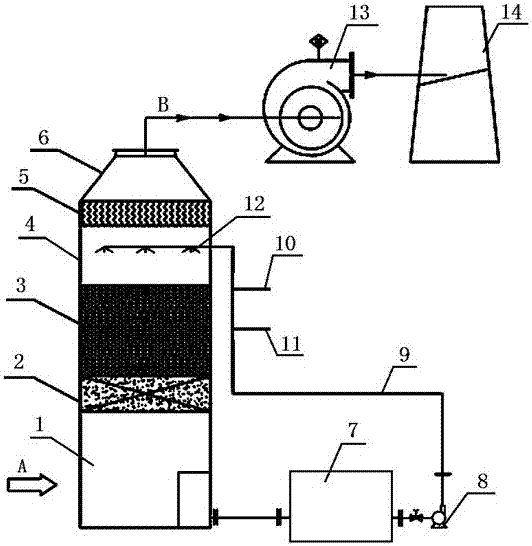

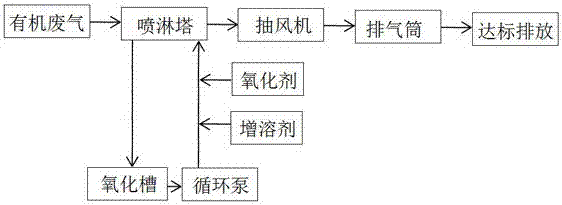

Method used

Image

Examples

Embodiment 2

[0034] The filler in the heterogeneous catalyst layer in this example is Mn / r-AL 2 o 3 , the thickness of the heterogeneous catalyst is 0.5m; the filler in the mass transfer packing layer is a Pall ring made of ceramics, and the thickness of the mass transfer packing layer is 0.5m. The catalyst works at normal temperature and pressure.

[0035] In this embodiment, the oxidant injected in the first step is 8% hydrogen peroxide by mass percentage, and the added amount (weight) of the hydrogen peroxide is 6 / 10,000 of the total amount of VOCs organic waste gas; the solubilizer injected in the first step is Cobaltous sulfate, the addition amount (weight) of cobaltous sulfate is 3 / 10,000 of the total waste gas.

[0036] A packaging and printing workshop: VOCs organic waste gas volume is 15000m 3 / h, VOCs organic waste gas before treatment is mainly benzene, toluene, xylene, styrene and other benzene substances, and its concentration is described by non-methane total hydrocarbons....

Embodiment 3

[0040] The filler in the heterogeneous catalyst layer in this example is Mn / r-AL 2 o 3 , the thickness of the heterogeneous catalyst is 0.3m; the filler in the mass transfer packing layer is a Raschig ring made of ABS, and the thickness of the mass transfer packing layer is 3m. The catalyst works at normal temperature and pressure.

[0041] In this embodiment, the oxidant injected in the first step is 10% hydrogen peroxide by mass percentage, and the added amount (weight) of the hydrogen peroxide is 10 / 10,000 of the total amount of VOCs organic waste gas; the solubilizer injected in the first step is Potassium bisulfite, the addition amount (weight) of potassium bisulfite is 7 / 10,000 of the total waste gas.

[0042] A packaging and printing workshop: the amount of VOCs organic waste gas is 15000m3 / h. Before treatment, VOCs organic waste gas is mainly chlorinated products such as trichloroethylene, chloroform, trichloroethane, etc., and its concentration is described by non-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com