Diamond-shaped dodecahedron hollow potassium tannate nanoparticles and preparation method thereof

A rhombohedral dodecahedron and nanoparticle technology, applied in nanotechnology, nano-optics, nanotechnology, etc., can solve the problem of rare hollow potassium tannate nanoparticles, and achieve the effect of rich raw materials, simple preparation, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

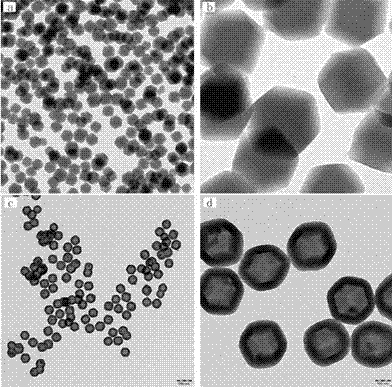

[0027] Preparation of Rhombohedral Dodecahedral Hollow Potassium Tannate Nanoparticles with a Scale of 200 nm and a Wall Thickness of 65 nm

[0028] First add 16 milliliters of ethylene glycol to a 50 milliliter test tube, add 20 milliliters of 3 mol / liter 2-methylimidazole ethylene glycol solution, 4 milliliters of 1 mol / liter zinc nitrate ethylene glycol solution, and stir evenly. After stirring evenly, place it in an ultrasonic pool at 40 degrees Celsius for 3 hours to obtain a milky white ZIF-8 nanoparticle colloidal solution. Centrifuge the obtained ZIF-8 nanoparticle colloidal solution with a centrifuge and centrifuge at a speed of 14,000 rpm. After 20 minutes, the colorless solution in the centrifuge tube was removed to obtain a white precipitate product, which was then ultrasonically cleaned 3 times with alcohol to obtain the following figure 2 a and 2b show ZIF-8 nanoparticles with a size of 200 nanometers, which are dissolved and dispersed in an aqueous solution for...

Embodiment 2

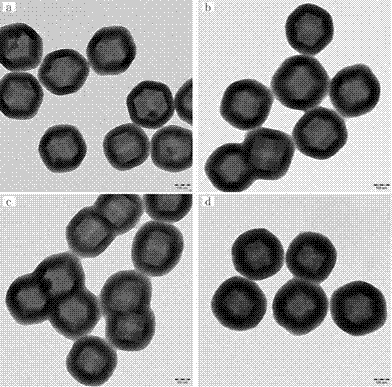

[0030] Preparation of Potassium Tannate Nanoparticles with Rhombic Dodecahedron with Different Wall Thickness under Certain Potassium Hydroxide Concentration

[0031] First, take 4 parts of 1 ml ZIF-8 colloid solution prepared in advance and add them to 4 2 ml centrifuge tubes respectively, and mark them as A, B, C, D, and then under the condition of rapid stirring (800 rpm) Add 0.03 ml of 1 mol / L potassium hydroxide aqueous solution and 0.05 ml of 0.1 mol / L tannic acid aqueous solution to centrifuge tube A; mol / L tannic acid aqueous solution; add 0.03 ml 1 mol / L potassium hydroxide aqueous solution, 0.15 ml 0.1 mol / L tannic acid aqueous solution to centrifuge tube C; add 0.03 ml 1 mol / L potassium hydroxide solution to centrifuge tube D Potassium hydroxide aqueous solution, 0.2 milliliters of 0.1 mol / liter tannic acid aqueous solution, wherein, the concentrations of potassium hydroxide and tannic acid in the A precursor are respectively 0.03 mol / liter and 0.005 mol / liter, and ...

Embodiment 3

[0033] Preparation of Potassium Tannate Nanoparticles with Rhombic Dodecahedron with Different Wall Thickness under Certain Conditions of Tannin Concentration

[0034] First, take 4 parts of 1 ml ZIF-8 colloid solution prepared in advance and add them to 4 2 ml centrifuge tubes respectively, and mark them as A, B, C, D, and then under the condition of rapid stirring (800 rpm) Add 0.01 ml of 1 mol / L potassium hydroxide aqueous solution and 0.1 ml of 0.1 mol / L tannic acid aqueous solution to centrifuge tube A; mol / L tannic acid aqueous solution; add 0.03 ml 1 mol / L potassium hydroxide aqueous solution, 0.1 ml 0.1 mol / L tannic acid aqueous solution to centrifuge tube C; add 0.04 ml 1 mol / L potassium hydroxide solution to centrifuge tube D Potassium hydroxide aqueous solution, 0.1 milliliter of 0.1 mol / liter tannic acid aqueous solution, wherein, the concentrations of potassium hydroxide and tannic acid in the A precursor are respectively 0.01 mol / liter and 0.01 mol / liter, and in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com