Gold film covered high-density nano needle point array and application thereof

A high-density, array technology, applied in the direction of measuring devices, instruments, and material analysis through optical means, can solve the problems of difficult rapid trace detection of triphenylphosphine concentration, responsible preparation method, poor selectivity, etc. , to achieve the effect of clean surface, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

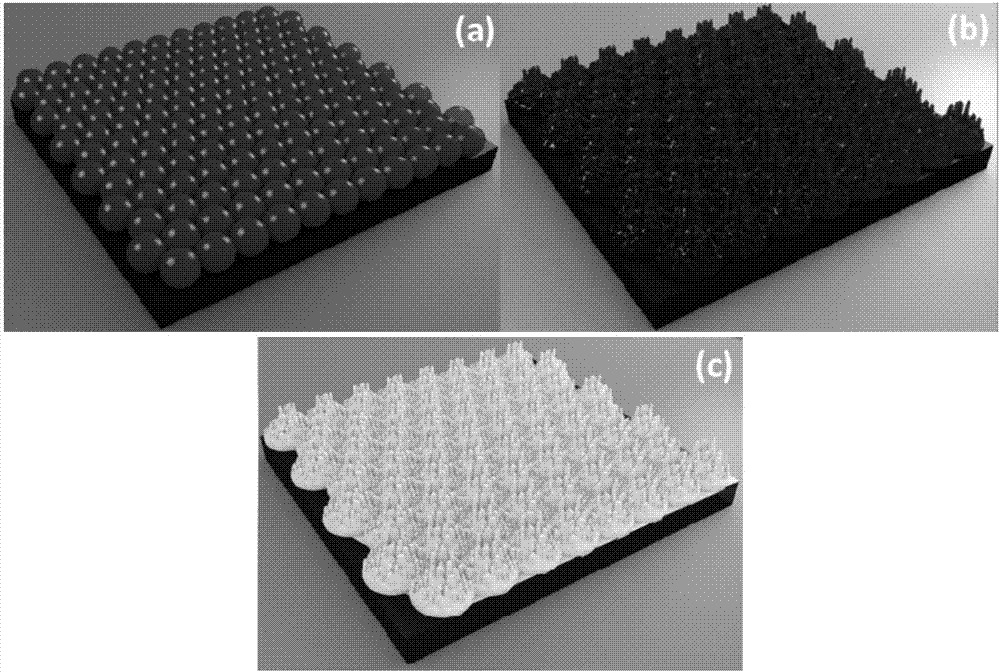

[0030] A high-density nano needle tip array covered by a gold film, the preparation method of which comprises the following steps:

[0031] Step A, preparing a closely arranged single-layer polystyrene colloidal crystal array on a glass substrate, thereby obtaining a glass-substrate single-layer polystyrene colloidal crystal array.

[0032] Specifically, the preparation of a tightly arranged single-layer polystyrene colloidal crystal array on a glass substrate includes the following steps:

[0033] Step A1, put the glass substrate (for example: the glass substrate can be a glass sheet made of ordinary glass) into acetone, ethanol, the first mixed solution, and deionized water for ultrasonic cleaning, and then dry the cleaned glass substrate dry treatment, and then placed in an ultraviolet ozone cleaning machine for 10-40 minutes of irradiation, so as to obtain a glass substrate with a hydrophilic surface. Wherein, the first mixed liquid is formed by mixing concentrated sulfuric...

Embodiment 1

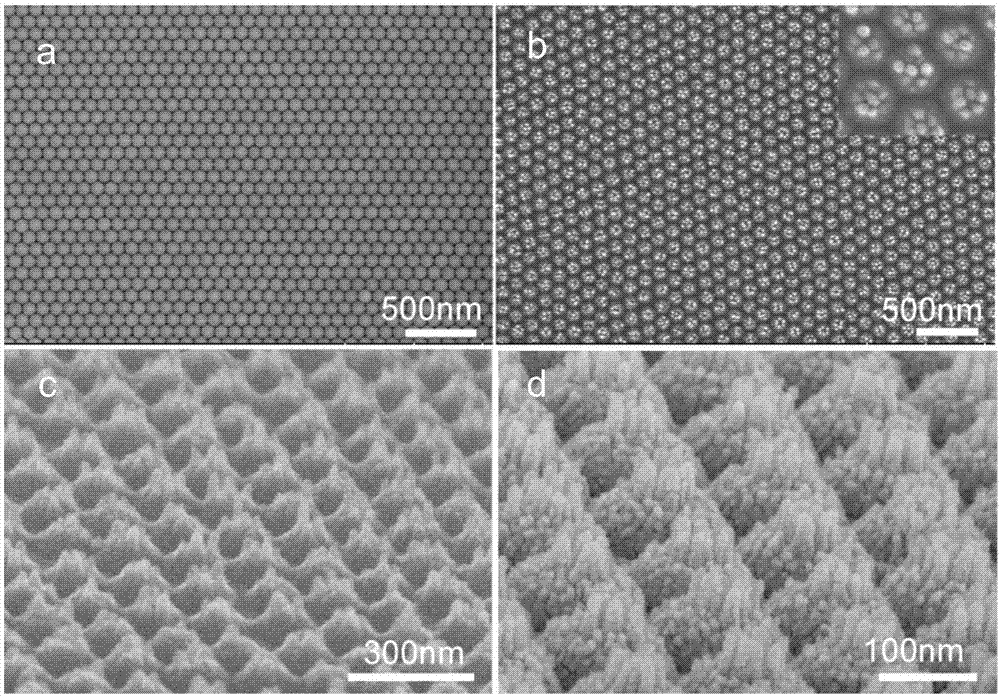

[0048] A high-density nano-tip array covered by a gold film is prepared by the following steps:

[0049] Step a, the glass substrate (the glass substrate is a common glass sheet) is put into acetone, ethanol, and the first mixed solution successively (the first mixed solution is composed of concentrated sulfuric acid with a mass concentration of 1.84g / ml and a mass concentration of 1.1g / ml ml of hydrogen peroxide according to the volume ratio of 3:1), ultrasonic cleaning in deionized water, ultrasonic cleaning in each liquid for 40 minutes, and then drying the cleaned glass substrate at a drying temperature of 120°C, The drying time is 20 minutes; after the water on the glass substrate is completely evaporated, place the glass substrate in an ultraviolet ozone cleaning machine for 10-40 minutes of irradiation, so as to obtain a glass substrate with a hydrophilic surface.

[0050] Step b, take 50 microliters of polystyrene colloidal sphere suspension (2.5wt.%) with a colloidal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com