Preparation method of modified activated carbon from peanut shells and application thereof

A peanut shell and activated carbon technology, which is applied in the field of material preparation and pollutant treatment, can solve problems such as no industrial use value and environmental pollution, and achieve the effects of improving processing capacity, reducing costs, and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

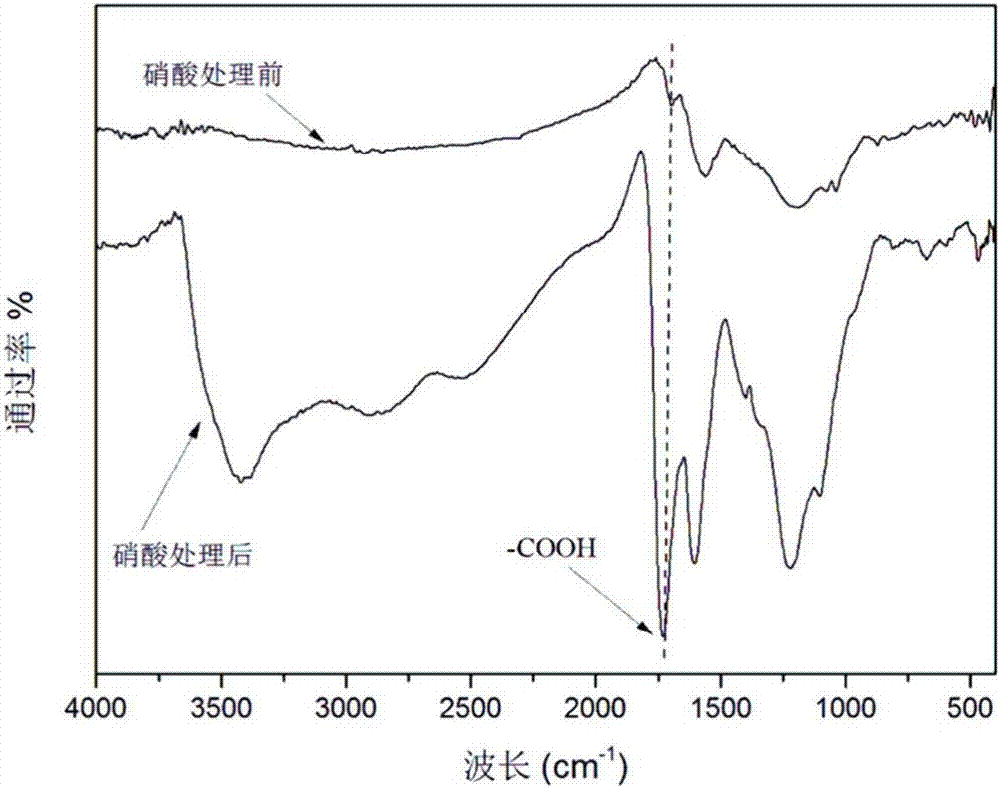

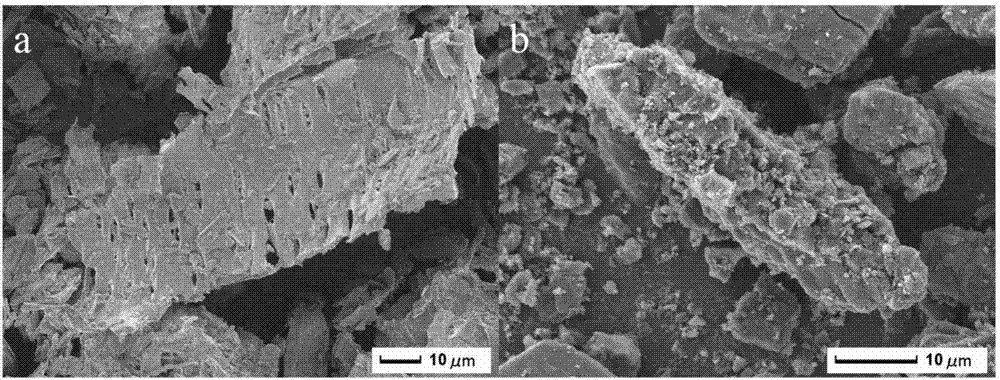

[0028] 1. Preparation of Peanut Shell Modified Activated Carbon

[0029] (1) Wash the peanut shells with water, dry them at 100°C for 24 hours, crush them and pass them through a 60-mesh sieve to obtain peanut shell powder.

[0030] (2) Weigh 5.0 g of peanut shell powder, add it to 100 mL of 5% zinc chloride solution, heat in a water bath at 50° C. for 3 h, and finally vacuum-dry at 100° C. for 24 h, then grind to obtain the peanut shell active material.

[0031] (3) Take 5.0 g of peanut shell active raw materials and place them in a tube furnace, and pass nitrogen gas at a rate of 50 mL / min for 10 min to remove the air in the tube. Then, under the protection of nitrogen, the temperature was raised to 800°C at a rate of 3°C / min, and kept for 30min, then the heating was stopped and nitrogen was continuously passed in to cool to room temperature, and then washed and dried.

[0032] (4) Add 2.0 g of the material obtained in step (3) into 100 mL of 2 mol / L hydrochloric acid solut...

Embodiment 2

[0037] 1. Preparation of Peanut Shell Modified Activated Carbon

[0038] (1) Wash the peanut shells with water, dry them at 120° C. for 12 hours, crush them and pass them through a 60-mesh sieve to obtain peanut shell powder.

[0039] (2) Weigh 5.0 g of peanut shell powder, add it to 100 mL of 20% zinc chloride solution, heat in a water bath at 70° C. for 1 h, and finally vacuum-dry at 120° C. for 12 h, then grind to obtain the peanut shell active material.

[0040] (3) Take 5.0 g of peanut shell active raw materials and place them in a tube furnace, and pass nitrogen gas at a rate of 50 mL / min for 10 min to remove the air in the tube. Then, under the protection of nitrogen, the temperature was raised to 600°C at a rate of 3°C / min, and kept for 120min, then the heating was stopped and nitrogen was passed continuously to cool to room temperature, and then washed and dried.

[0041] (4) Add 2.0 g of the material obtained in step (3) into 100 mL of hydrochloric acid solution wit...

Embodiment 3

[0046] 1. Preparation of Peanut Shell Modified Activated Carbon

[0047] (1) Wash the peanut shells with water, dry at 100°C for 24 hours, crush them and pass through a 60-mesh sieve to obtain peanut shell powder

[0048] (2) Weigh 5.0 g of peanut shell powder, add it to 100 mL of 5% potassium hydroxide solution, heat in a water bath at 50° C. for 3 h, and finally vacuum-dry at 100° C. for 24 h, then grind to obtain the peanut shell active material.

[0049] (3) Take 5.0 g of peanut shell active material and place it in a tube furnace, and pass nitrogen gas at a rate of 50 mL / min for 10 min to remove the air in the tube. Then, under the protection of nitrogen, the temperature was raised to 800°C at a rate of 3°C / min, and kept for 30min, then the heating was stopped and nitrogen gas was continuously passed in to cool to room temperature, and washed and dried.

[0050] (4) Add 2.0 g of the material obtained in step (3) into 100 mL of 2 mol / L hydrochloric acid solution, heat in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com