Device and method for extracting refined salt from waste liquid generated during wet ISS-J desulfurization

A technology for extracting essence and waste liquid, which is applied in the field of coal chemical industry and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to enable those skilled in the art to better understand the present invention and to limit the protection scope of the present invention more clearly, the structure and method of the present invention will be described in detail below in conjunction with the accompanying drawings.

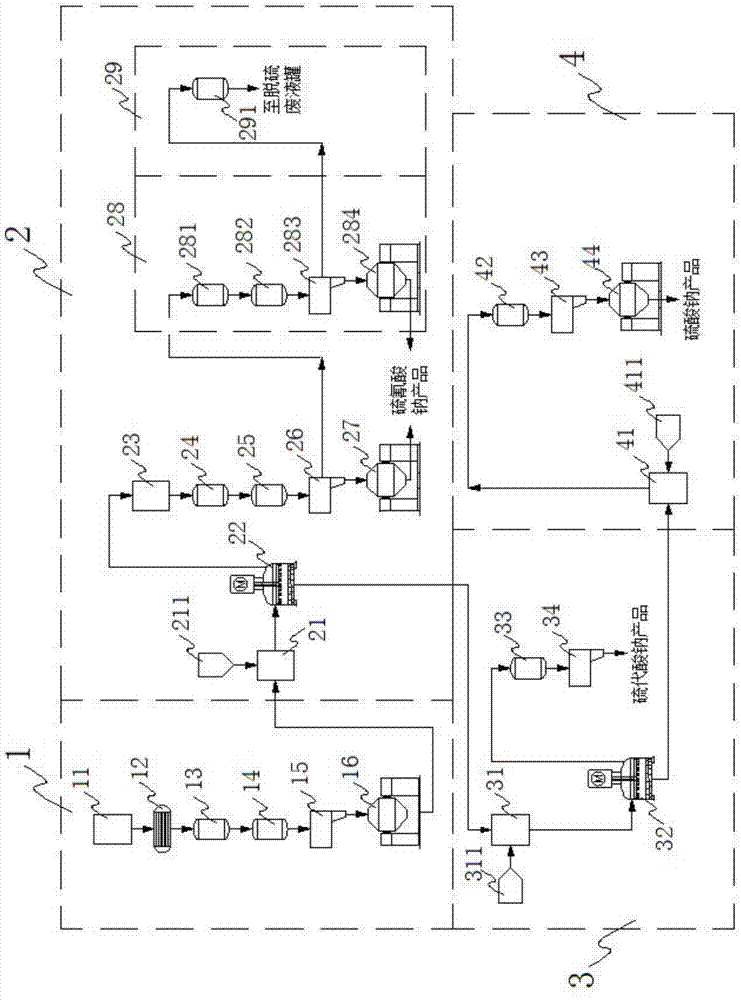

[0055] A device for extracting refined salt from waste liquid produced by wet ISS-J desulfurization, the device includes coarse salt drying component 1, sodium thiocyanate separation and refining component 2, sodium thiosulfate separation and refining component 3, sodium sulfate separation and refining component Component 4 and a solvent recovery component (not shown in the figure); the waste liquid produced from the desulfurization process catalyzed by the wet method ISS-J type desulfurization catalyst is transferred to the coarse salt drying component 1 for processing, and the waste liquid after the treatment of the coarse salt drying component 1 The material is transferred to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com