Condensation type waterproof glue for longitudinal watertight cable and preparation method thereof

A longitudinal watertight cable and waterproof glue technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems affecting the waterproof performance and service life of watertight cables, conductor breakage, sliding, etc., to achieve sealing The effect is better, the adhesion is improved, and the effect of vulcanization and crosslinking is promoted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A condensation-type waterproof adhesive for longitudinal watertight cables, characterized in that its raw materials include, by weight, 50 parts of 4,4'-diphenylmethane diisocyanate, 250 parts of polymer polyol, 40 parts of rosin resin, polyethylene 5 parts of alcohol, 5 parts of glutaraldehyde, 5 parts of crosslinking agent, 2 parts of carbon black, 5 parts of magnesium oxide, 3 parts of silane coupling agent, 3 parts of accelerator, and 15 parts of cosolvent.

Embodiment 2

[0020] A condensation-type waterproof adhesive for longitudinal watertight cables, characterized in that its raw materials include: 60 parts by weight of 4,4'-diphenylmethane diisocyanate, 400 parts of polymer polyol, 20 parts of rosin resin, polyethylene 10 parts of alcohol, 3 parts of glutaraldehyde, 15 parts of crosslinking agent, 1 part of carbon black, 8 parts of magnesium oxide, 2 parts of silane coupling agent, 8 parts of accelerator, 5 parts of cosolvent;

[0021] Wherein, polymer polyol is polyester polyol; Cross-linking agent is octyl phenolic vulcanization resin; Accelerator is trimethylol propane; Cosolvent is the mixture of ethyl acetate, cyclohexane and gasoline, ethyl acetate, The weight ratio of cyclohexane and gasoline is 1:2:1.

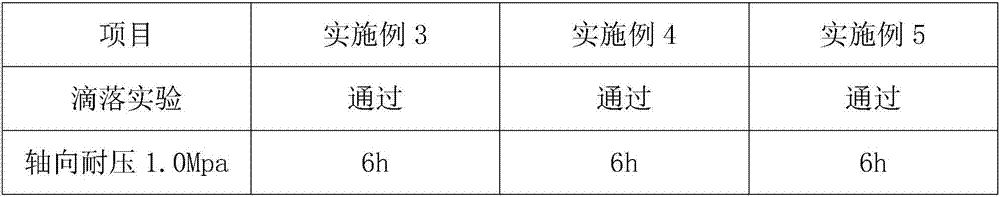

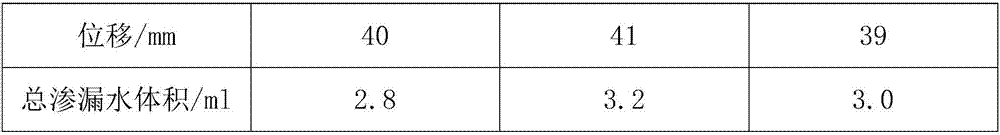

Embodiment 3

[0023] A condensation-type waterproof adhesive for longitudinal watertight cables, characterized in that its raw materials include: 52 parts by weight of 4,4'-diphenylmethane diisocyanate, 300 parts of polymer polyol, 35 parts of rosin resin, polyethylene 6 parts of alcohol, 4.5 parts of glutaraldehyde, 8 parts of crosslinking agent, 1.8 parts of carbon black, 6 parts of magnesium oxide, 2.8 parts of silane coupling agent, 4 parts of accelerator, 12 parts of cosolvent;

[0024] Among them, the polymer polyol is polyether polyol; the crosslinking agent is brominated octyl phenolic resin; the accelerator is polyoxypropylene triol; the cosolvent is a mixture of ethyl acetate, cyclohexane and gasoline, acetic acid The weight ratio of ethyl ester, cyclohexane and gasoline is 1:2:1;

[0025] The condensation-type waterproof glue for longitudinal watertight cables is prepared by the following steps:

[0026] S1. Mix 4,4'-diphenylmethane diisocyanate and polymer polyol according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com