Method for preparing graphene through arc-plasma continuous stripping

A technology of arc plasma and graphene, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of continuous and stable large-scale production, small two-dimensional size area, graphite lattice damage, etc., and achieve continuous Efficient preparation, low preparation cost and high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

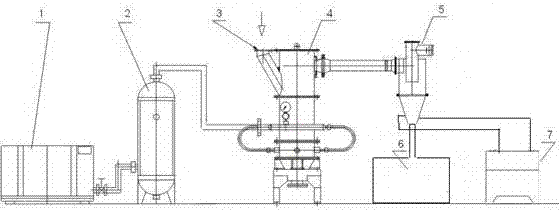

[0024] A method for preparing graphene material by arc plasma continuous exfoliation. Firstly, graphite is pulverized and exfoliated into graphite powder less than 5 μm through airflow milling, and then the graphite is accelerated through a cyclone by high-pressure airflow. At the nozzle of the cyclone, the inner wall of the nozzle and the Arc plasma is generated between the cathodes, and the multilayer graphite flow is instantly stripped into graphene under the action of the arc plasma jet, and completely dispersed graphene is obtained through the liquid nitrogen pool. The schematic diagram of the equipment is as follows figure 1 . The crushed graphite enters the cyclone and is driven by high-pressure gas to accelerate spirally, and it is ejected from the lower nozzle. The lower nozzle is an arc plasma anode with an inner diameter of about 20mm. The center of the lower nozzle is equipped with an arc plasma cathode. The cyclone is equipped with high-pressure water cooling. sys...

Embodiment 2

[0031] A method for preparing graphene material by arc plasma continuous exfoliation. Firstly, graphite is pulverized and exfoliated into graphite powder less than 5 μm through airflow milling, and then the graphite is accelerated through a cyclone by high-pressure airflow. At the nozzle of the cyclone, the inner wall of the nozzle and the Arc plasma is generated between the cathodes, and the multilayer graphite flow is instantly stripped into graphene under the action of the plasma jet, and completely dispersed graphene is obtained by cold extraction in a liquid nitrogen heat exchanger. The schematic diagram of the equipment is as follows figure 1 . The detailed operation steps include turning on the liquid nitrogen device, turning on the arc discharge, graphite crushing, graphene exfoliation and sample collection.

[0032] Among them, the jet mill pressure is controlled at 150KPa, and the gas velocity is controlled at 15m / s.

[0033] Among them, the cyclone outlet velocity ...

Embodiment 3

[0037]A method for preparing graphene material by arc plasma continuous exfoliation. Firstly, graphite is pulverized and exfoliated into graphite powder less than 5 μm through airflow milling, and then the graphite is accelerated through a cyclone by high-pressure airflow. At the nozzle of the cyclone, the inner wall of the nozzle and the Arc plasma is generated between the cathodes, and the multilayer graphite flow is instantly stripped into graphene under the action of the plasma jet, and completely dispersed graphene is obtained by cold extraction in a liquid nitrogen heat exchanger. The schematic diagram of the equipment is as follows figure 1 . The detailed operation steps include turning on the liquid nitrogen device, turning on the arc discharge, graphite crushing, graphene exfoliation and sample collection.

[0038] Among them, the jet mill pressure is controlled at 120 KPa, and the gas velocity is controlled at 20m / s.

[0039] Among them, the cyclone outlet velocity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com