Citric acid-modified cyclodextrin crosslinking chitosan porous adsorption material, and preparation and application of same

A technology of porous adsorption material and cross-linked chitosan, which can be used in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc. It can solve the problem of low grafting rate, increase water solubility and reduce crystallinity , the effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

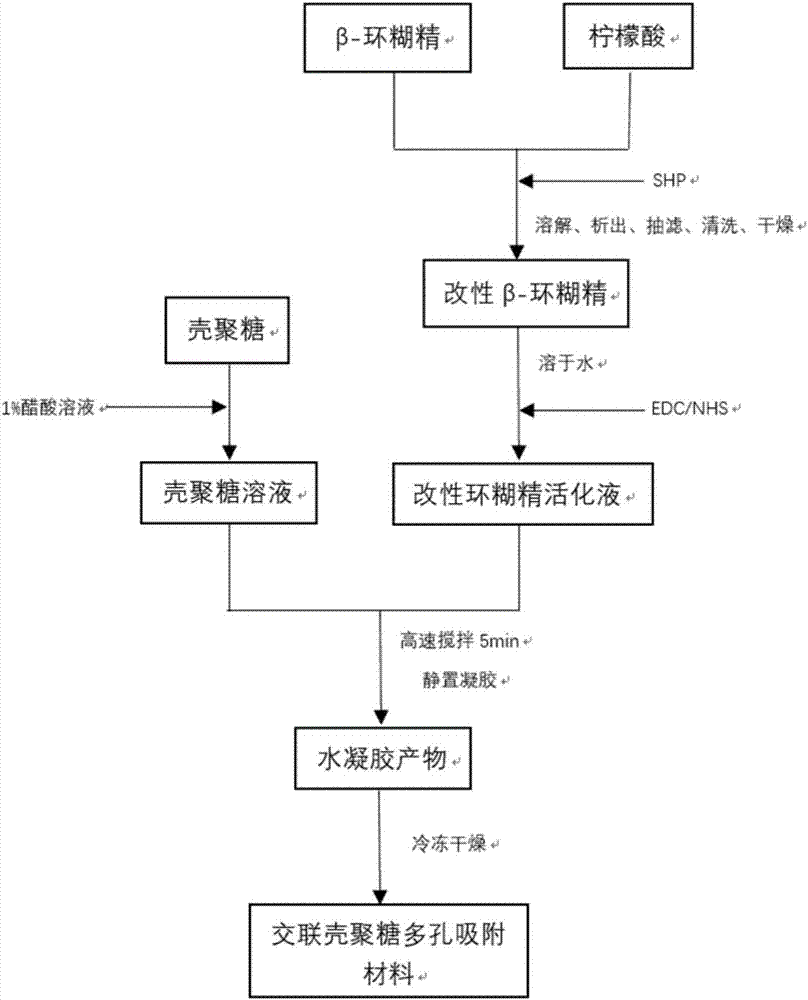

Method used

Image

Examples

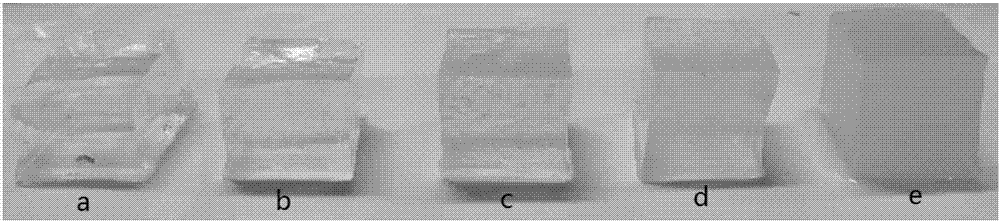

Embodiment 1

[0045] Accurately weigh 12.6g of citric acid, and dissolve 2.52g of sodium hypophosphite in 12mL of deionized water. After complete dissolution, 11.35 g of β-cyclodextrin was added, and the temperature was raised to 80° C., the cyclodextrin was dissolved, and a non-transparent solution was obtained. It was pre-baked at 100°C for 1 hour and then baked at 120°C for 5 hours in a blast-type constant temperature drying oven. After the reaction, add 30-50mL deionized water to dissolve, then slowly add it dropwise into absolute ethanol, precipitate out, and wash repeatedly with absolute ethanol 5-6 times, then dry the precipitate at 55°C to constant weight, To obtain citric acid modified cyclodextrin (such as figure 1 , The IR of the citric acid modified cyclodextrin has an obvious carbonyl absorption peak of the ester bond at 1722cm-1, indicating that the chemical modification is successful).

[0046] Accurately weigh 0.8g of modified cyclodextrin and dissolve it in 20mL of deion...

Embodiment 2

[0048] Accurately weigh 12.6g of citric acid, and dissolve 2.52g of sodium hypophosphite in 12mL of deionized water. After complete dissolution, 11.35 g of β-cyclodextrin was added, and the temperature was raised to 80° C., the cyclodextrin was dissolved, and a non-transparent solution was obtained. It was pre-baked at 100°C for 1 hour and then baked at 120°C for 5 hours in a blast-type constant temperature drying oven. After the reaction, add 30-50mL deionized water to dissolve, then slowly add it dropwise into absolute ethanol, precipitate out, and wash repeatedly with absolute ethanol 5-6 times, then dry the precipitate at 55°C to constant weight, A citric acid modified cyclodextrin was obtained.

[0049] Accurately weigh 1.6g of modified cyclodextrin and dissolve it in 40mL of deionized water, add 2.36g of EDC and 1.41g of NHS and stir for activation at room temperature for 30min. Then add the activation solution into 213.3mL of 3%wt chitosan solution, stir rapidly for 5...

Embodiment 3

[0051] Accurately weigh 12.6g of citric acid, and dissolve 2.52g of sodium hypophosphite in 12mL of deionized water. After complete dissolution, 11.35 g of β-cyclodextrin was added, and the temperature was raised to 80° C., the cyclodextrin was dissolved, and a non-transparent solution was obtained. It was pre-baked at 100°C for 1 hour and then baked at 120°C for 5 hours in a blast-type constant temperature drying oven. After the reaction, add 30-50mL deionized water to dissolve, then slowly add it dropwise into absolute ethanol, precipitate out, and wash repeatedly with absolute ethanol 5-6 times, then dry the precipitate at 55°C to constant weight, A citric acid modified cyclodextrin was obtained.

[0052] Accurately weigh 2.4g of modified cyclodextrin and dissolve in 60mL of deionized water, add 3.54g of EDC and 2.11g of NHS and stir at room temperature for 30min to activate. Then the activation solution was added to 186.7 mL of 3% wt chitosan solution, stirred rapidly fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com