Preparation method and application of biomass-derived ultra-high specific surface area activated carbon

A technology of ultra-high specific surface area and activated carbon, applied in chemical instruments and methods, carbon compounds, non-aqueous electrolyte batteries, etc., can solve the problems of waste of resources, environmental pollution, etc., and achieve the goals of improving performance, enriching materials, and preventing the accumulation of sulfur Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] 1. Carbonization:

[0040] Weigh the dried palm shell raw material and place it in a quartz crucible, then put it into a tube furnace for heating, and in a nitrogen-enclosed environment, raise the temperature in the tube furnace to 500±20 °C at a heating rate of 5 °C / min Carbonization treatment 2h.

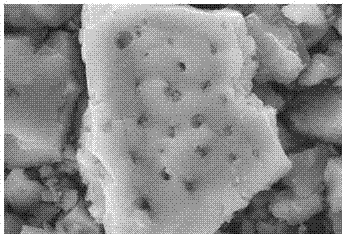

[0041] After the completion, let it stand and cool to normal temperature, then take it out to obtain black palm shell carbonized material, which is crushed and sieved to obtain carbonized palm shell powder with a particle size of ≤10 μm, and set aside.

[0042] 2. Dipping:

[0043] Weigh the carbonized palm shell powder and mix it with KOH at a mass ratio of 3:1, add an appropriate amount of distilled water, stir evenly, and place it in an oven at 100±10°C to dry to obtain palm shell powder containing an activator.

[0044] 3. Activation:

[0045] Put the palm shell powder containing the activator in a nickel crucible, and then put it into a tube furnace. Under nitrogen ...

example 2

[0050] 1. Carbonization:

[0051] Weigh the dried palm shell raw material and place it in a quartz crucible, then put it into a tube furnace for heating, and in a nitrogen-enclosed environment, raise the temperature in the tube furnace to 500±20 °C at a heating rate of 5 °C / min Carbonization treatment 3h.

[0052] After the completion, let it stand and cool to normal temperature, then take it out to obtain black palm shell carbonized material, which is crushed and sieved to obtain carbonized palm shell powder with a particle size of ≤10 μm, and set aside.

[0053] 2. Dipping:

[0054] Weigh the carbonized palm shell powder and mix it with KOH at a mass ratio of 5:1, add an appropriate amount of distilled water, stir evenly, and dry in an oven at 100±10°C to obtain palm shell powder containing an activator.

[0055] 3. Activation:

[0056] Put the palm shell powder containing the activator in a nickel crucible, and then put it into a tube furnace. Under a nitrogen atmosphere...

example 3

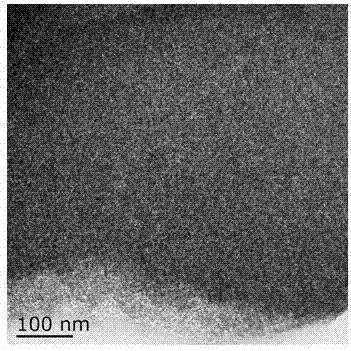

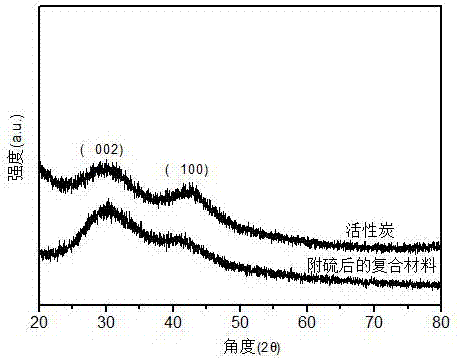

[0061] Biomass-derived ultra-high specific surface area activated carbons were prepared in a similar manner to the above example, and were marked as: activated carbon 7#, activated carbon 8#, and activated carbon 9#.

[0062] 2. Application:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com