Preparation method of self-assembled lysozyme multilayer membrane with antibacterial property and biocompatibility

A biocompatible, lysozyme technology, applied in coatings, pharmaceutical formulations, drug delivery, etc., to achieve the effect of simple and easy method, reduced damage, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

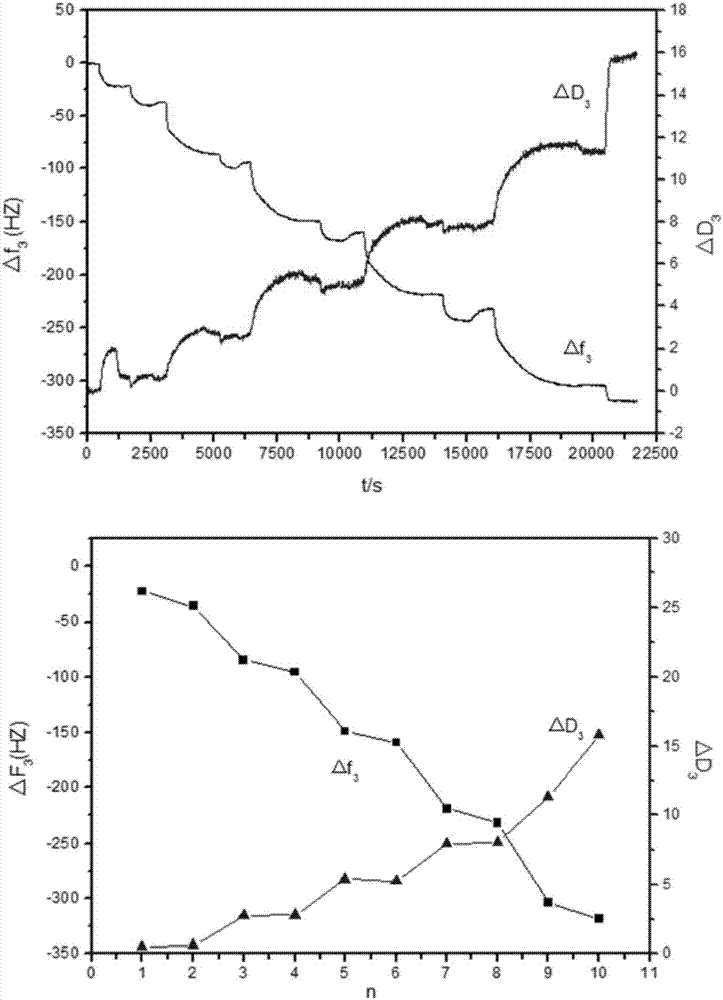

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] (1) Substrate pretreatment of self-assembled membrane

[0033] After surface treatment, the glass is immersed in a polyethyleneimine solution with a concentration of 0.01mg / mL to self-assemble to form the bottom layer;

[0034] (2) Preparation of plant polyphenol aqueous solution

[0035] Prepare 10ml of 10mM HEPES buffer solution, pH=4, add ascorbic acid to 5mM and tannic acid (TA) to 0.01mg / ml in turn, stir until completely dissolved, and prepare a tannic acid aqueous solution with a concentration of 0.01mg / mL;

[0036] (3) Preparation of protein aqueous solution

[0037] Configure 10ml of 10mM HEPES buffer solution, adjust the pH to 4, add 5mM to ascorbic acid and lysozyme to 0.01mg / ml in sequence, stir until completely dissolved, and prepare a lysozyme aqueous solution with a concentration of 0.01mg / mL;

[0038] (4) Preparation of self-assembled multilayer films

[0039] Immerse the substrate treated in step...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] (1) Substrate pretreatment of self-assembled membrane

[0044] After surface treatment, the glass is immersed in a polyethyleneimine solution with a concentration of 1 mg / mL to self-assemble to form the bottom layer;

[0045] (2) Preparation of plant polyphenol aqueous solution

[0046] Prepare 50mM HEPES buffer solution, pH=6, sequentially add sodium chloride to 0.15mol / l, ascorbic acid to 10mM and tannic acid (TA) to 1mg / mL, stir until completely dissolved, and prepare a single solution with a concentration of 1mg / mL. Nitric acid aqueous solution;

[0047] (3) Preparation of protein aqueous solution

[0048]Prepare 50mM HEPES buffer solution, pH=6, sequentially add sodium chloride to 0.15mol / l, ascorbic acid to 10mM and lysozyme to 1mg / mL, stir until completely dissolved, and prepare a lysozyme aqueous solution with a concentration of 1mg / mL;

[0049] (4) Preparation of self-assembled multilayer films

[0050...

Embodiment 3

[0052] This embodiment includes the following steps:

[0053] (1) Substrate pretreatment of self-assembled membrane

[0054] After surface treatment, the glass is immersed in a polyethyleneimine solution with a concentration of 10 mg / mL to self-assemble to form the bottom layer;

[0055] (2) Preparation of tannic acid aqueous solution

[0056] Prepare 50mM HEPES buffer solution, pH=8, sequentially add sodium chloride to 0.5mol / l, ascorbic acid to 50mM and tannic acid (TA) to 10mg / ml, stir until completely dissolved, and configure a single solution with a concentration of 10mg / mL Nitric acid aqueous solution;

[0057] (3) Preparation of lysozyme aqueous solution

[0058] Prepare 50mM HEPES buffer solution, pH=8, add sodium chloride to 0.5mol / l, ascorbic acid to 50mM and lysozyme to 10mg / ml in sequence, stir until completely dissolved, and prepare a lysozyme aqueous solution with a concentration of 10mg / mL;

[0059] (4) Preparation of self-assembled multilayer films

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com