Preparation method of silicon-based surface-enhanced Raman substrate

A surface-enhanced Raman and substrate technology, applied in Raman scattering, ion implantation plating, coating and other directions, can solve the problems of high cost and low price, and achieve the effects of low cost, simple operation and easy control of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

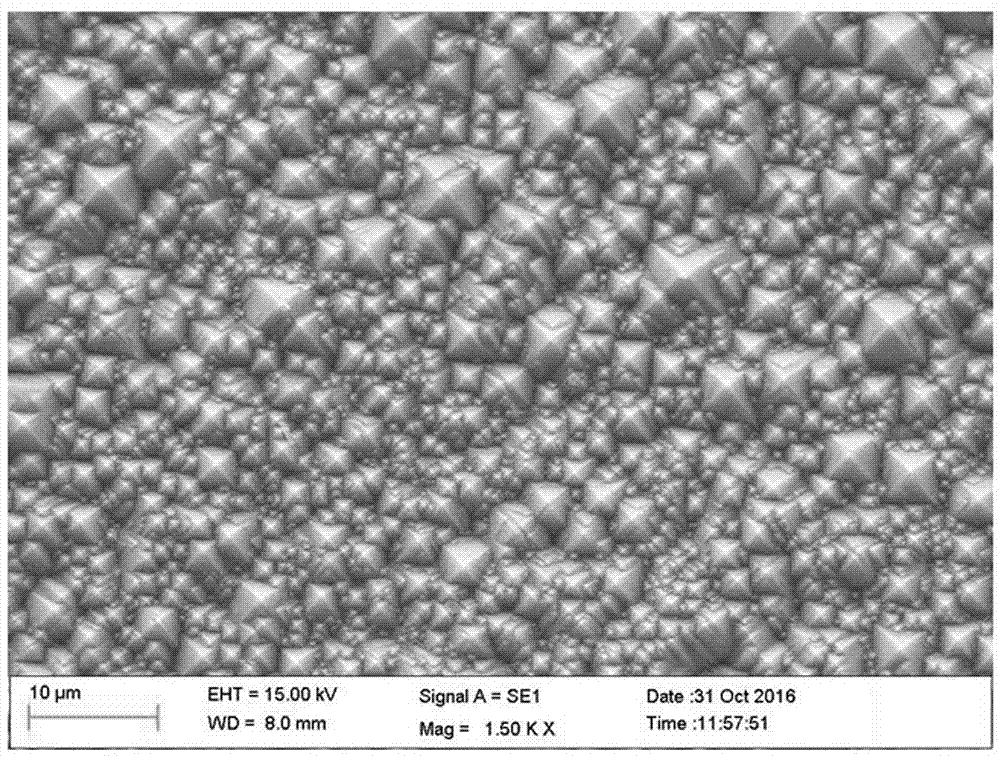

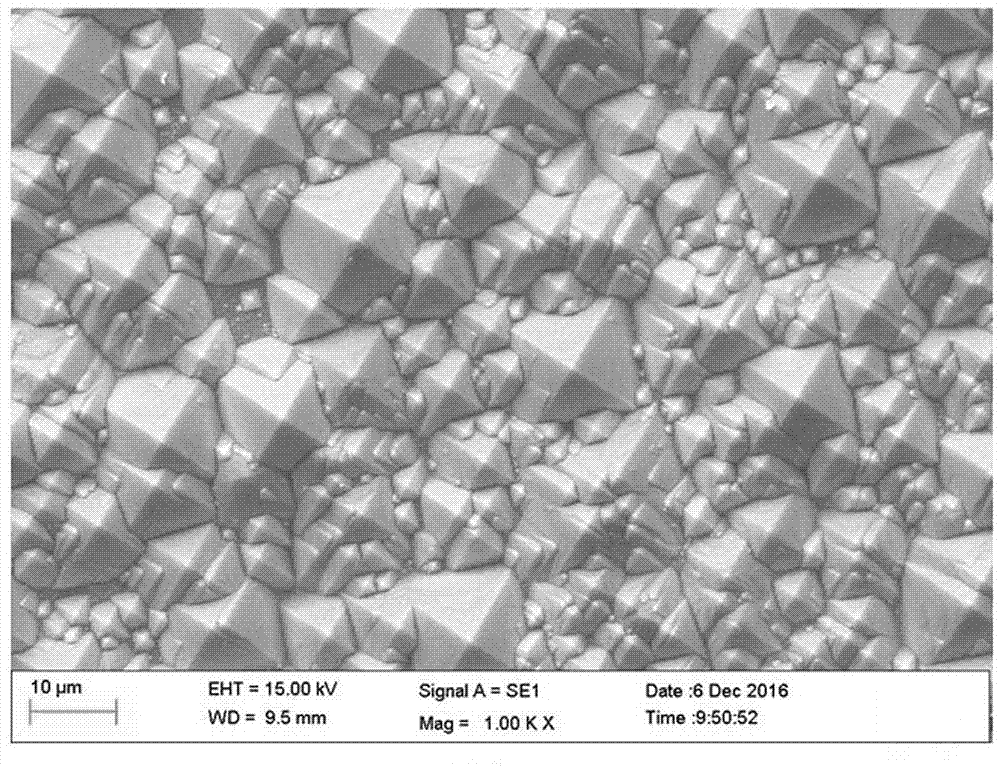

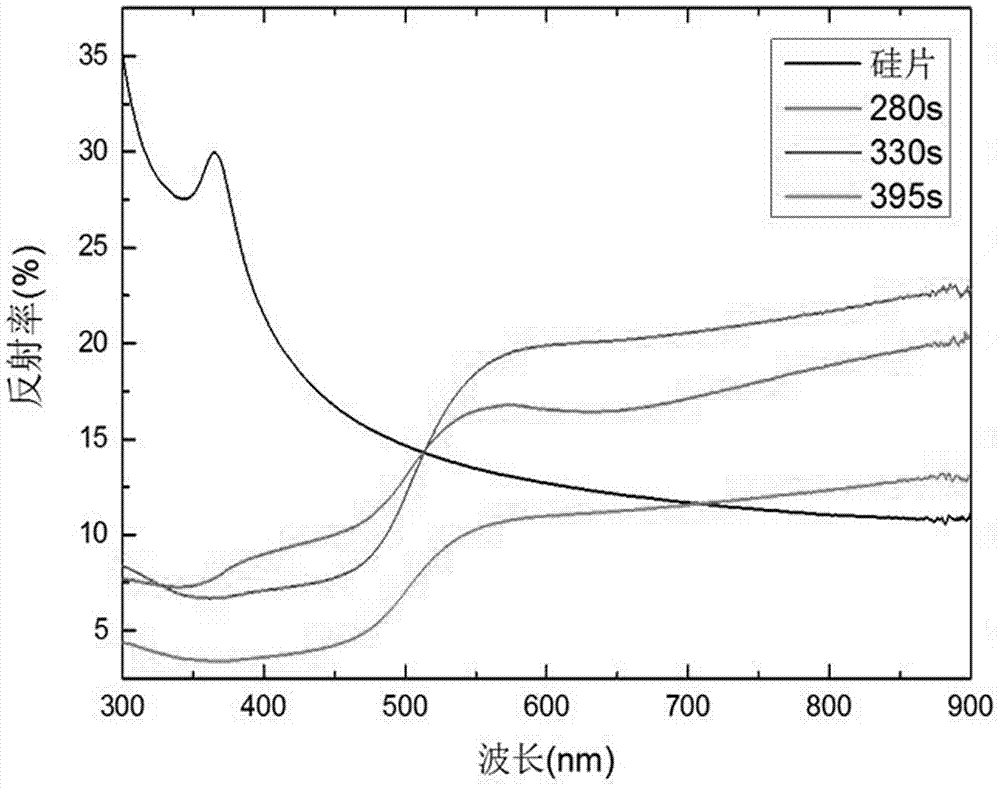

[0026] 1) First cut the single crystal silicon wafer p-type with a resistivity of 1-3Ω·cm into a size of 1.6cm×1.6cm for corrosion experiment, and pretreat the single crystal silicon before the reaction to remove surface impurities and oxidation thing. Clean with a plasma cleaner for 10 minutes, put it into pure water and absolute ethanol successively for 5 minutes, soak in 4% HF for 60 seconds, then clean it with ultrapure water for 5 minutes, and dry it for later use. The resistivity of ultrapure water is 18.25 MΩ•cm;

[0027] 2) The configuration solubility is 10wt%K 2 CO 3 and 2wt%K 2 SiO 3 Solution, the temperature of the magnetic stirrer is set to 85 degrees Celsius, and when the temperature reaches the temperature, put the pretreated monocrystalline silicon into a closed container to react for 20 minutes. After the reaction is completed, use ultrapure water to repeatedly ultrasonically clean it, and dry it for later use;

[0028] 3) Zeiss EVO MA15 scanning electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com