Preparation method of amygdalin

A kind of technology of amygdalin and bitter almond, which is applied in the field of preparation of amygdalin, can solve the problems of low sample yield, high pollution, low production efficiency, etc., achieve large single-time preparation, retain biological activity, and avoid sample loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

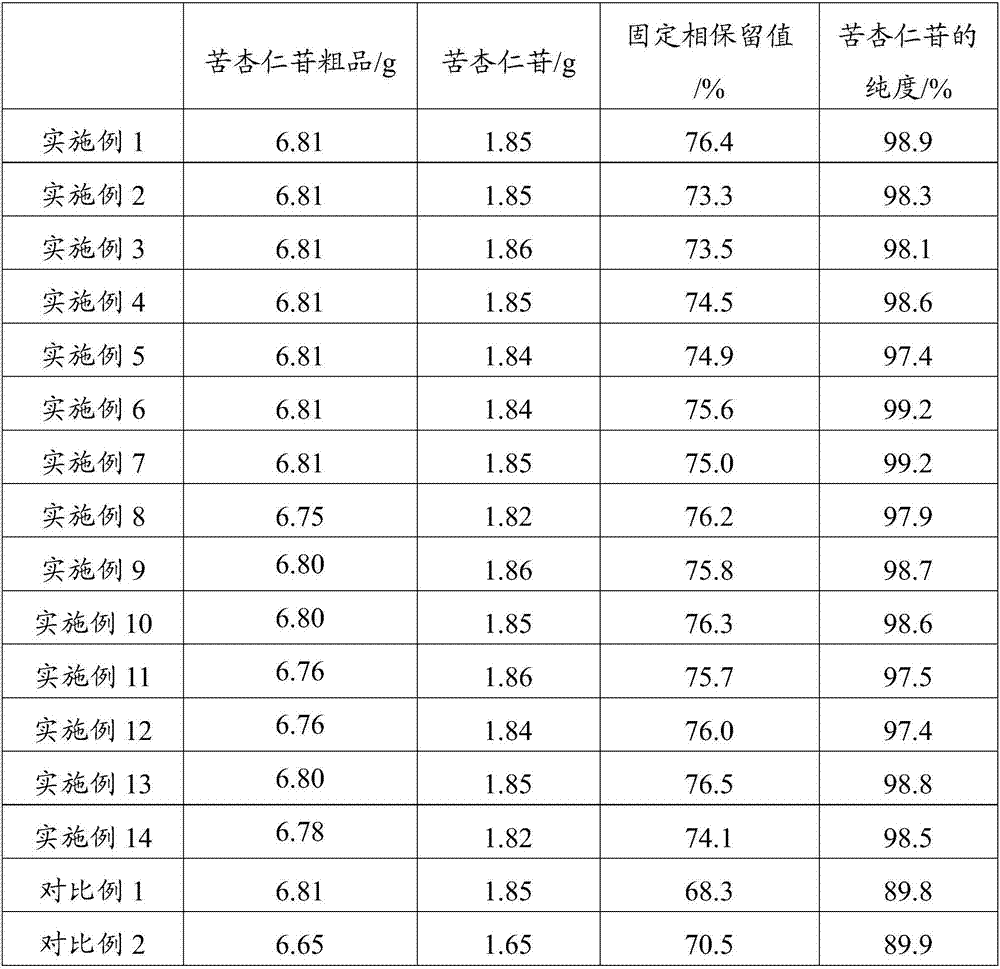

Embodiment 1

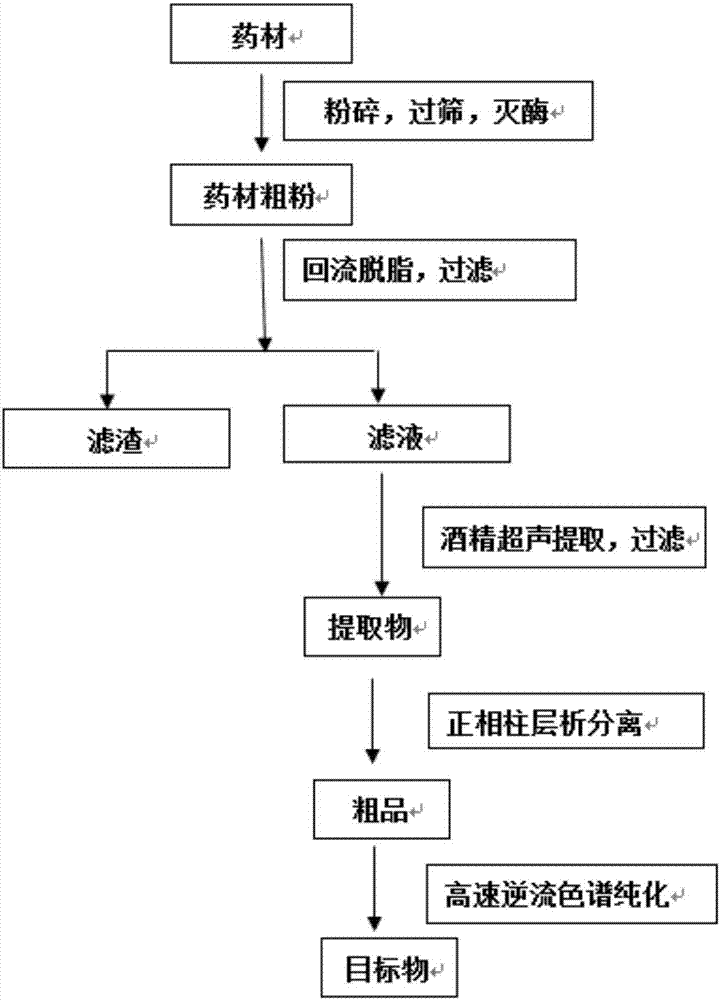

[0034] Prepare amygdalin as follows:

[0035] S1. Take 1.1 kilograms of bitter almond medicinal materials as raw materials, smash through a 60-mesh sieve, inactivate enzymes at 60°C in an oven for 60 minutes, add petroleum ether in a ratio of 1:3, reflux in a water bath at 70°C for 50 minutes, degreasing, pumping The filter residue was collected by filtration, and alcohol was added to dissolve the filter residue at a ratio of material-to-liquid ratio of 1:10. Ultrasonic extraction was performed at a power of 60w and a water bath of 70 ° C for 50 minutes. Filtered, and the filtrate was placed separately. Concentrated to obtain 204.9 g of amygdalin extract.

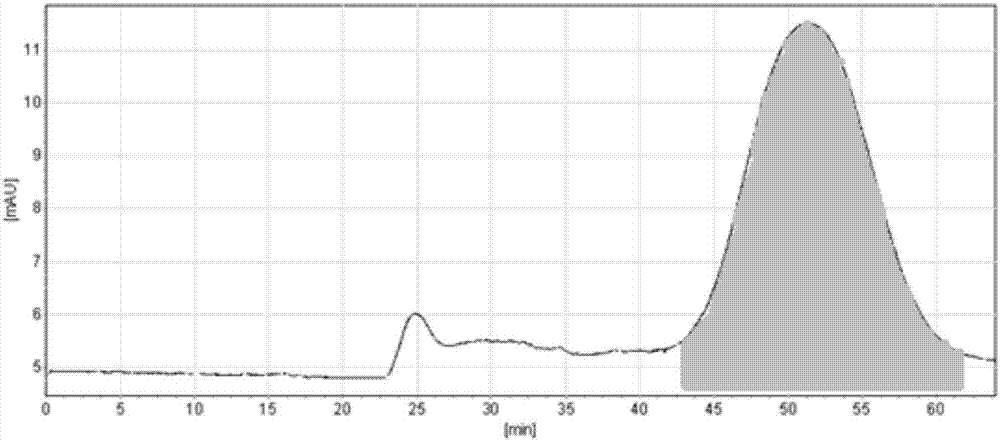

[0036] S2. Separation by normal phase column chromatography: take 27 g of the extract, use ethyl acetate-methanol with a volume ratio of 85:15 as the elution solvent and silica gel as the filler to carry out normal phase column chromatography to separate the extract of the amygdalin , before separation, the filler silica g...

Embodiment 2

[0040] Prepare amygdalin as follows:

[0041] S1. Extract preparation: directly take the extract prepared by the method described in Step 1 of Example 1.

[0042] S2. Separation by normal phase column chromatography: the same as in Example 1.

[0043] S3. Purification by high-speed countercurrent chromatography: similar to Example 1, the difference is that the volume ratio of the solvent system ethyl acetate-n-butanol-water is 0.5:5:4.

Embodiment 3

[0045] Prepare amygdalin as follows:

[0046] S1. Extract preparation: directly take the extract prepared by the method described in Step 1 of Example 1.

[0047] S2. Separation by normal phase column chromatography: the same as in Example 1.

[0048] S3. Purification by high-speed countercurrent chromatography: similar to Example 1, the difference is that the volume ratio of the solvent system ethyl acetate-n-butanol-water is 1.5:1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com