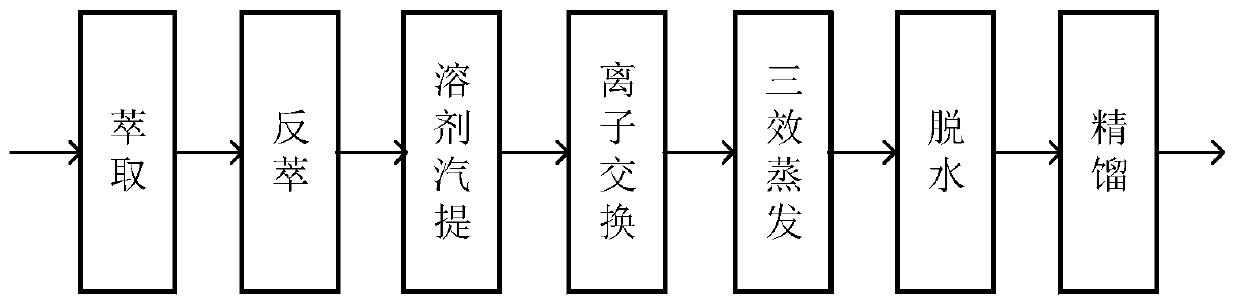

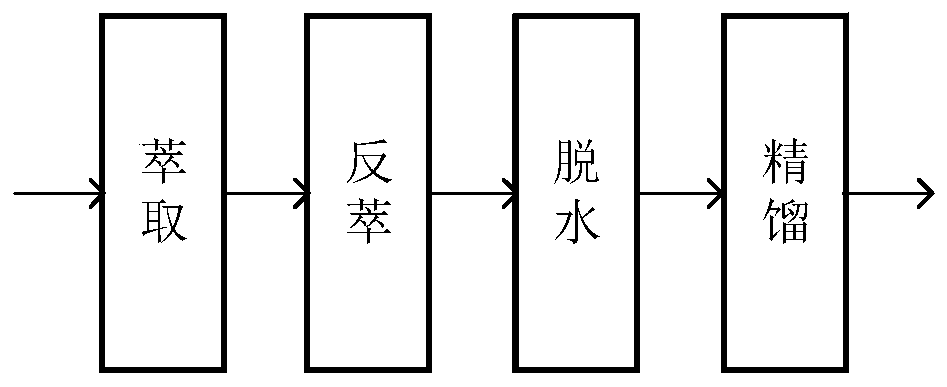

A kind of separation and purification process of caprolactam

A technology of caprolactam and process, which is applied in the field of chemical separation, can solve the problems of increasing equipment and increasing process complexity, and achieve the effects of reducing load, suppressing the content of polar impurities, and optimizing the extraction operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

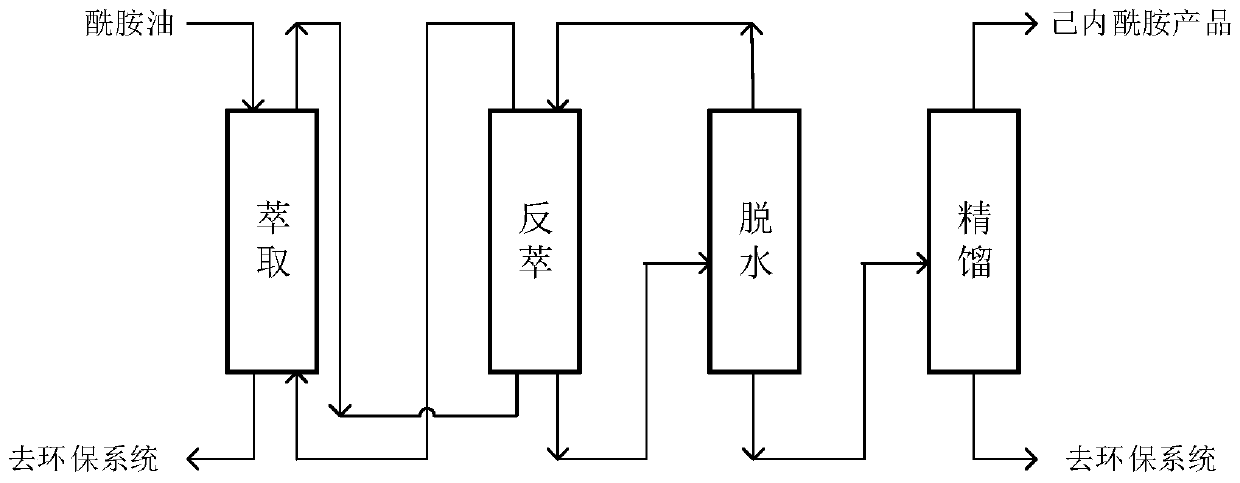

Method used

Image

Examples

Embodiment 1

[0031] Example 1: The extraction tower uses a turntable tower, and the back extraction tower uses a pulse sieve tray tower. The extractant is a mixed solution prepared with a mass ratio of toluene and n-octane of 3:1. For the extraction tower, the feed flow rate of amide oil is 10t / h, the feed flow rate of extractant is 40t / h, and the rotating speed of the turntable is 18 revolutions per minute. For the stripping tower, the feed flow rate of water is 6t / h, the pulse amplitude is 2cm, and the pulse frequency is 60 Hz. The dehydration tower uses a float valve tower and operates under normal pressure. The temperature of the bottom of the tower is 120°C and the temperature of the top of the tower is 95°C. The crude caprolactam rectification tower uses a packed tower, operating at 2.2 kPa (absolute pressure), and the bottom temperature of the tower is 145°C. The concentration of caprolactam in the loaded extractant discharged from the extraction tower is 14.8%wt. The caprolactam c...

Embodiment 2

[0032] Example 2: The extraction tower uses a pulse sieve plate tower, and the reverse extraction tower uses a pulse sieve plate tower. The extractant is a mixed solution prepared with a mass ratio of toluene and n-octane 2:1. For the extraction tower, the feed flow rate of amide oil is 10t / h, the feed flow rate of extractant is 60t / h, and the rotating speed of the turntable is 20 revolutions per minute. For the stripping tower, the water feed flow rate is 5.2t / h, the pulse amplitude is 2cm, and the pulse frequency is 60 Hz. The dehydration tower uses a float valve tower and operates under normal pressure. The temperature of the bottom of the tower is 120°C and the temperature of the top of the tower is 95°C. The crude caprolactam rectification tower uses a packed tower, operating at 2.0kPa (absolute pressure), and the temperature of the tower bottom is 140°C. The concentration of caprolactam in the loaded extractant discharged from the extraction tower is 9.8%wt. The caprola...

Embodiment 3

[0033] Example 3: The extraction tower uses a turntable tower, and the reverse extraction tower uses a turntable tower, and the extractant is a mixed solution prepared with a mass ratio of toluene and n-octane 1:1. For the extraction tower, the feed flow of amide oil is 10t / h, the feed flow of extractant is 80t / h, and the rotating speed of the turntable is 22 revolutions per minute. For the stripping tower, the water feed flow rate is 5t / h, the pulse amplitude is 2cm, and the pulse frequency is 60 Hz. The dehydration tower uses a float valve tower and operates under normal pressure. The temperature of the bottom of the tower is 120°C and the temperature of the top of the tower is 95°C. The crude caprolactam rectification tower uses a packed tower, operating at 1.8kPa (absolute pressure), and the bottom temperature of the tower is 135°C. The concentration of caprolactam in the loaded extractant discharged from the extraction tower is 7.5% wt. The caprolactam concentration in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com