Method of producing hexafluorobenzene from byproduct wastes of tetrachloroethylene

A technology of tetrachlorethylene and waste, applied in the field of production of hexafluorobenzene and methods from tetrachlorethylene by-product waste, can solve the problems of poor recovery, low catalytic efficiency, environmental damage, etc., to avoid difficult separation, phase Good capacitance, the effect of reducing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

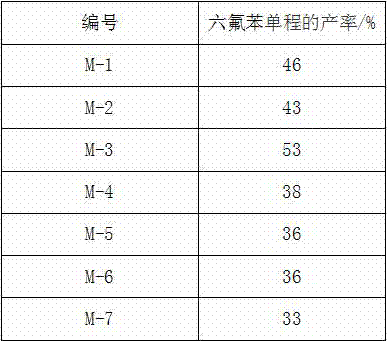

Examples

Embodiment 1

[0025] (1) Preparation of ionic liquid solvent: by weight, 100 parts of diphenyl ether, 0.03 parts of vitamin B12 (Vitamin B12), 0.2 parts of 1-methyl-1-propylpyrrolidine bis(trifluoromethanesulfonyl ) imine salt and 2 parts of 1-aminopropyl-3-methylimidazolium hexafluorophosphate were added to the reaction kettle and mixed at room temperature for 7 hours to obtain an ionic liquid solvent;

[0026] (2) Preparation of hexafluorobenzene:

[0027] By weight, with 100 parts of perchlorethylene by-product waste, containing 88 parts of hexachlorobenzene; 10 parts of octachlorotoluene; 2 parts of other impurities, 200 parts of dry KF, 500 parts of ionic liquid solvent, 7 parts of polystyrene The loaded quaternary phosphorus salt type resin catalyst is put into the reactor, and the system gradually heats up to react. As the reaction progresses, the products polyfluorobenzene and perfluorobenzene gasify, and the system pressure gradually increases. The reaction temperature is 420°C an...

Embodiment 2

[0031] (1) Preparation of ionic liquid solvent: by weight, 100 parts of tetraglyme, 0.01 part of vitamin B12 (VitaminB12), 0.05 part of 1-methyl-1-propylpyrrolidine bis(trifluoromethyl Sulfonyl)imide salt, 1 part of 1-aminopropyl-3-methylimidazolium hexafluorophosphate, was added to the reaction kettle and mixed at room temperature for 5 hours to prepare the ionic liquid solvent;

[0032] (2) Preparation of hexafluorobenzene:

[0033] By weight, with 100 parts of perchlorethylene by-product waste, containing 70 parts of hexachlorobenzene; 25 parts of octachlorotoluene; 5 parts of other impurities, 100 parts of dry KF, 300 parts of ionic liquid solvent, 5 parts of polystyrene The loaded quaternary phosphorus salt type resin catalyst is put into the reactor, and the system gradually heats up to react. As the reaction proceeds, the products polyfluorobenzene and perfluorobenzene gasify, and the system pressure gradually increases. The reaction temperature is 380°C and the reacti...

Embodiment 3

[0037] (1) Preparation of ionic liquid solvent: by weight, 100 parts of sulfolane, 0.1 part of vitamin B12 (Vitamin B12), 0.5 part of 1-methyl-1-propylpyrrolidine bis(trifluoromethanesulfonyl) Amine salt, 5 parts of 1-aminopropyl-3-methylimidazolium hexafluorophosphate, was added to the reaction kettle and mixed at room temperature for 10 hours to prepare the ionic liquid solvent;

[0038] (2) Preparation of hexafluorobenzene:

[0039]By weight, with 100 parts of perchlorethylene by-product waste, containing 94 parts of hexachlorobenzene; 5 parts of octachlorotoluene; 1 part of other impurities, 300 parts of dry KF, 800 parts of ionic liquid solvent, 15 parts of polystyrene The loaded quaternary phosphorus salt type resin catalyst is put into the reactor, and the system gradually heats up to react. As the reaction proceeds, the products polyfluorobenzene and perfluorobenzene gasify, and the system pressure gradually increases. The reaction temperature is 520°C and the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com